A friction rod transmission device

A transmission device, friction rod technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of difficult to eliminate the return gap, peeling off of the polished rod, incapable of high load, etc., to improve the transmission efficiency and stability, reduce fatigue damage, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

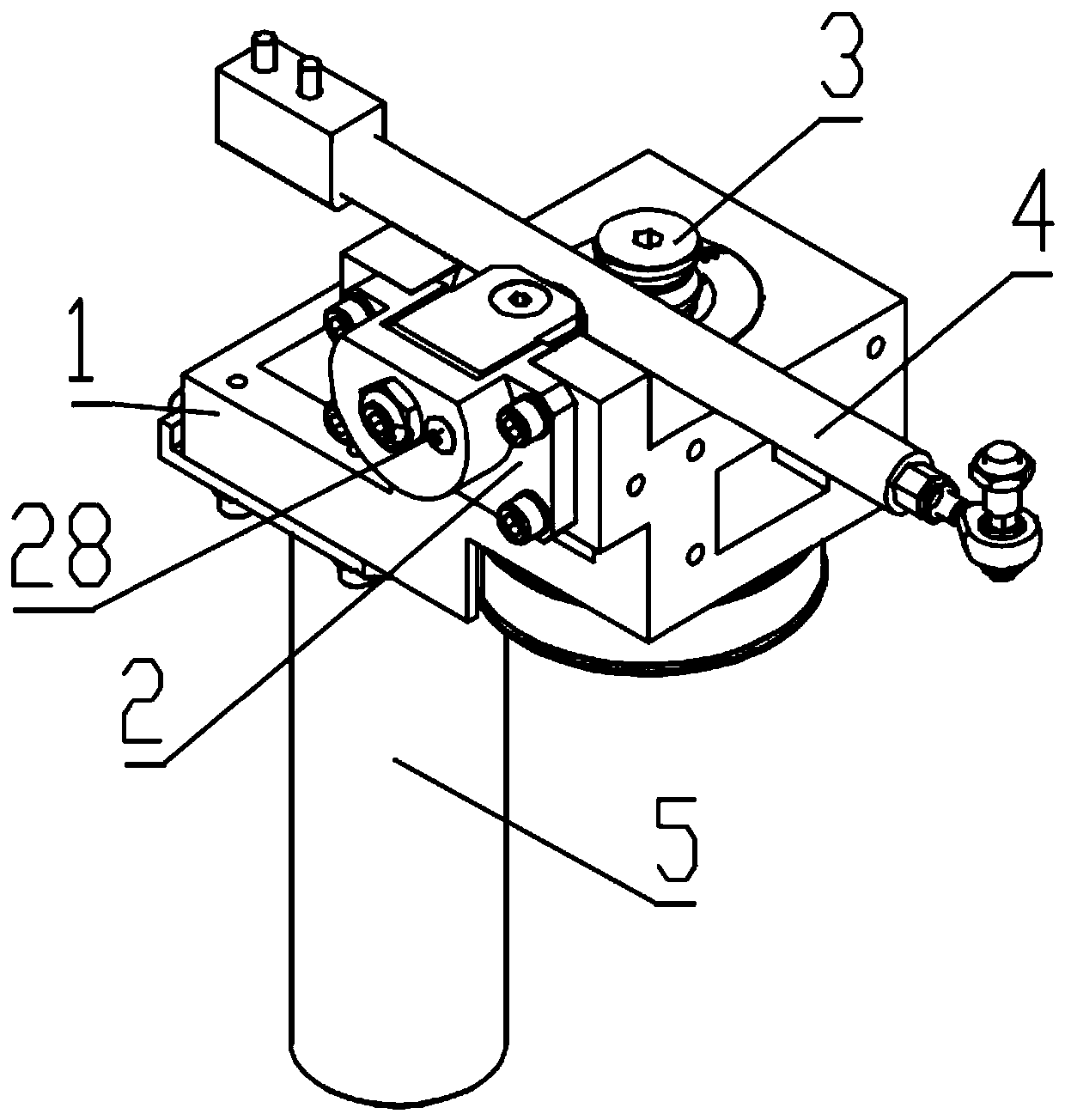

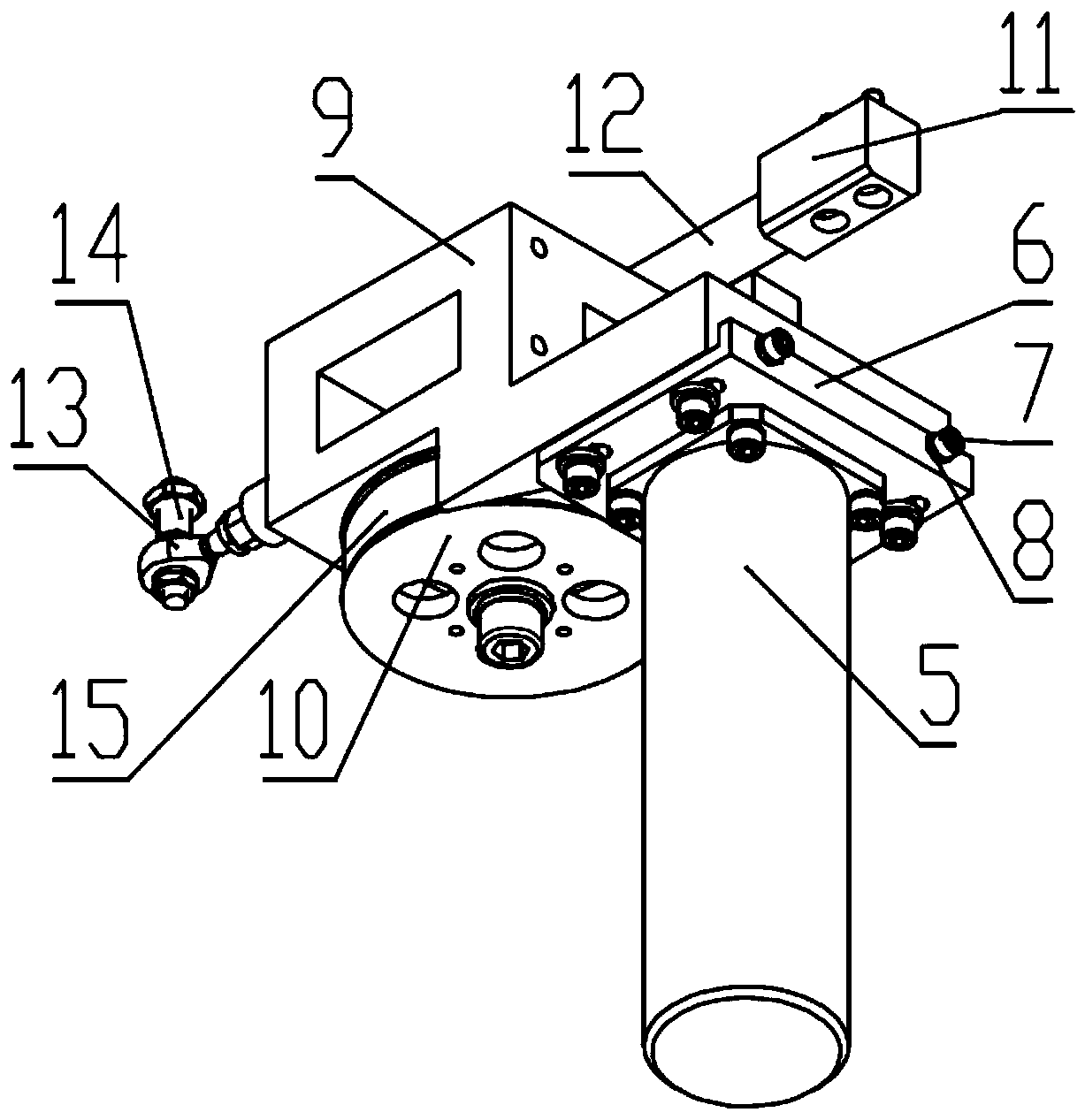

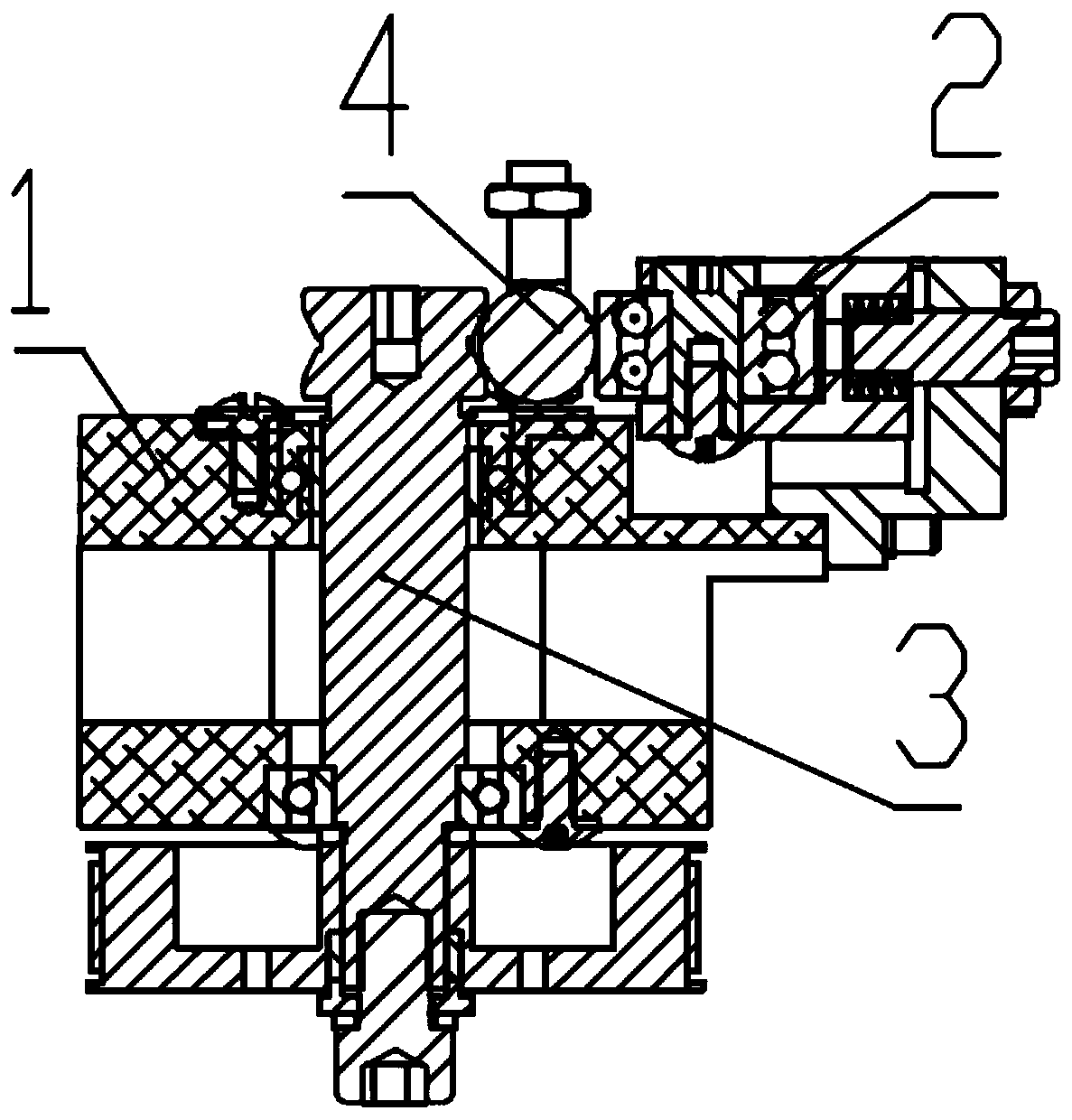

[0034] like Figure 1 to Figure 3 As shown, a friction rod transmission device shown in this embodiment includes a box body 9 and a V-shaped wheel assembly 3 installed on the box body 9, a friction rod assembly 4, a pressing wheel assembly 2 and a servo motor 5, the servo The motor 5 is set at the lower end of the box body 9 and is connected to the V-shaped wheel assembly 3. The pressing wheel assembly 2 is set at the upper end of the box body 9 and clamps the friction rod assembly 4 with the V-shaped wheel assembly 3. The V-shaped wheel assembly is driven by the servo motor 5. The wheel assembly 3 rotates, and the V-shaped wheel assembly 3 then generates static friction with the friction rod assembly 4. The static friction generates a forward thrust on the friction rod assembly 4, pushing the friction rod assembly 4 forward. When the friction rod assembly 4 moves to the specified position, an active force in the opposite direction is generated to force the friction rod assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com