Self-generating chilling method for controlling deformation of large complex aluminum copper alloy

A technology of aluminum-copper alloy and self-generating cold iron, which is applied in the field of machinery, can solve problems such as casting deformation, achieve the effects of reduced radial deformation, minimized internal stress and deformation, good cooling effect and good deformation resistance of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

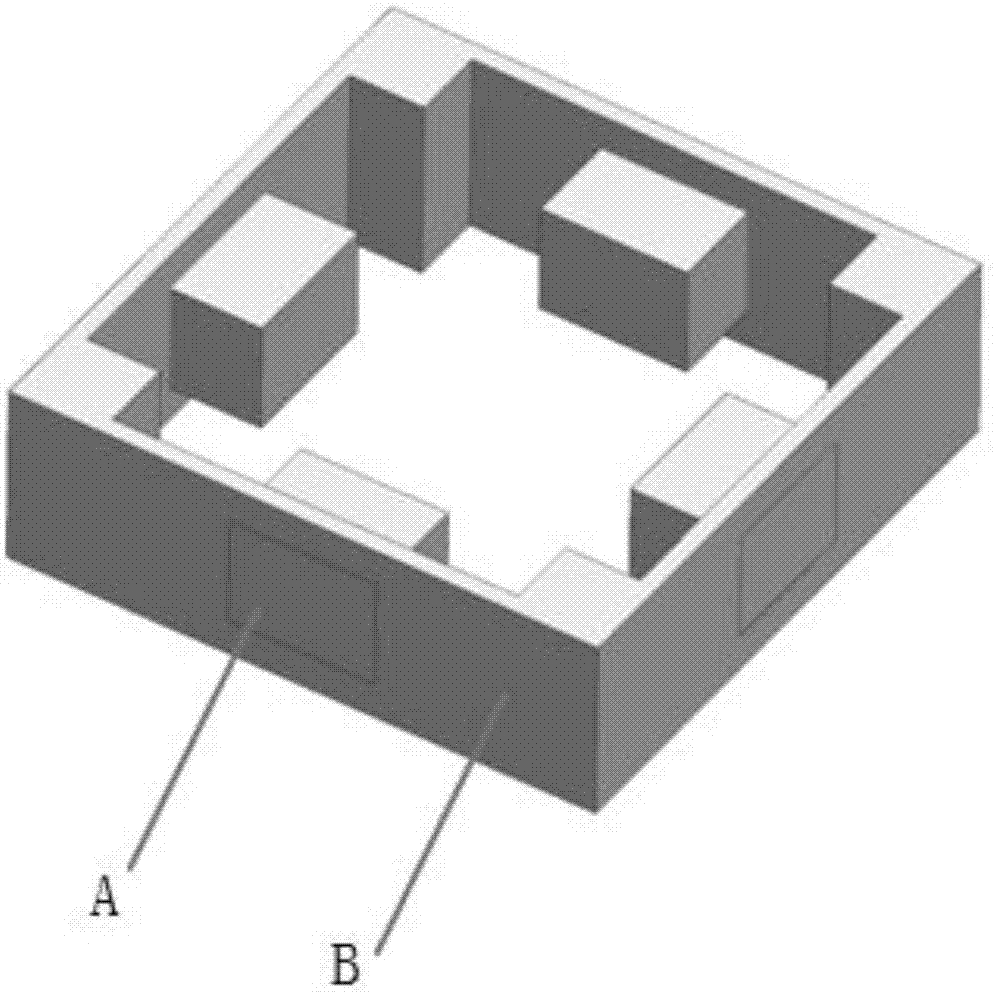

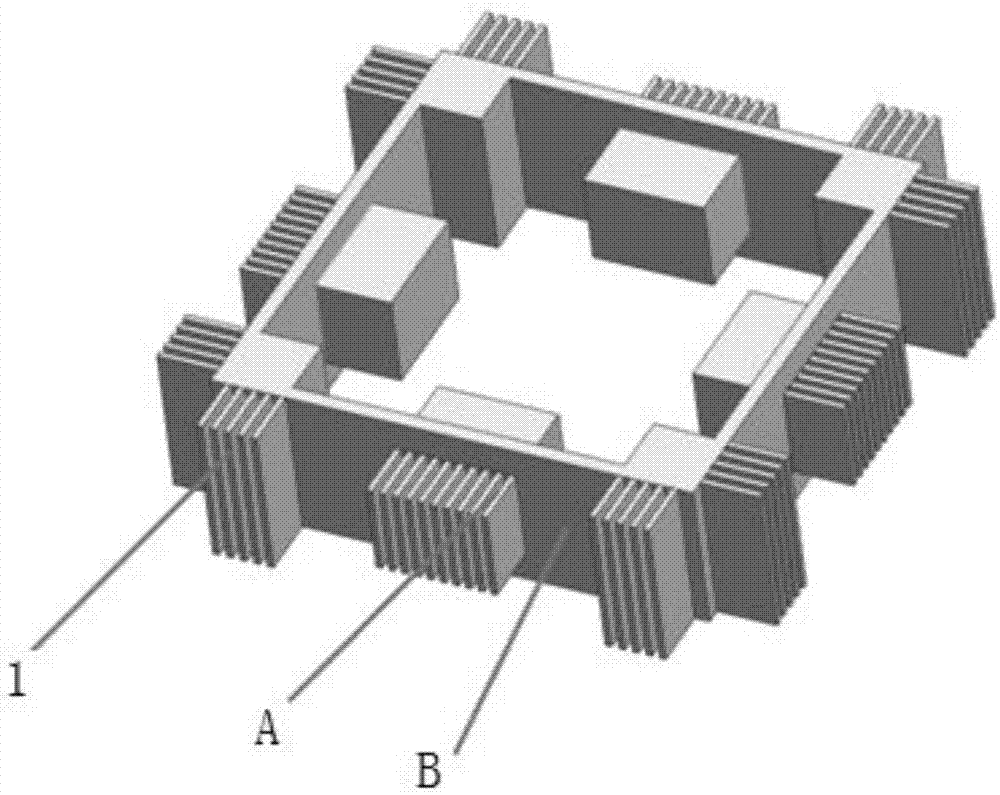

[0012] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment mode, a kind of self-generated quenching method for controlling the deformation of large complex aluminum-copper alloy described in this embodiment mode is realized through the following steps:

[0013] Step 1. Partially divide large complex aluminum-copper alloy castings into A zone and B zone, and determine whether A zone and B zone are suitable for using self-generated chill iron 1;

[0014] Step 2, calculating the quantity of required self-generated cold iron 1;

[0015] Step 3, setting the self-generated cold iron 1 in the corresponding area;

[0016] Step 4, forming the cavity position of the self-generated cold iron 1 .

[0017] In this embodiment, the self-generating chill 1 is directly formed during the pouring process and is directly connected with the casting. The composition is exactly the same as that of the casting, and the Cu content ranges from 2.0wt.%. The radi...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, in step 1 of an autogenous quenching method for controlling deformation of a large complex aluminum-copper alloy described in this embodiment, the wall thickness H of the A zone is greater than the wall thickness h of the B zone.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the use condition of the self-generating cold iron 1 of an autogenous chilling method for controlling the deformation of a large complex aluminum-copper alloy described in this embodiment is H≧3.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com