Optimum design method for extra-high voltage multi-level flexible direct-current power transmission operation interval

A modular multi-level, flexible DC power transmission technology, applied in the direction of converting AC power input to DC power output, power transmission AC network, electrical components, etc., can solve the problem of increasing the construction area of the converter station and the original Problems such as performance change and increase in component volume, etc., to achieve the effects of guaranteed performance, optimized power operation range, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

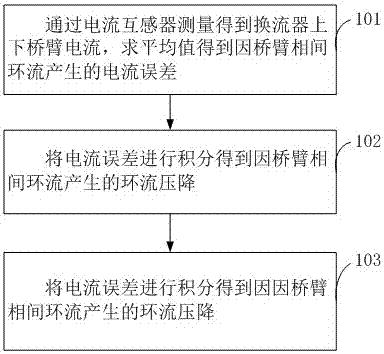

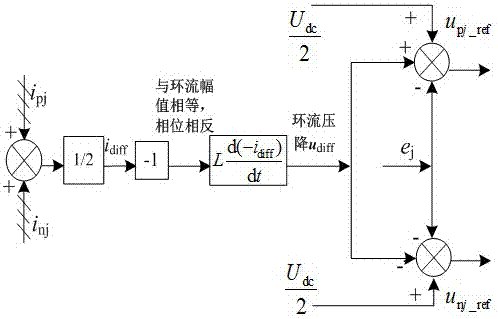

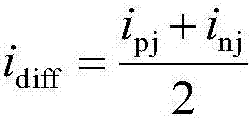

[0044] The existing main method for optimal control of the inverter operating range mainly adopts the method of increasing the capacitance value of the inverter sub-module or changing the reactance value of the bridge arm. Increasing the volume of the element itself, and then increasing the construction area of the converter station, the project is complicated and the investment is high, and the original performance of the converter will be changed at the same time. Therefore, it is necessary to ensure that the original performance of the converter does not change, and to optimize its operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com