Prefabricated prestress heat-preservation external wall board, special mold and manufacturing method of external wall board

A thermal insulation exterior wall and prestressing technology, applied in the field of building steel structures, can solve the problems of increasing the main force of the structure, unfavorable structural seismic design, affecting product quality, etc., to reduce self-weight, reduce wet work and environmental pollution, and increase thermal insulation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

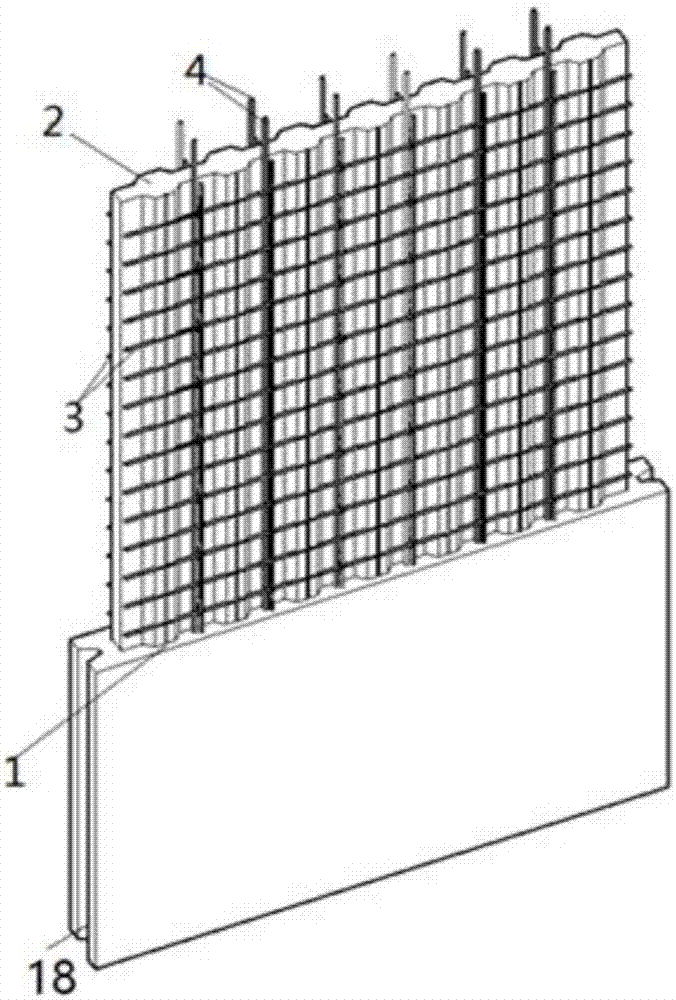

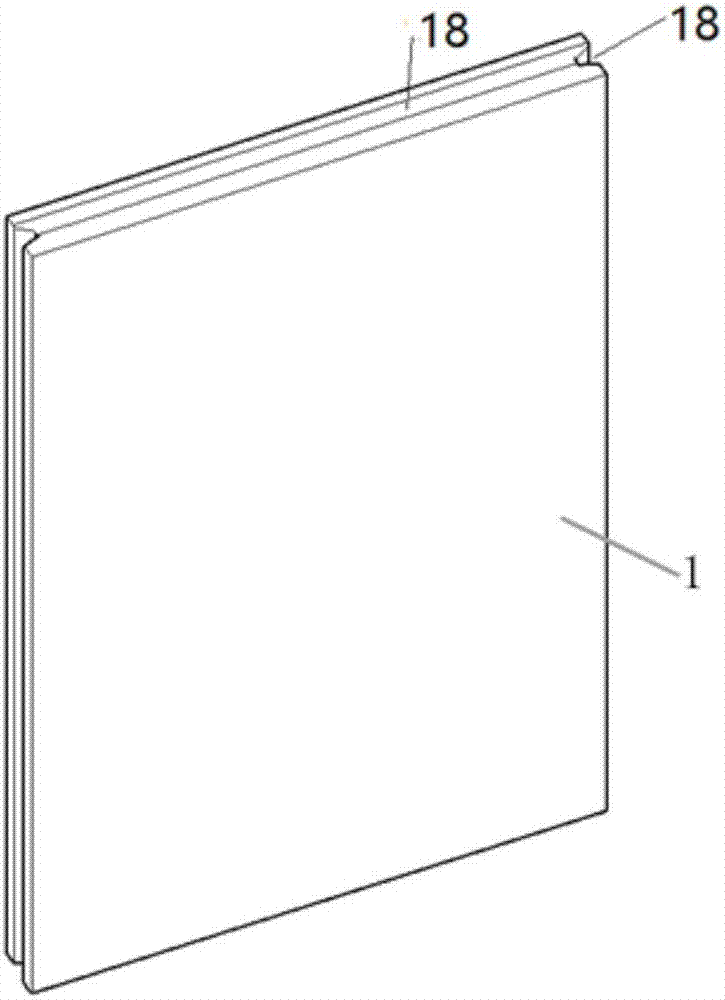

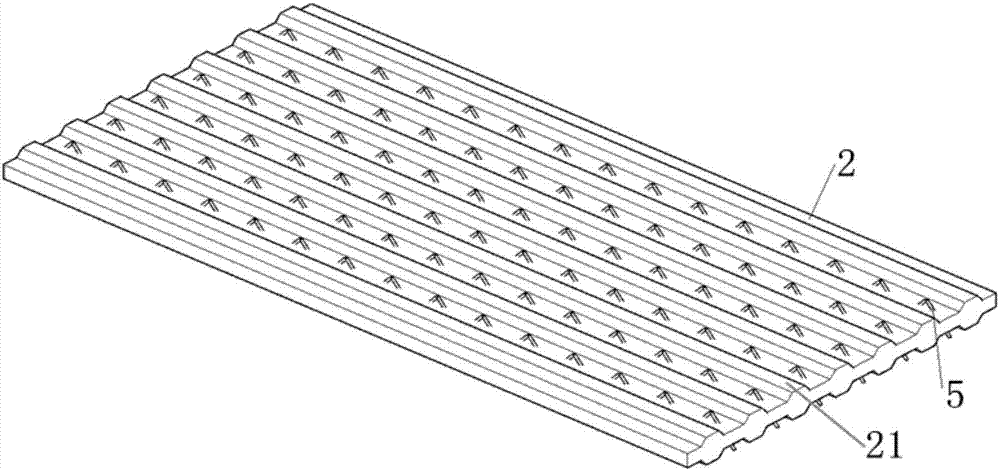

[0039] On the one hand, the present invention provides a prefabricated prestressed thermal insulation external wall panel, such as Figure 1 to Figure 5 As shown, it includes a thermal insulation core plate 2, a steel mesh 3 located on both sides of the thermal insulation core plate 2, and a concrete layer 1 poured on the steel mesh 3. A plurality of long thermal insulation core ribs 21 are provided on the thermal insulation core plate 2. The concrete layer 1 is provided with a plurality of concrete ribs that are staggered and matched with the insulation core ribs 21. The adjacent insulation core ribs 21 are interspersed with shear connectors 5 connected to the reinforcing steel mesh 3. Prestressed ribs 4 are arranged in the groove formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com