Nut welding technology

A welding process and welding tooling technology, applied in the field of nut welding process, can solve the problems of unstable welding state, large contact surface, poor welding quality, etc., and achieve the effects of good processing quality, small size deviation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

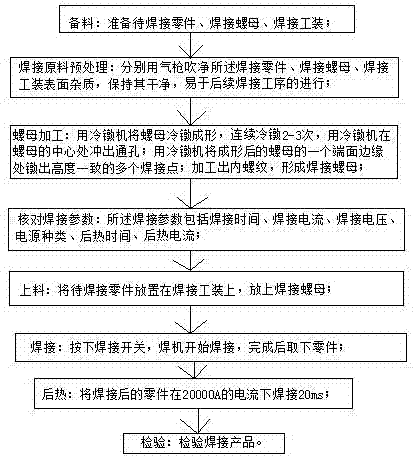

[0029] combine figure 1 , a nut welding process provided by the present embodiment, the nut welding process includes the following steps:

[0030] The first is to prepare materials: prepare the parts to be welded, welding nuts, and welding fixtures. The welding fixture is a set of flexible fixtures for welding fixation, compression, and positioning. In the material preparation process, the cross section of the lower electrode is reduced so that the extension of the cross section becomes a quadrilateral circumscribed circle formed by the four welding feet of the nut, and the length of the lower electrode is elongated at the same time;

[0031] Then pre-treat the welding raw materials: blow off the surface impurities of the welding parts, welding nuts and welding tooling with an air gun respectively, keep them clean, and facilitate the subsequent welding process;

[0032] Then process the nut: use a cold heading machine to cold-head the nut, and cold-head three times in a row t...

Embodiment 2

[0042] combine figure 1 , a nut welding process provided by the present embodiment, the nut welding process includes the following steps:

[0043] The first is to prepare materials: prepare the parts to be welded, welding nuts, and welding fixtures. The welding fixture is a set of flexible fixtures for welding fixation, compression, and positioning. In the material preparation process, the cross section of the lower electrode is reduced so that the extension of the cross section becomes a quadrilateral circumscribed circle formed by the four welding feet of the nut, and the length of the lower electrode is elongated at the same time;

[0044] Then pre-treat the welding raw materials: blow off the surface impurities of the welding parts, welding nuts and welding tooling with an air gun respectively, keep them clean, and facilitate the subsequent welding process;

[0045] Then process the nut: use a cold heading machine to cold-head the nut, and cold-head three times in a row t...

Embodiment 3

[0055] combine figure 1 , a nut welding process provided by the present embodiment, the nut welding process includes the following steps:

[0056] The first is to prepare materials: prepare the parts to be welded, welding nuts, and welding fixtures. The welding fixture is a set of flexible fixtures for welding fixation, compression, and positioning. In the material preparation process, the cross section of the lower electrode is reduced so that the extension of the cross section becomes a quadrilateral circumscribed circle formed by the four welding feet of the nut, and the length of the lower electrode is elongated at the same time;

[0057] Then pre-treat the welding raw materials: blow off the surface impurities of the welding parts, welding nuts and welding tooling with an air gun respectively, keep them clean, and facilitate the subsequent welding process;

[0058] Then process the nut: use a cold heading machine to cold heading the nut, and cold heading twice in a row to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com