Gas-liquid separation device in nozzle button type

A gas-liquid separation device and hood type technology, which is applied in the field of hood type gas-liquid separation device and wet flue gas desulfurization equipment, can solve the problem of reducing the solid content and pH value of the slurry, increasing the consumption of absorbent and reducing the secondary Circulating desulfurization efficiency and other issues, to achieve the effect of improving desulfurization efficiency, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

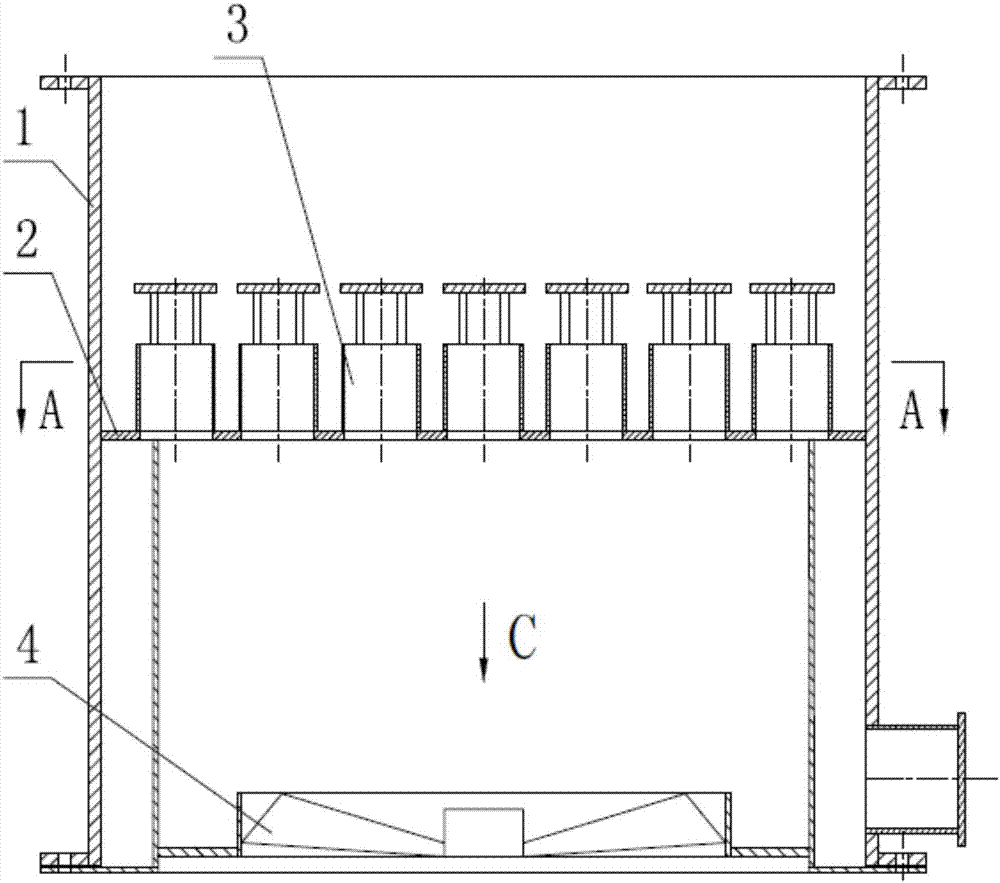

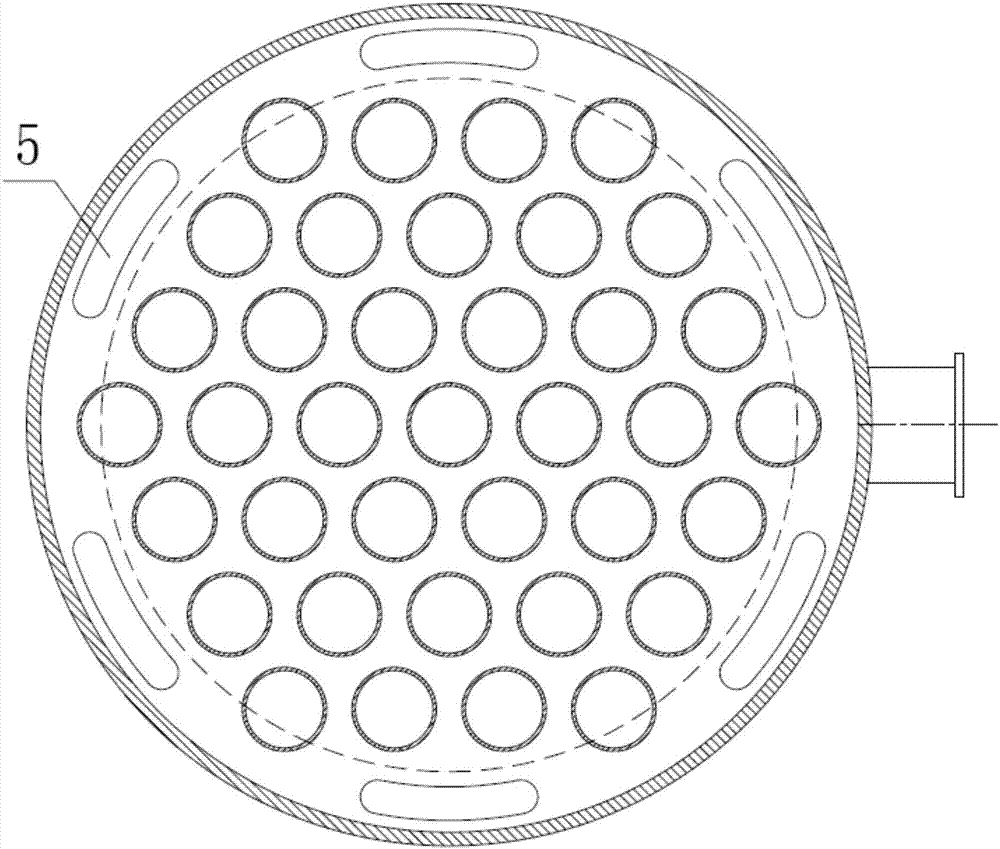

[0029] Such as Figure 1 to Figure 3 As shown, in one embodiment, a hood-type gas-liquid separation device is provided, including: a channel 1 and a partition 2, the partition 2 divides the channel 1 into an upper channel and a lower channel; the middle area of the partition 2 is opened A number of flow holes; a number of slurry collection holes 5 are opened in the area other than the middle area of the separator 2; preferably, the area of the middle area is 50% to 85% of the overall plane area of the separator.

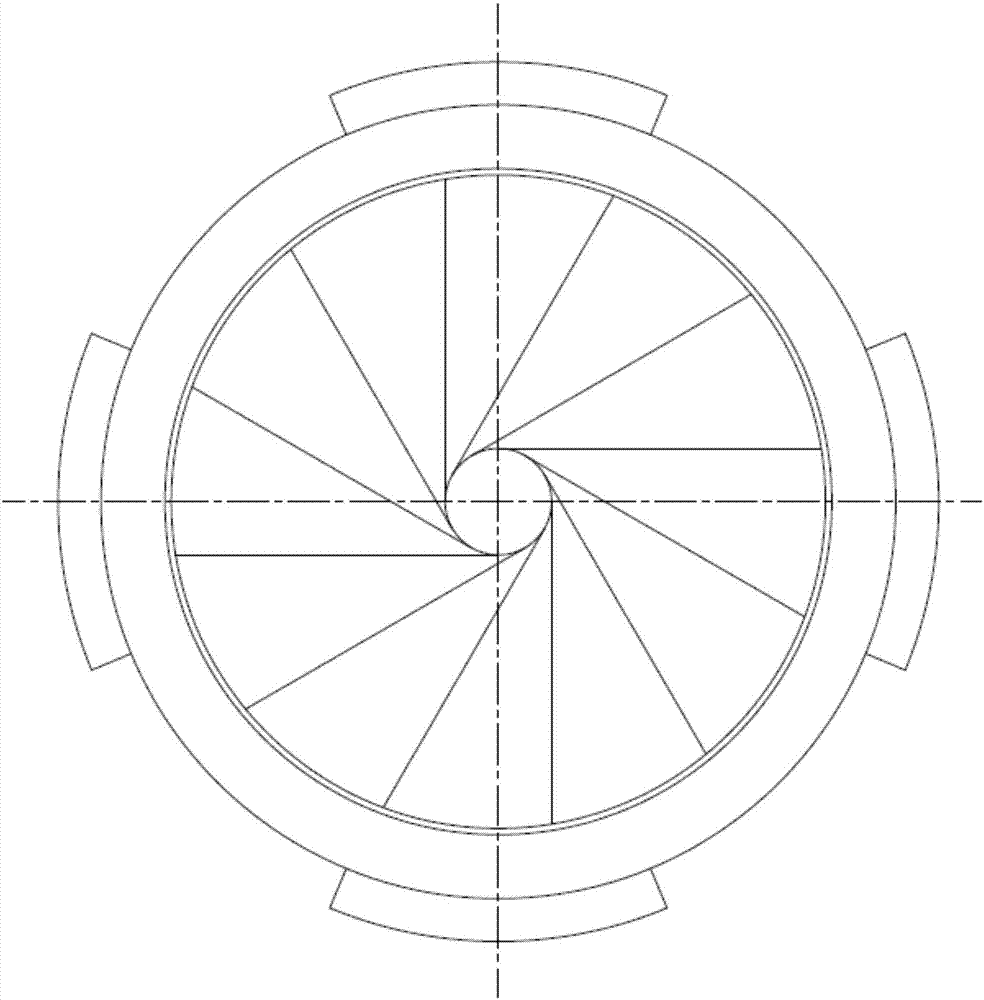

[0030] Several wind caps 3 covering the flow holes; the wind caps 3 have uniformly distributed lateral openings; as figure 2 , the hoods are evenly distributed in an array. In another embodiment, the air caps may also be evenly distributed in concentric circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com