Electroless copper plating method on the surface of rigid pmi foam integrated waveguide

A technology of surface chemistry and integrated waveguide, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of poor bonding with plastic substrates, etc., and achieve strong bonding, high purity of plating, and electrical conductivity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

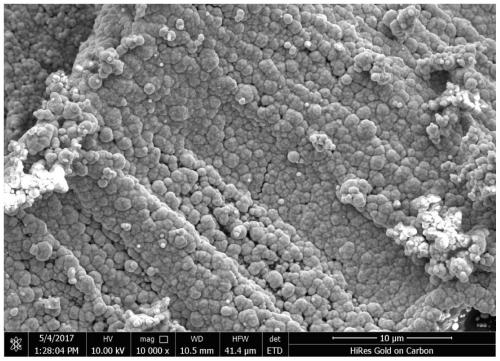

Image

Examples

Embodiment 1

[0021] The density of the good PMI rigid foam of processability selected by the present embodiment is 70Kg / m 3 .

[0022] Step 1, set the density to 70Kg / m 3 The advanced PMI foam is processed, engraved, polished, and the whole hole.

[0023] Step 2: Measure and weigh the size of the foam and soak it in absolute ethanol for 5 minutes, then wash it.

[0024] Step 3. Soak the cleaned foam in 1.8g / L sodium hydroxide and 1.8g / L anhydrous sodium carbonate aqueous solution for 5 minutes to roughen it, take it out, wash it, and then place it in a sulfuric acid aqueous solution with a concentration of 10ml / L for 10 minutes , take out and wash.

[0025] Step 4. Put the roughened foam into the activation solution for 1.5h activation. After palladium metal particles are attached to the surface, take out the degumming and wash it.

[0026] Step 5. Dissolve 2g of anhydrous copper sulfate, 3g of ethylenediaminetetraacetic acid, and 3g of potassium sodium tartrate in 200ml of deionized w...

Embodiment 2

[0031] The density of the good PMI rigid foam of processability selected by the present embodiment is 110Kg / m 3 .

[0032] Step 1. Set the density to 110Kg / m 3 The advanced PMI foam is processed, engraved, polished, and the whole hole.

[0033] Step 2: Measure and weigh the size of the foam and soak it in absolute ethanol for 5 minutes, then wash it.

[0034] Step 3. Soak the cleaned foam in 2.25g / L sodium hydroxide and 2.0g / L anhydrous sodium carbonate aqueous solution for 7 minutes to roughen, take it out, wash it, and then place it in a sulfuric acid aqueous solution with a concentration of 10ml / L for 10 minutes , take out and wash.

[0035] Step 4. Put the roughened foam into the activation solution for 1.5h activation. After palladium metal particles are attached to the surface, take out the degumming and wash it.

[0036] Step 5. Dissolve 2g of anhydrous copper sulfate, 3g of ethylenediaminetetraacetic acid, and 3g of potassium sodium tartrate in 200ml of deionized w...

Embodiment 3

[0041] The density of the good PMI rigid foam of processability selected in this embodiment is 200Kg / m 3 .

[0042] Step 1. Set the density to 200Kg / m 3 The advanced PMI foam is processed, engraved, polished, and the whole hole.

[0043] Step 2. Foam surface cleaning: Measure the size of the foam, weigh it, soak it in absolute ethanol, soak it for 5 minutes, and wash it.

[0044] Step 3. Soak the cleaned foam in 2.5g / L sodium hydroxide and 2.5g / L anhydrous sodium carbonate aqueous solution for 10 minutes to roughen, take it out, wash it, and then place it in a concentration of 10ml / L sulfuric acid aqueous solution for 10 minutes. Take it out and wash it.

[0045] Step 4. Put the roughened foam into the activation solution for 1 hour activation. After palladium metal particles are attached to the surface, take out the degumming and wash it.

[0046] Step 5. Dissolve 8g of anhydrous copper sulfate, 12g of ethylenediaminetetraacetic acid, and 12g of potassium sodium tartrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap