Feeding and stirring bidirectional executed stirring machine for cattle feed

A cattle feed and mixer technology, which is applied to mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems of uneven feeding, inhomogeneous intake, and insufficient intake, and achieves improved quality and improved Meat yield, increase the effect of mixing and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

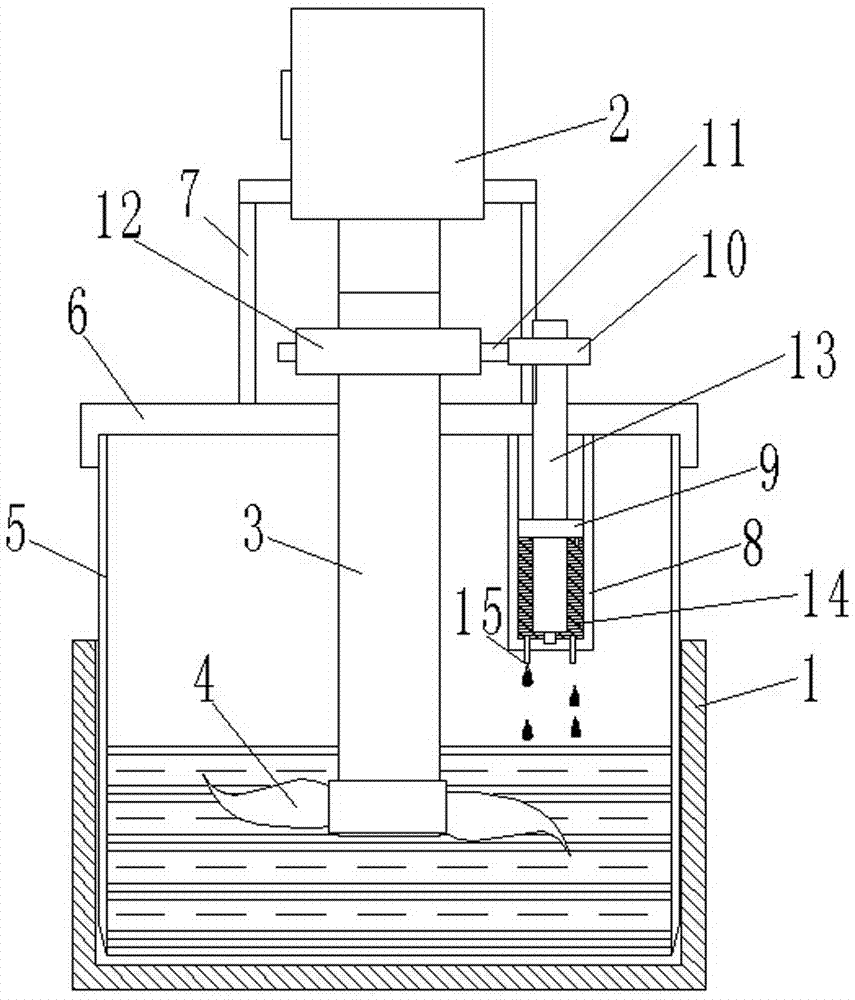

[0008] figure 1 , 2 Middle: Bottom barrel 1, motor 2, stirring shaft 3, stirring double blades 4, socket barrel 5, upper cover 6, connector 7, storage barrel 8, piston 9, worm wheel 10, worm 11, intersecting shaft transmission mechanism 12 , threaded rod 13, material cavity 14, discharge nozzle 15.

[0009] A two-way mixer for feeding and stirring cattle feed. The two-way mixer for feeding and stirring cattle feed includes a bottom bucket 1, a stirring assembly, and an automatic feeding assembly installed on the mixing assembly. The bottom bucket 1 is used to hold cattle The feed can be directly placed in the cowshed to directly provide the food in the bottom bucket for the cattle to eat. The stirring assembly includes a motor 2, a stirring shaft 3, a stirring double blade 4, an insertion barrel 5, and an upper cover 6. The motor shaft of the motor 2 is fixedly connected to the upper end of the stirring shaft 3. In this embodiment, a welding connection is adopted. The stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com