Pouring method of epoxy resin AB glue in jewelry manufacturing

A technology of epoxy resin and pouring method, which is applied in the direction of epoxy resin glue, jewelry, clothing, etc., and can solve problems such as easy formation of bubbles, white spots of jewelry, and influence on appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

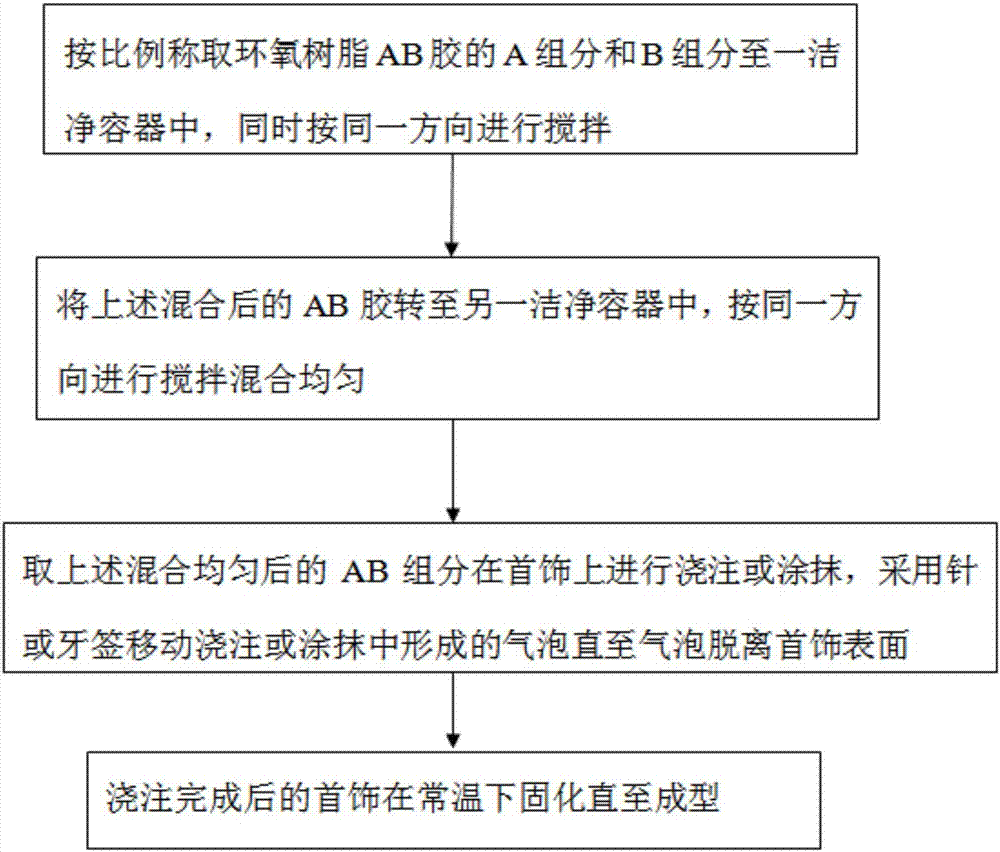

[0019] Refer to attached figure 1 , the embodiment of the present invention provides a kind of pouring method of epoxy resin AB glue in jewelry making, comprises the following steps:

[0020] (1) Weigh component A and component B of epoxy resin AB glue into a clean container, and stir in the same direction at the same time; stirring in the same direction is conducive to the combination of small bubbles generated during the stirring process into larger bubbles and escape;

[0021] Wherein, the weight ratio of component A to component B is 3:1-1.5, and the composition and mass parts of said component A are: 80-100 parts of bisphenol A epoxy resin, 20 parts of bisphenol F epoxy resin ~40 parts, 5~15 parts of nano-scale silica / epoxy polymer toughening agent, 20~60 parts of filler, the composition of the B component is: 90~100 parts of polyetheramine, 5 parts of amino-terminated polyether ~10 parts, accelerator 1~2 parts; stirring time is 30s~60s; too long stirring time will easi...

Embodiment 2

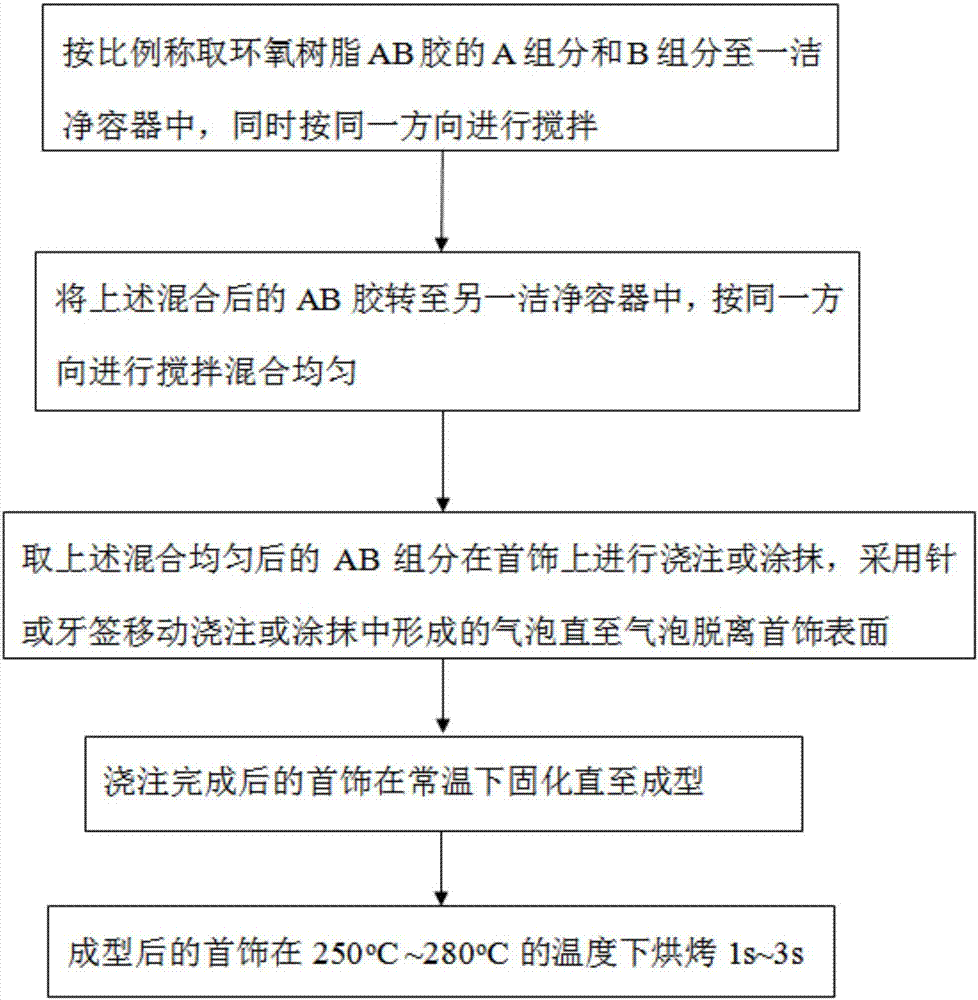

[0027] Refer to attached figure 2 , the embodiment of the present invention provides a kind of pouring method of epoxy resin AB glue in jewelry making, comprises the following steps:

[0028] (1) Weigh components A and B in proportion to a clean container, and stir in the same direction at the same time;

[0029] (2) Put the above mixed AB glue into another clean container, stir and mix evenly in the same direction;

[0030] (3) Take the uniformly mixed AB component and pour or smear it on the jewelry, and use a needle or toothpick to move the air bubbles formed during the pouring or smearing until the air bubbles leave the jewelry surface;

[0031] (4) The jewelry after pouring is solidified at room temperature until it is formed;

[0032] (5) The molded jewelry is baked at a temperature of 250°C to 280°C for 1s to 3s. All the other are the same as embodiment one.

[0033] After the cured jewelry is damp in the environment and forms white spots, it can be baked at high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com