LED automobile lamp of innovative structure

A technology of LED car lamps and LED lamp beads, which is applied in semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, lighting devices, etc., can solve problems such as complex assembly process and complex structure, reduce light attenuation, improve Production efficiency, the effect of simple production structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

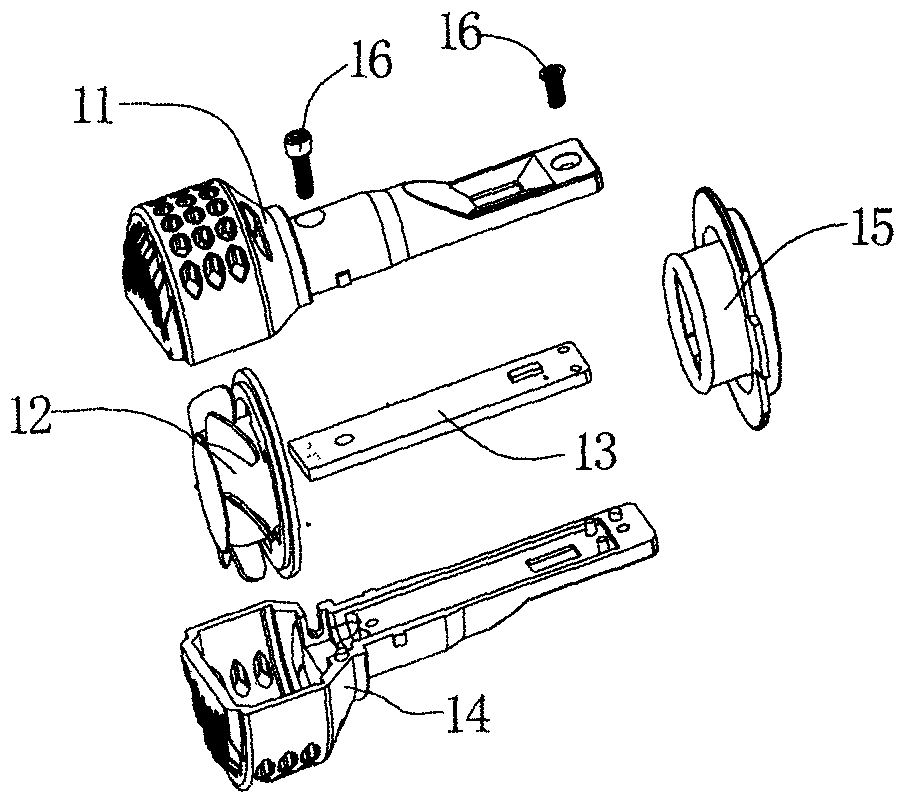

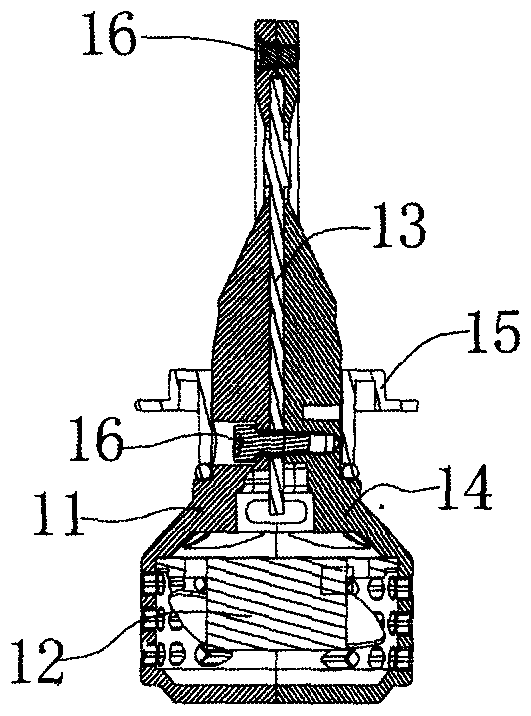

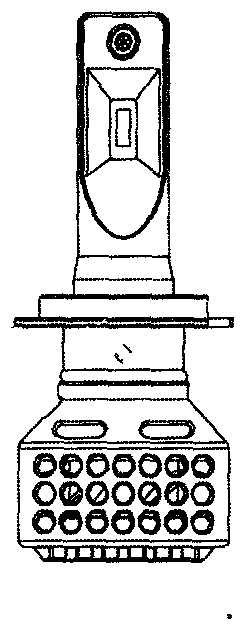

[0016] refer to figure 1 figure 2 image 3 In this embodiment, an LED car lamp with an innovative structure includes a first heat sink 11, a second heat sink 14, a heat dissipation fan 12, and an LED lamp bead board 13. The bottom of the first heat sink 11 and the second heat sink 14 are made of A number of heat dissipation ventilation holes are arrayed along the circumference, and grooves are arranged inside the first heat sink 11 and the second heat sink 14. The circular bottom of the heat dissipation fan 11 is stuck in the groove, and the LED lamp bead board 13 is placed in the first heat dissipation In the middle of the radiator 11 and the second radiator 14, the first radiator 11 and the second radiator 14 are pasted on both sides. A fixing hole is provided on the first radiator 11, and an internal thread hole is provided on the second radiator 14. Through Fix the screw 16 to connect the first heat sink 11 and the second heat sink 14, and connect the LED lamp bead boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com