Sample quick assembling and heating system based on plane collision impact test

An impact test and sample technology, which is applied in the field of artillery or gas cannon high-temperature test, can solve the problems of heating uniformity deviation and slow heating rate, and achieve the effects of small heating temperature deviation, reduced temperature inhomogeneity, and good test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

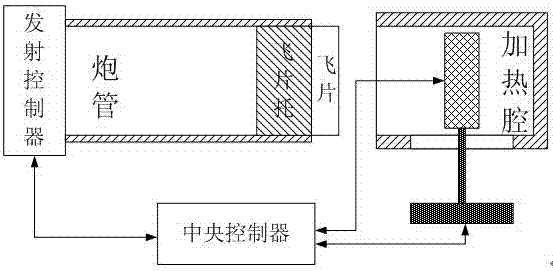

[0020] Such as figure 1 As shown, it is a schematic structural diagram of the existing test system, which includes a launch controller, a gun barrel, a central controller, and a heating chamber. The signal line of the central controller is connected to the launch controller, wherein the heating chamber is arranged The nozzle is directly opposite, and is always in a heating state, while the sample is set in the heating chamber and supported by a retractor, so that the sample is always in the heating chamber. But because this setup must have two side openings, one side needs to face the gun barrel nozzle, and the other side needs to be used to support the sample, and if the heating chamber has two open sides, it means that the air Convection can be formed on both sides. This means that the hea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap