Insulation structure of winding rotor coil

A technology of insulation structure and wound rotor, applied in the shape/style/structure of winding insulation, etc., can solve the problem that F-class insulation cannot meet the actual use requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

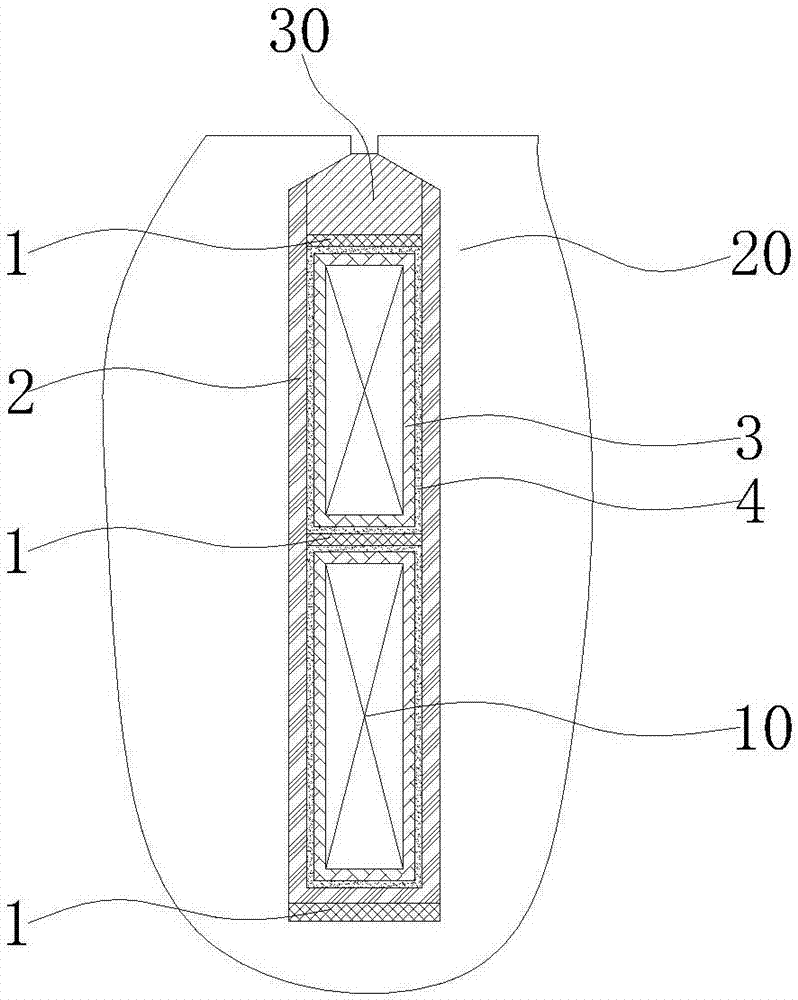

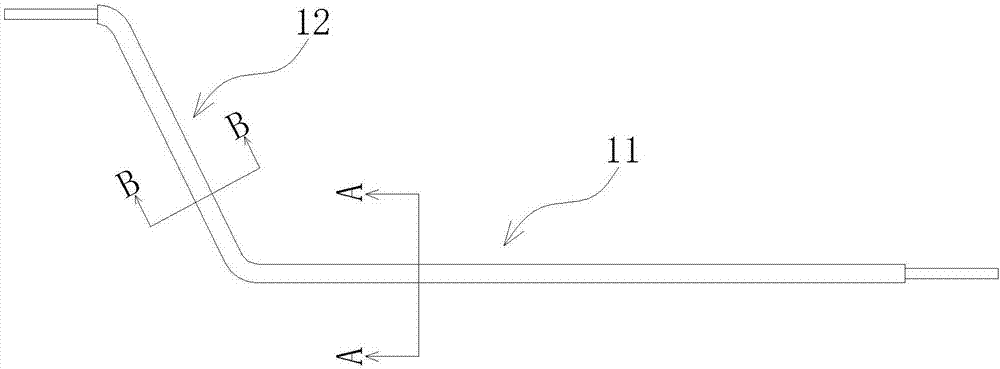

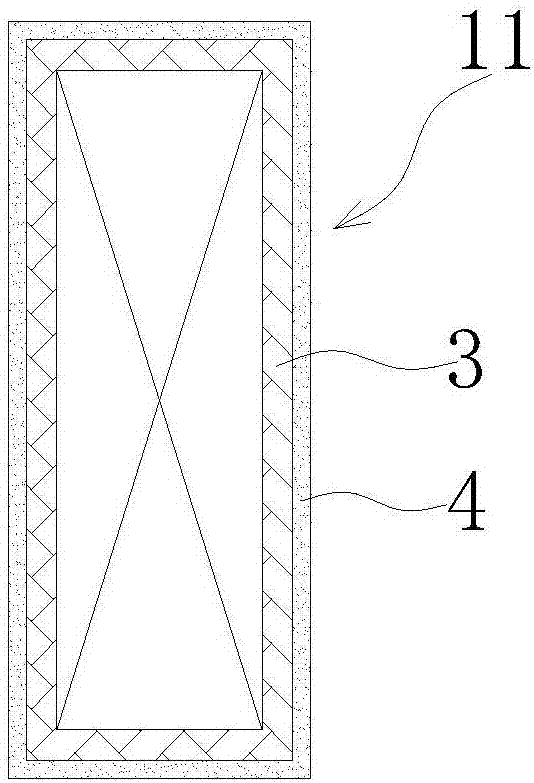

[0010] combined with Figures 1 to 4 The present invention is further described:

[0011] An insulating structure for a wound rotor coil, comprising a flat copper coil 10, the flat copper coil includes an inter-slot segment 11 and an outer-slot segment 12, and the inter-slot segment 11 is covered with silicone powder mica tapes 3, The heat-shrinkable polyester film tape 4, the outer section 12 of the groove is covered with a polyimide film tape 5, an organic silicon powder mica tape 3, and an alkali-free glass ribbon 6 from the inside to the outside. The silicone powder mica tape 3 has good flexibility, high electrical, electrothermal and mechanical properties, and is used as the first layer of the inter-slot section 11 and the second layer of the outer-slot section 12 to form a continuous coating , to ensure that there is no gap between the slot section 11 and the slot outer section 12, even if it is bent, there will be no leakage; It is a heat-shrinkable packaging material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com