Underground structure outer wall superposed wall adopting HCMW construction method and construction method thereof

A technology of underground structure and construction method, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., and can solve the difficulty of external wall formwork construction, external wall vertical formwork construction, and the difficulty of compacting and compacting fertilizer tank backfill soil, etc. Improve the construction environment, reduce the number of construction joints, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment is suitable for the waterproof level requirements of level two and below, as follows:

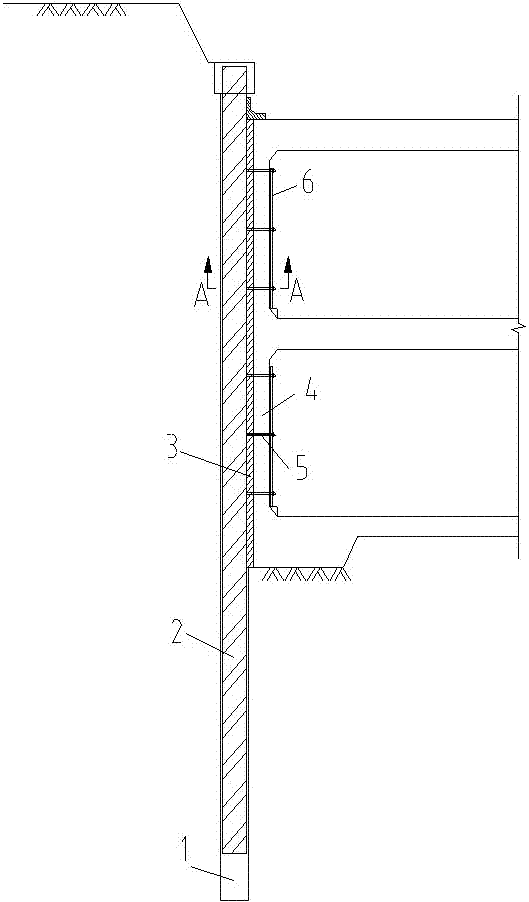

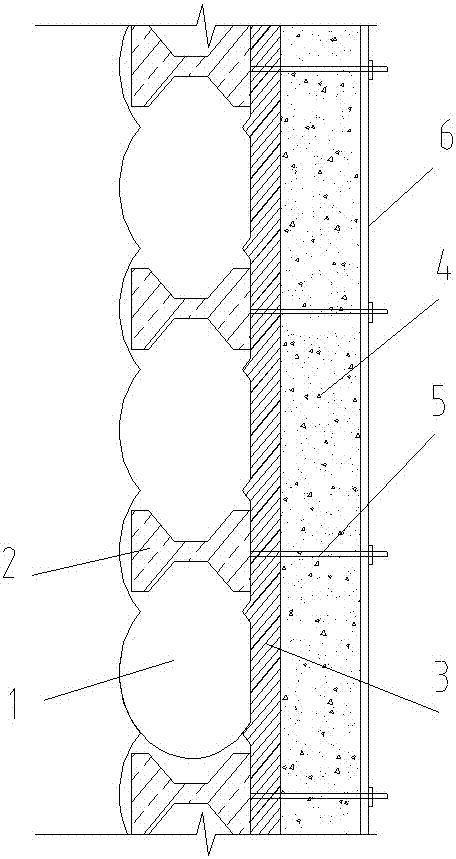

[0061] A laminated wall of an exterior wall of an underground structure with HCMW method, comprising:

[0062] A cement-soil mixing pile wall, the cement-soil mixing pile wall includes a plurality of cement-soil mixing piles 1 that continuously interlock with each other, and reinforced concrete prefabricated piles 2 are inserted at intervals or continuously in the plurality of cement-soil mixing piles;

[0063] The leveling layer 3 is arranged on the inner wall of the cement-soil mixing pile wall;

[0064] An exterior wall of the underground structure 4, the exterior wall of the underground structure is arranged on the inner wall of the leveling layer, and the exterior wall of the underground structure includes steel bars and concrete mixed with a waterproof compacting agent;

[0065] The cement-soil mixing pile wall and the exterior wall of the underground structure...

Embodiment 2

[0078] This embodiment is suitable for the first-level waterproof level requirements, as follows:

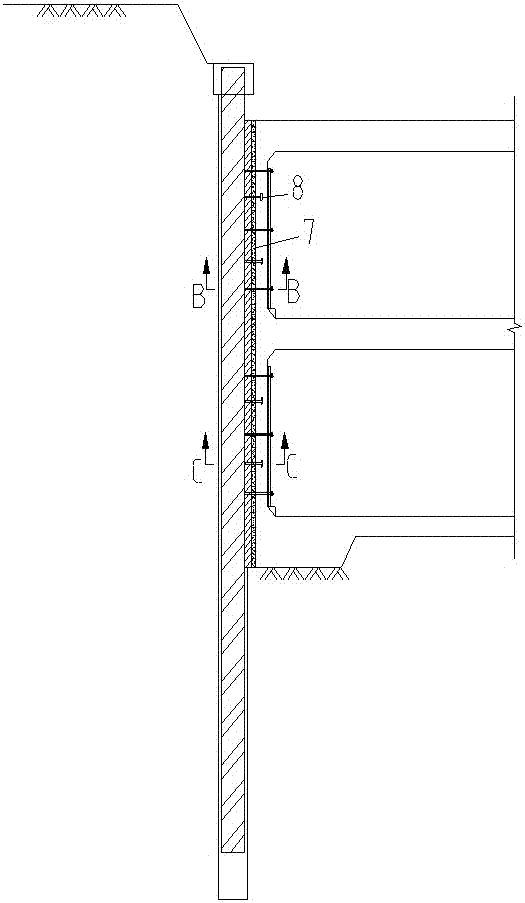

[0079] A laminated wall of an exterior wall of an underground structure with HCMW method, comprising:

[0080] A cement-soil mixing pile wall, the cement-soil mixing pile wall includes a plurality of cement-soil mixing piles that continuously interlock with each other, and reinforced concrete prefabricated piles are inserted at intervals or continuously in the plurality of cement-soil mixing piles;

[0081] The leveling layer is set on the inner wall of the cement-soil mixing pile wall;

[0082] waterproof mortar layer 7, the waterproof mortar layer is arranged on the inner wall of the leveling layer;

[0083] The external wall of the underground structure, the external wall of the underground structure is arranged on the inner wall of the waterproof mortar layer, and the external wall of the underground structure includes steel bars and concrete mixed with a waterproof compact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com