High-toughness and abrasion-resistant medical gloves

A high-toughness, glove technology, applied in the field of medical supplies, can solve the problems that gloves are difficult to meet the medical environment, single-use gloves have single performance, and are prone to tearing plastics, etc., to reduce sweating, easy to obtain, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

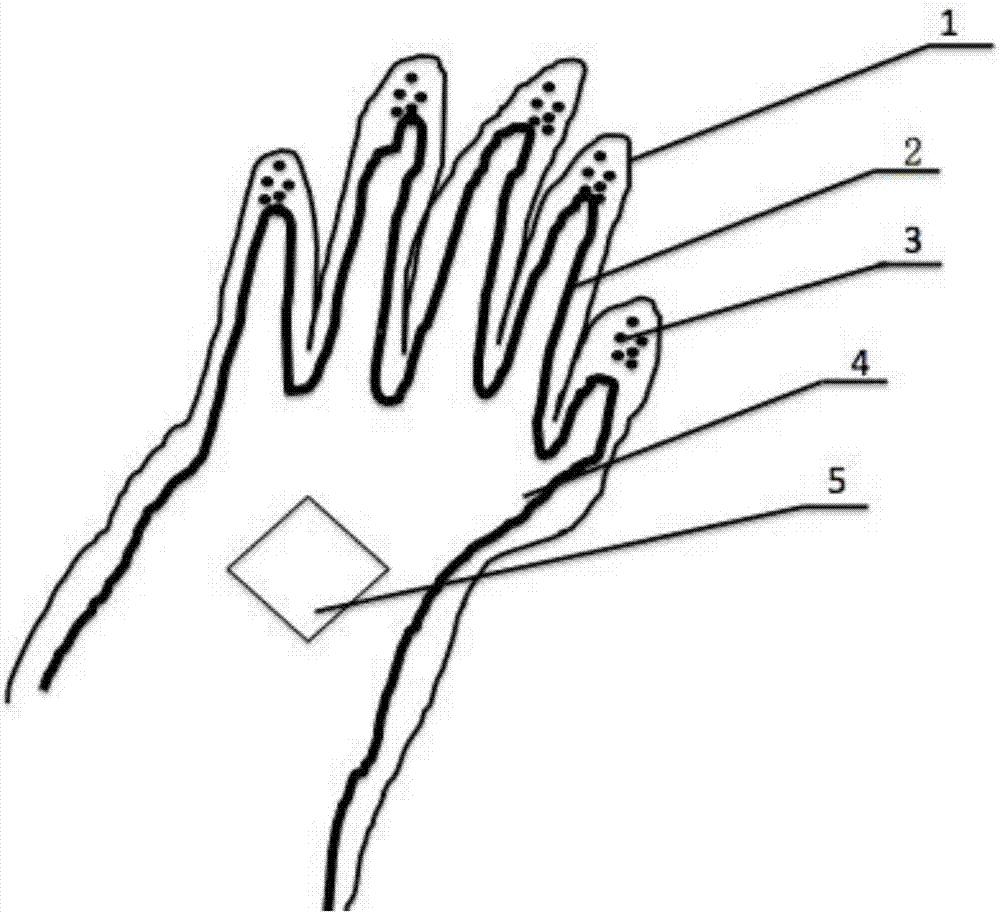

[0042] Such as figure 1 As shown, a high-toughness and wear-resistant medical glove includes a sealed and wear-resistant outer layer 1 and a sealed and tough inner layer 2. Anti-slip floating points 3 are arranged on the belly of five fingers on the sealed and wear-resistant outer layer 1, and a sealed and tough inner layer 2 A layer of air-permeable layer 4 is arranged on the top, and a simple pasting board 5 is arranged on the back of the sealed and wear-resistant outer layer 1 .

[0043] The sealing wear-resistant outer layer 1 includes the following components: by weight components,

[0044] Low-density polyethylene: 78 parts

[0045] Sodium sulfate: 3 parts

[0046] Aluminum Chlorohydrate Glycol: 3 parts

[0047] Sodium oleate: 5 parts

[0048] Polyurethane: 15 parts

[0049] The sealing toughness inner layer 2 comprises the following components: by weight components,

[0050] Polypropylene: 30 parts

[0051] Sodium sulfate: 3 parts

[0052] PVC: 3 parts

[0053]...

Embodiment 2

[0074] Such as figure 1 As shown, a high-toughness and wear-resistant medical glove includes a sealed and wear-resistant outer layer 1 and a sealed and tough inner layer 2. Anti-slip floating points 3 are arranged on the belly of five fingers on the sealed and wear-resistant outer layer 1, and a sealed and tough inner layer 2 A layer of air-permeable layer 4 is arranged on the top, and a simple pasting board 5 is arranged on the back of the sealed and wear-resistant outer layer 1 .

[0075] The sealing wear-resistant outer layer 1 includes the following components: by weight components,

[0076] Low-density polyethylene: 60 parts

[0077] Sodium sulfate: 1 part

[0078] Aluminum Chlorohydrate Glycol: 2 parts

[0079] Sodium oleate: 1 part

[0080] Polyurethane: 15 parts

[0081] The sealing toughness inner layer 2 comprises the following components: by weight components,

[0082] Polypropylene: 30 parts

[0083] Sodium sulfate: 1 part

[0084] PVC: 2 parts

[0085] St...

Embodiment 3

[0106] Such as figure 1 As shown, a high-toughness and wear-resistant medical glove includes a sealed and wear-resistant outer layer 1 and a sealed and tough inner layer 2. Anti-slip floating points 3 are arranged on the belly of five fingers on the sealed and wear-resistant outer layer 1, and a sealed and tough inner layer 2 A layer of air-permeable layer 4 is arranged on the top, and a simple pasting board 5 is arranged on the back of the sealed and wear-resistant outer layer 1 .

[0107] The sealing wear-resistant outer layer 1 includes the following components: by weight components,

[0108] Low-density polyethylene: 70 parts

[0109] Sodium sulfate: 3 parts

[0110] Aluminum Chlorohydrate Glycol: 3 parts

[0111] Sodium oleate: 4 parts

[0112] Polyurethane: 18 parts

[0113] The sealing toughness inner layer 2 comprises the following components: by weight components,

[0114] Polypropylene: 38 parts

[0115] Sodium sulfate: 3 parts

[0116] PVC: 3 parts

[0117]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com