Overlay Welding Repair Technology of Large 70cr3mo Backup Roll

A back-up roll, large-scale technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of difficult repair technology and high failure risk, back-up roll failure and scrapping, etc., to reduce the workload of surfacing welding, reduce cooling speed, Effect of Reducing Hardening Tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

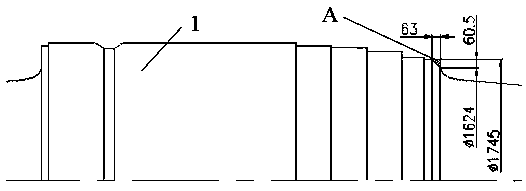

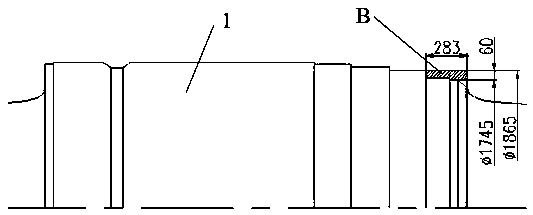

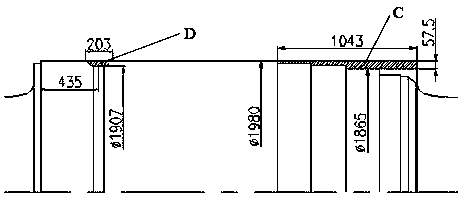

[0025] The surfacing repair process of large 70Cr3Mo back-up rolls forms a large-thick surfacing repair layer after surfacing, and the surfacing repair layer follows the radial direction of the end face of the back-up roll from inside to outside in order of two layers of primer, two transition layers and several layers of work. Among them, flux I and flux II are both HJ260, and flux III is HJ107; the primer layer is formed by welding wire I and flux I to the surface of the back-up roller body, and the alloy composition of welding wire I is composed of the following elements by weight percentage: C 0.01~0.03%, Si 0.40~0.80%, Mn1.00~2.20%, Cr 0.70~1.50%, Ni 0.50~1.20%, Mo 0.40~1.00%, S≤0.025%, P≤0.03%, the balance i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com