Music bell vibrating plate machining technology and special tool

A processing technology and vibrating piece technology, which is applied to manufacturing tools, metal processing equipment, milling cutters, etc., can solve the problems of hard sounding, soft and loud sound, and difficult to reach the center distance of sound keys, so as to achieve soft sound. The effect of pleasing to the ear, reducing the difficulty of processing, and improving the quality of the sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

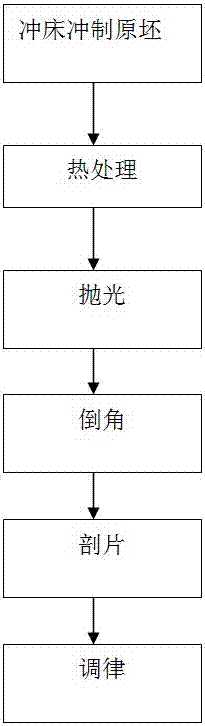

[0025] Process flow of the present invention, as figure 1 Shown, the technological process of prior art, such as figure 2 shown.

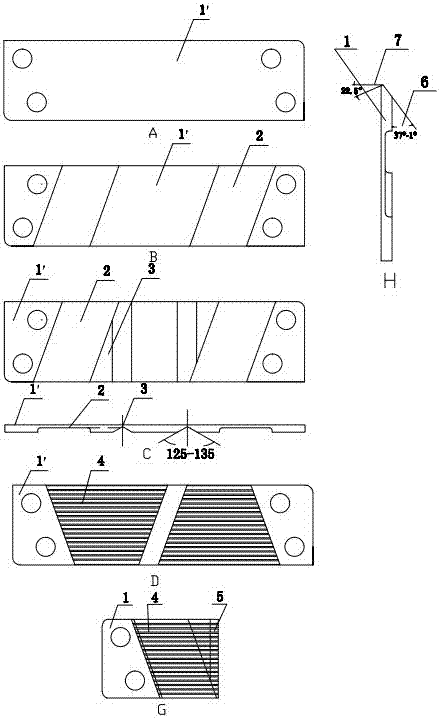

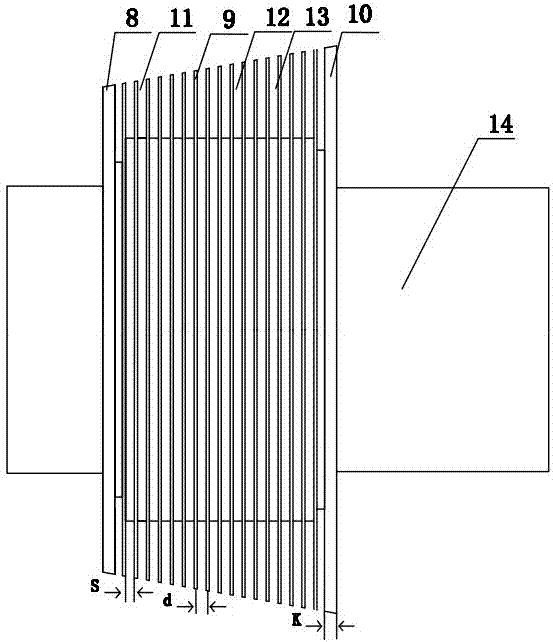

[0026] The processing process of the vibrating plate is as follows: image 3 shown.

[0027] A. Punching the original blank: the punching machine used for mechanical processing punches the original blank 1' of the double-piece conjoined vibrating piece that is connected together and has a through hole at one time, and the size of the original blank of the double-piece vibrating piece is according to the design requirements. make;

[0028] B. Groove milling: use a milling cutter to process two parallel grooves 2 according to the design requirements on the sides of the through holes on both sides of the original blank 1' of the two-piece conjoined vibration piece;

[0029] C. Triangular groove milling: On the original bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com