Device for removing heavy impurities in reconstituted tobacco slurry

A technology for reconstituting tobacco leaves and heavy impurities, applied in the direction of sedimentation tanks, etc., can solve the problems of investment in additional impurities removal equipment, implementation period limitation of installation space, mixing of hard impurities, increased investment in maintenance and renewal, etc., and achieves good impurities removal effect. , prolong the service life, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

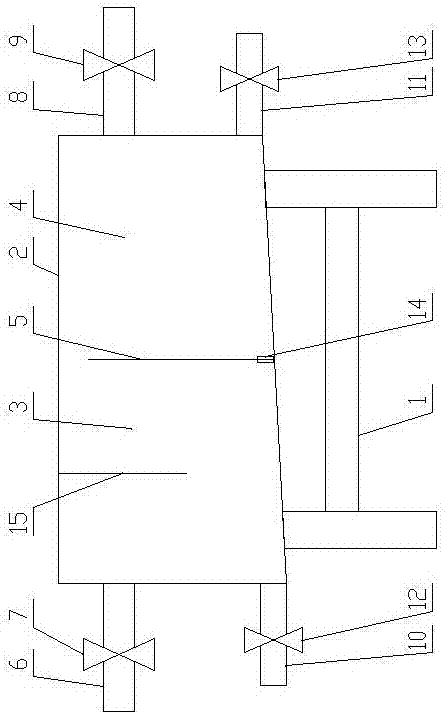

[0014] Such as figure 1 As shown, the removal device of heavy impurities in the reconstituted tobacco leaf slurry of the present invention includes a support 1 and an open-top impurity removal container 2 arranged on the support 1, and the impurity removal container 2 is provided with an internal compartment for the impurity removal container 2. It is divided into the partition plate 5 of the left sedimentation chamber 3 and the right sedimentation chamber 4. The partition board 5 is arranged in the vertical direction. The upper left side of the impurity removal container 2 is connected with a slurry inlet pipe joint 6 communicating with the left sedimentation chamber 3. The impurity removal container 2 The upper part of the right side is connected with a slurry outlet pipe joint 7 communicating with the right sedimentation chamber 4, a slurry inlet valve 8 is arranged on the slurry inlet pipe joint 6, a slurry outlet valve 9 is arranged on the slurry outlet pipe joint 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com