Combined type rubber metal joint bearing and method

A kind of joint bearing, rubber metal technology, applied in the direction of bearings, flexible bearings, bearing components, etc., can solve the problem that joint bearings are difficult to achieve deflection buffering and large bearing capacity at the same time, difficult to meet rail vehicles and other problems, to reduce vibration and noise, Effect of increasing radial load carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

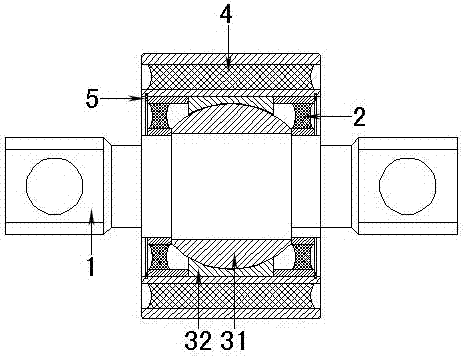

[0038] Such as figure 1 As shown, the mandrel 1 is embedded in the joint inner ring 31 , and the outer periphery of the joint inner ring 31 is covered with the joint outer ring 32 . In the metal joint bearing in this embodiment, on the original structure, a rubber bushing 4 is added to improve the radial bearing capacity and radial cushioning performance; a rubber stopper is added between the rubber bushing 4 and the mandrel 1 The ring 2 is used to reduce the vibration and noise when the mandrel 1 deflects, and a snap spring 5 is provided outside the rubber retaining ring 2 to prevent the rubber retaining ring 2 from slipping out.

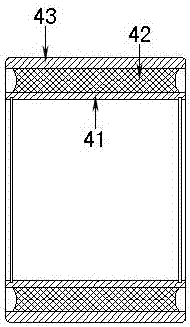

[0039] Such as figure 2 As shown, the rubber bushing 4 is vulcanized into a whole by an inner sleeve 41, a bushing rubber layer 42 and an outer jacket 43, and the bushing rubber layer 42 is an elastic component. In order to prevent stress concentration when the bushing rubber layer 42 is squeezed, both sides of the bushing rubber layer 42 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com