Power transmission line recessed assembled cable trench and laying method thereof

A technology for power transmission lines and cable trenches, which is applied in the direction of cable installation, ground cable installation, and cable laying equipment. Structural waterproof requirements, expanding the scope of application, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Best practice:

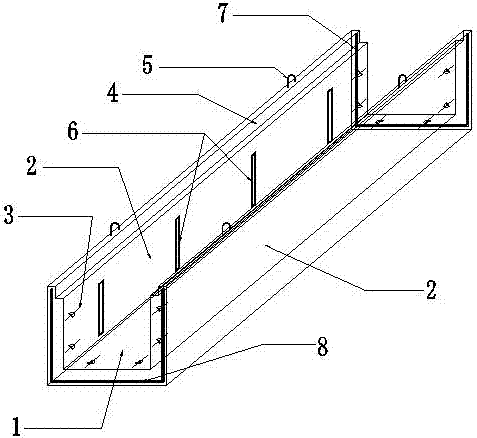

[0032] Refer to attached figure 1 , a concave assembled cable trench for power transmission lines, which is composed of a plurality of joints connected from end to end in sequence. The cross-section of each joint is concave, including the bottom plate 1 and two side plates 2; the longitudinal direction of each joint is 3.0~6.0 In section m, the overall weight of a single prefabricated component is controlled within 20t and prefabricated in the factory, and can be constructed with small hoisting machinery.

[0033] The inner surface of the side plate 2 of each trench body is pre-embedded with grooved cable bracket embedded parts 6 at a distance of 1.0~1.25m along the longitudinal direction, which are used to install the grooved cable bracket. The embedded parts and the connecting parts connected to the outside can meet the installation requirements of the subsequent grounding system, and through the groove connection, the welding engineering amount of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com