Hydrolytic acidification reactor for sewage plant in industrial zone

A technology of hydrolysis and acidification, industrial park, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor water quality and quantity fluctuation, poor biodegradability of wastewater, etc., to achieve uniform water quality The effect of reducing water volume, reducing infrastructure costs and reducing biogas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

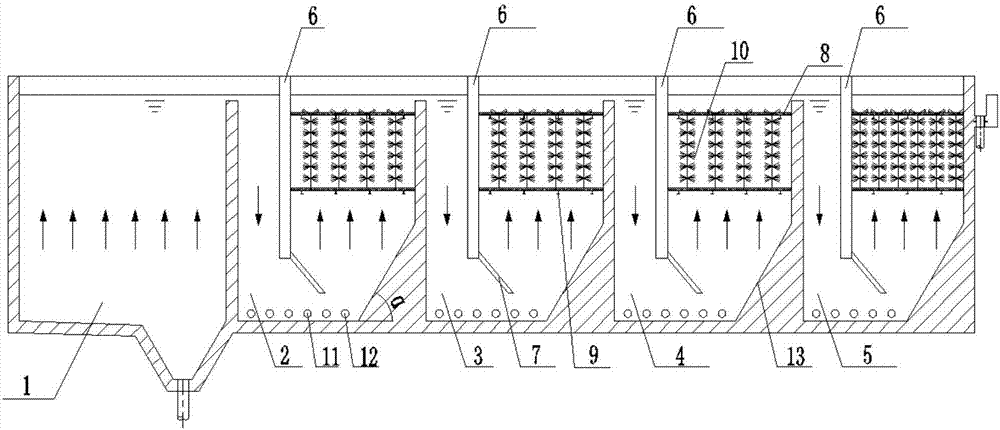

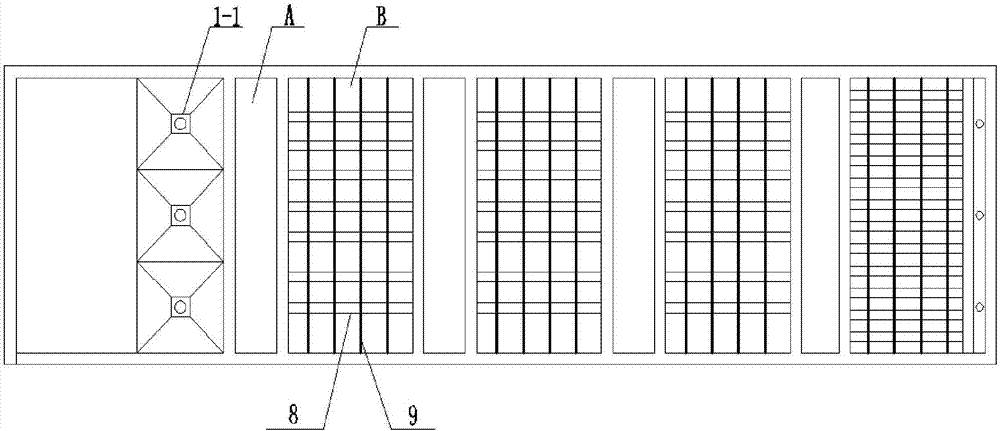

[0015] Specific Embodiment 1: The hydrolytic acidification reactor of the industrial park sewage plant in this embodiment includes a reactor, 5 cells, 4 baffles 6, elastic packing 10, threaded steel 8, support 9, sludge discharge pipe 11 and The aeration pipe 12 is divided into 5 compartments in the reactor by a partition wall, and along the flow direction of the sewage are the first compartment 1, the second compartment 2, the third compartment 3, and the fourth compartment 4 And the fifth compartment 5, a sludge hopper 1-1 is arranged at the bottom of the first compartment 1, vertically in the second compartment 2, the third compartment 3, the fourth compartment 4 and the fifth compartment 5 A baffle plate 6 is arranged directly, and a deflector 7 is arranged on the lower part of the baffle plate 6, and the second compartment 2 is divided into a downflow area A and an upflow area B by the baffle plate 6, and the baffle plate A water flow channel is formed between the plate 6...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that the sludge hopper 1-1 is connected to the sludge discharge pipe.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the angle between the baffle plate 6 and the deflector 7 is 140°, and the deflector 7 is inclined toward the upwelling area B.

[0019] In this embodiment, the water flow channel is narrowed by the deflector, the water flow is accelerated, and the mixing is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com