Oil tank for unmanned aerial vehicle

A drone and fuel tank technology, applied in the aerospace field, can solve the problems that the split fuel tank cannot take into account weight and sealing, restrict the use and maintenance of drones, and detect the location of leaks, etc. Excellent effect, short duration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

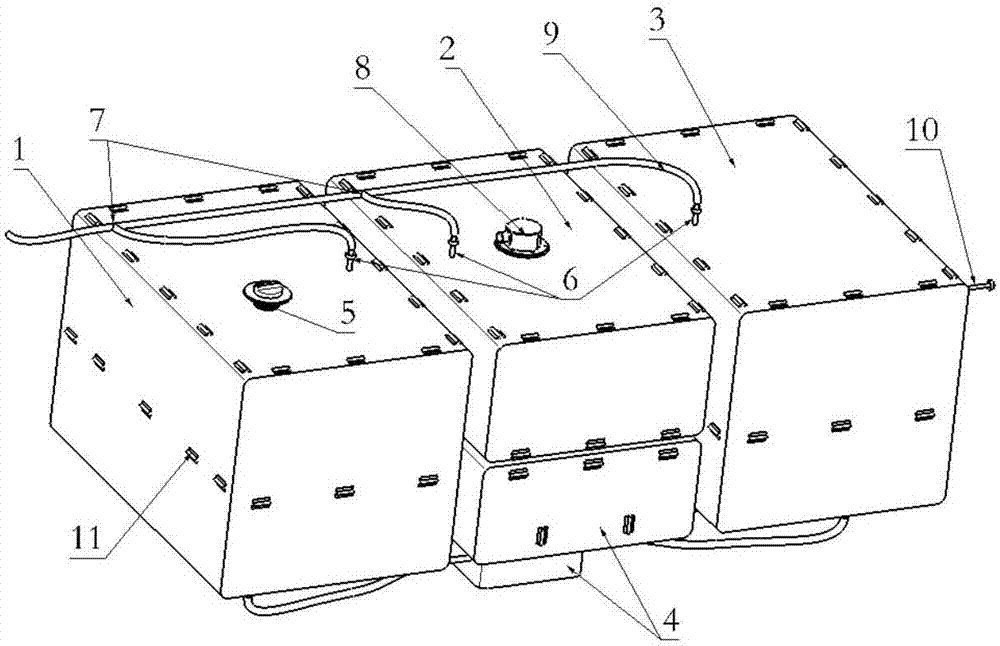

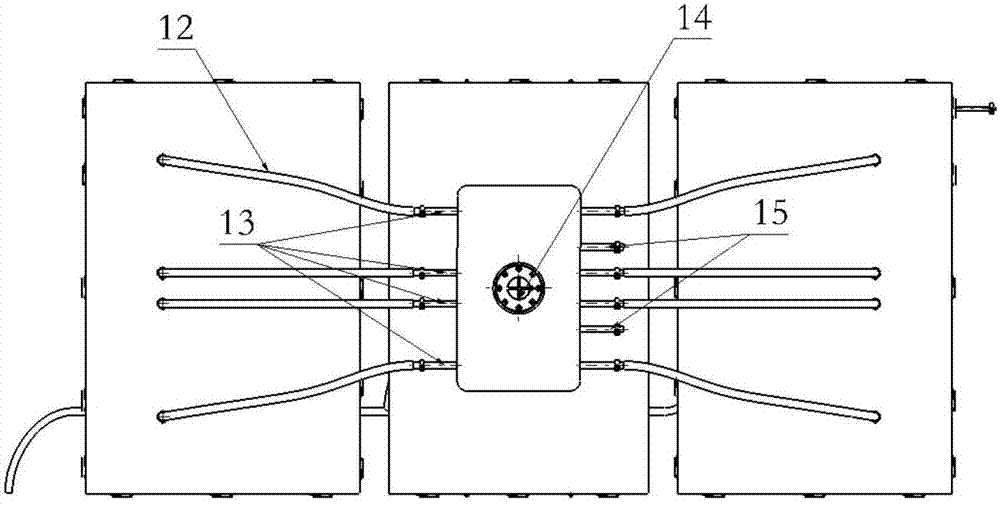

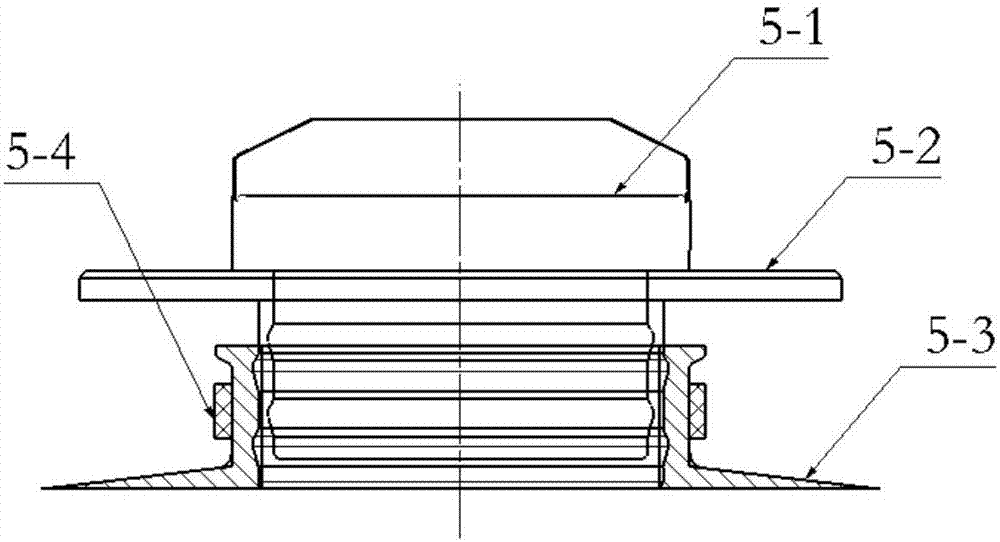

[0040] Please refer to the attached picture, a kind of fuel tank for unmanned aerial vehicles, combined with figure 1 and figure 2 As shown, it consists of 1# fuel tank shell 1, 2# fuel tank shell 2, 3# fuel tank shell 3, 4# fuel tank shell 4, oil filling port 5, air vent 6, tee adapter 7, oil quantity measurement Port 8, vent pipe 9, oil return port 10, lifting lug 11, oil delivery pipe 12, oil delivery port 13, oil discharge port 14 and oil supply port 15 constitute. The oil filling port 5 is located on the upper left part of the fuel tank, and is integrally formed with the 1# fuel tank shell 1, and oil gun or oil pipe can be used to refuel. #Fuel tank shell 3 is integrally formed, and communicates with the atmosphere through the tee adapter 7 and the vent pipe 9; the oil delivery port 13 is located at the bottom of the fuel tank, and is integrally formed with the respective connected fuel tank shells, and communicates with each fuel tank shell through the oil delivery pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com