Plastic product for removing VOC and odor by using photocatalyst and preparation method thereof

A technology for plastic products and photocatalysts, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of poor photocatalytic effect, difficulty in achieving selective dispersion, etc., to achieve photocatalytic degradation of VOC, promotion, and increase of photocatalyst content. , the effect of avoiding shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

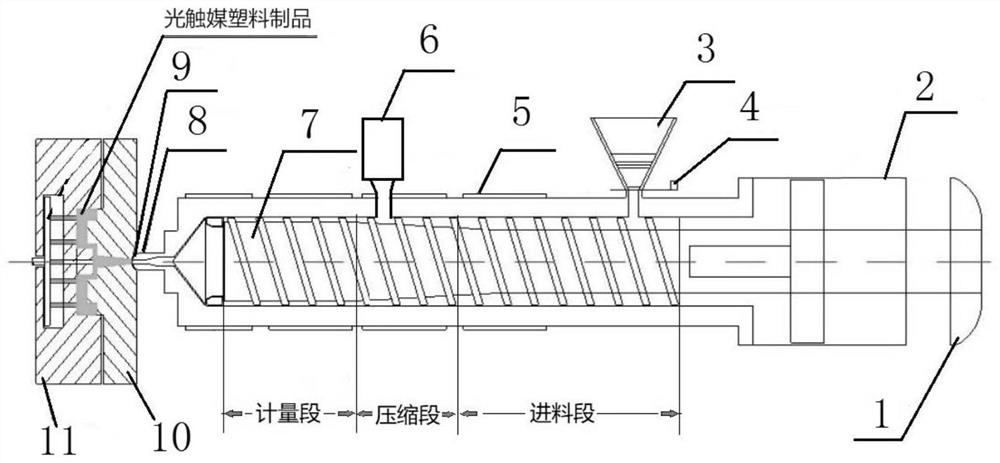

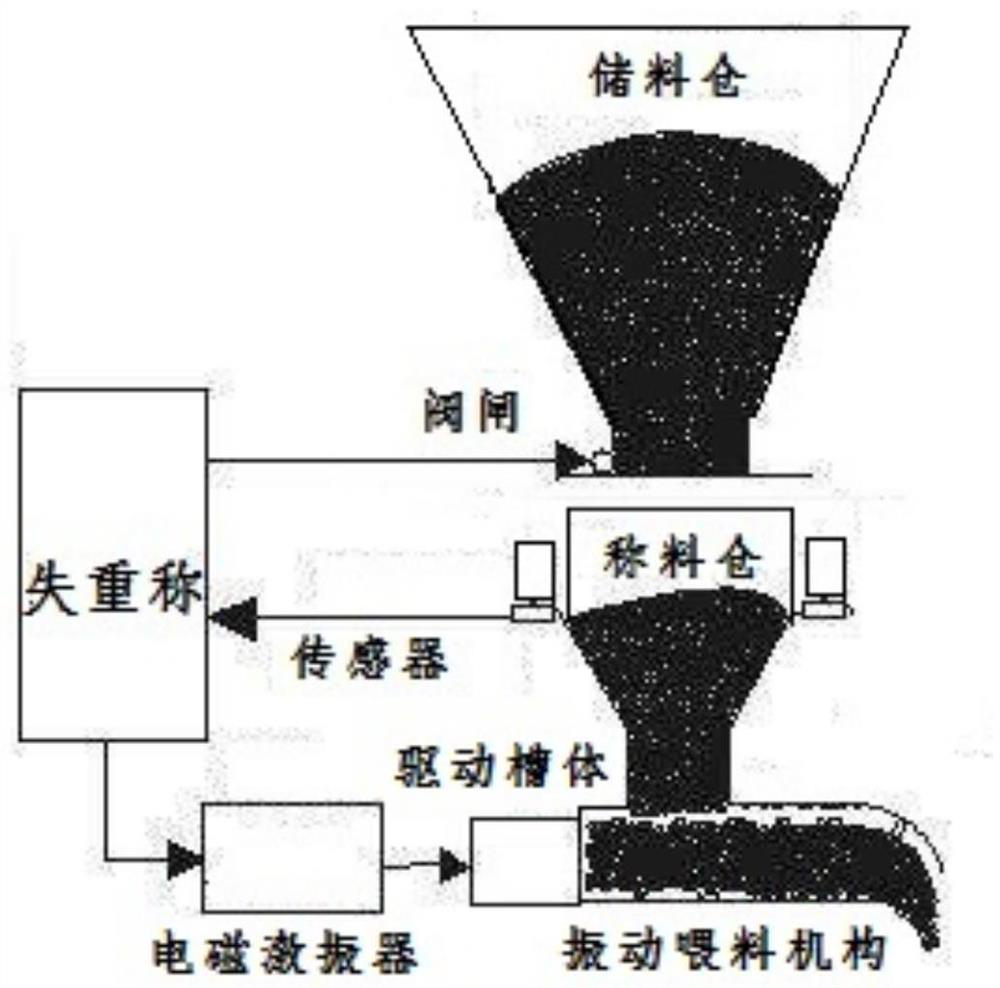

[0028] Embodiment 1, prepare the injection molding machine that adopts photocatalyst to remove the plastic product of VOC and odor, as figure 1 , figure 2 and image 3As shown, it includes a motor 1, an oil cylinder 2, a machine barrel and a mould, which are connected to each other. A screw 7 cooperating with the machine barrel is installed in the machine barrel, and a heating ring 5 is wound outside the machine barrel to facilitate heating and melting of materials in the machine barrel. The cylinder is composed of a feeding section, a compression section and a metering section; the front end of the feeding section is provided with a hopper 3 for matrix resin feeding, the lower part of the hopper 3 is detachable, and a feeding drawer 4 is installed to facilitate the opening and closing of the material feeding step, and the end of the compression section is set The photocatalyst feeding device 6 that is convenient for photocatalyst feeding, the end of the metering section is ...

Embodiment 2

[0033] Embodiment 2, a kind of preparation method that adopts photocatalyst to remove VOC and the plastic product of odor, comprises the following steps:

[0034] A. Prepare raw materials by weight, namely ABS matrix resin: 98 parts, activated carbon as carrier TiO 2 Photocatalyst: 2 parts;

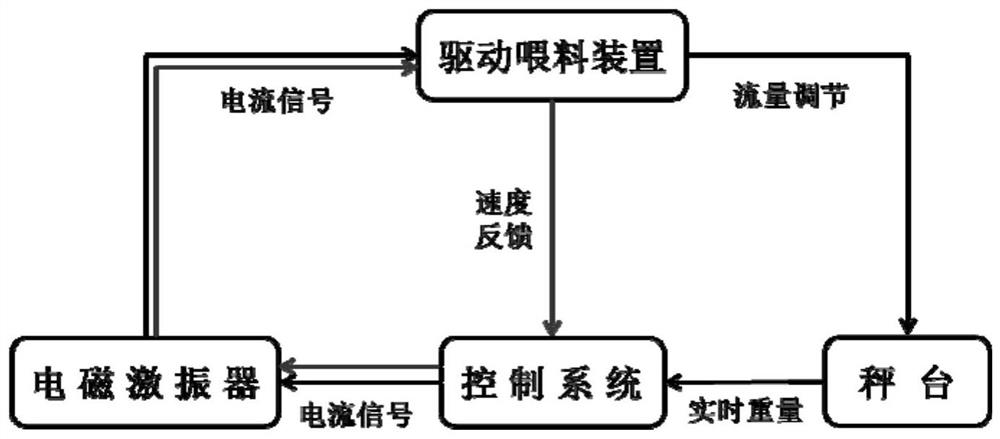

[0035] B. Add the ABS matrix resin into the injection molding machine through the hopper, and the matrix resin first passes through the feeding section of the barrel through the screw, and the temperature of the feeding section of the barrel is 210°C; then enters the compression section (melting section) of the barrel for processing Heating, shear melting, the temperature of the compression section is 210 ° C, at the end of the compression section, activated carbon as the carrier of TiO 2 photocatalyst through figure 2 The shown photocatalyst feeding device enters; the speed of photocatalyst addition is passed as image 3 Control system settings shown.

[0036] C. After the ABS matri...

Embodiment 3

[0037] Embodiment 3, a kind of preparation method that adopts photocatalyst to remove VOC and the plastic product of odor, comprises the following steps:

[0038] A. Prepare raw materials by weight, namely ABS matrix resin: 95 parts, activated carbon as carrier TiO 2 Photocatalyst: 5 parts;

[0039] B. Add the ABS matrix resin into the injection molding machine through the hopper, and the matrix resin first passes through the feeding section of the barrel through the screw, and the temperature of the feeding section of the barrel is 200°C; then enters the compression section (melting section) of the barrel for processing Heating, shearing and melting, the temperature of the compression section is 220°C, at the end of the compression section, the photocatalyst enters through the photocatalyst feeding device; the speed of photocatalyst addition is set by the control system.

[0040] C. After the ABS matrix resin is fully melted, it enters the metering section together with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com