A kind of reinforcement method of ccga device

A device and PCB board technology, applied in the field of CCGA device reinforcement, can solve the problems of inability to meet product application environment requirements, solder joint cracking, low cost, etc., and achieve the effect of solving the problem of solder joint cracking failure, reliable electrical connection, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] The verification conditions are formulated according to ECSS-Q-ST-70-08C The manual soldering of high-reliability electrical connections ECSS-Q-ST-70-38C and high-reliability soldering for surface-mount and mixed technology.

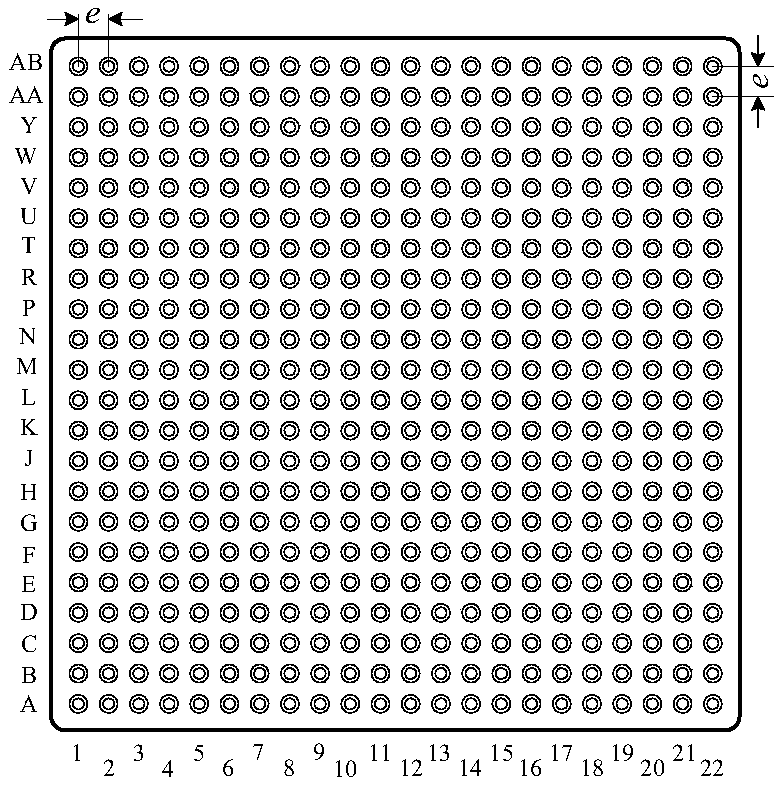

[0038] Table 1 LCDSP0102 device CCGA484 package size table

[0039]

[0040] see image 3 , make test printed circuit board, CCGA device is installed on the printed circuit board and strengthened by the method of the present invention, made a group of samples reinforced with epoxy glue and carried out comparative test simultaneously, test according to such as Figure 4 The test procedure shown and the test conditions shown in Table 2 were carried out.

[0041] Table 2 Test verification conditions

[0042]

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com