Ethylene glycol production wastewater treatment method

A technology for producing wastewater and treatment methods, applied in water/sewage treatment, natural water treatment, heating water/sewage treatment, etc., to achieve the effects of reducing pressure, cost and investment, and reducing the amount of oxidant and reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

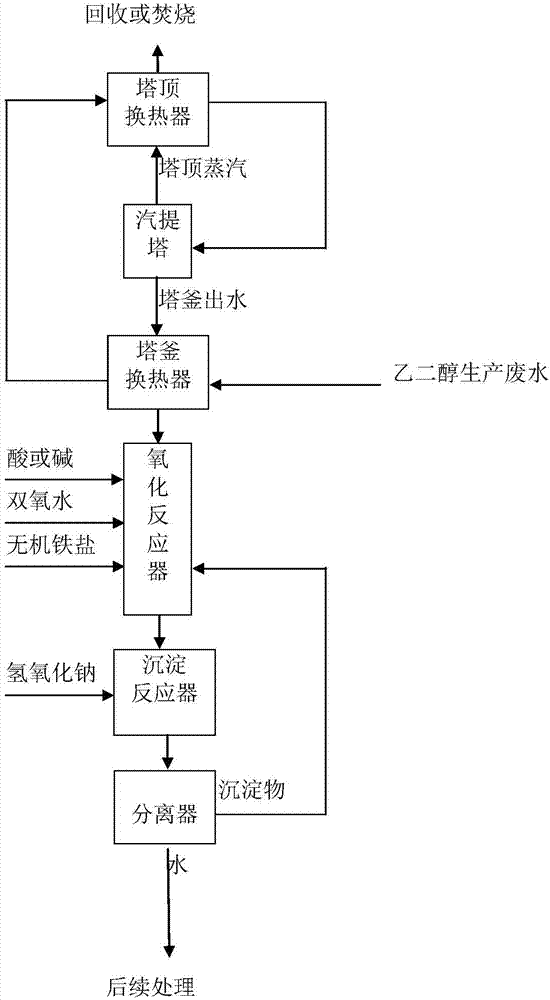

Image

Examples

Embodiment 1

[0050] A company’s oxalate method ethylene glycol production wastewater has a pH value of 2.0, a COD of 14000 mg / L, and a TOC of 4000 mg / L. 1,4-dioxane content 5000mg / L. The total nitrogen content is 2000mg / L.

[0051] Under the conditions that the temperature of the stripper tower kettle is controlled at 108°C, the pressure at the top of the stripper tower is controlled at normal pressure, the number of theoretical plates of the stripper tower is 15, and the outflow of the tower top of the stripper tower is 12% of the water entering the tower, The content of dioxane in the effluent water of the stripping tower drops to less than 120mg / L.

[0052] Next, high-temperature catalytic oxidation treatment is carried out on the wastewater. The temperature of the catalytic oxidation reaction system is controlled at 90°C, the pressure is normal pressure, the pH is adjusted to 3.0 with alkali, the total iron content is 100 mg / L, and the amount of 27.5% hydrogen peroxide is calculated a...

Embodiment 2

[0057] A company's coal-based ethylene glycol production wastewater has a pH value of 9.0, a COD of 20,000 mg / L, and a TOC of 6,000 mg / L. The content of 1,4-dioxane is 7000mg / L, and the content of total nitrogen is 3000mg / L.

[0058] Under the conditions that the temperature of the stripper tower kettle is controlled at 102°C, the pressure at the top of the stripper tower is controlled at normal pressure, the number of theoretical plates of the stripper tower is 10, and the outflow of the tower top of the stripper tower is 10% of the water entering the tower, The content of dioxane in the effluent water of the stripping tower drops to less than 200mg / L.

[0059] Carry out catalytic oxidation treatment to this waste water, the temperature control of catalytic oxidation reaction system is 80 ℃, pressure is normal pressure, pH is adjusted to be 4.5 with sulfuric acid, the consumption of total iron content is 50mg / L, 27.5% hydrogen peroxide by every L waste water (steam Add 10ml ...

Embodiment 3

[0064] A company's coal-based ethylene glycol production wastewater has a pH value of 9.0, a COD of 10,000 mg / L, and a TOC of 3,000 mg / L. The content of 1,4-dioxane is 2000mg / L, and the content of total nitrogen is 1500mg / L.

[0065] Under the conditions that the temperature of the stripper tower is controlled at 120°C, the pressure at the top of the stripper is controlled at normal pressure, the number of theoretical plates of the stripper is 20, and the outflow of the top of the stripper is 20% of the water entering the tower, The content of dioxane in the effluent water of the stripping tower drops to less than 80mg / L.

[0066] This waste water is carried out catalytic oxidation treatment, and the temperature control of catalytic oxidation reaction system is 99 ℃, and pressure is normal pressure, and pH is adjusted to 2.0 with sulfuric acid, and total iron content is 200mg / L, the consumption of 27.5% hydrogen peroxide by every L waste water (steam Add 5ml of water from the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap