Water-based alkyd resin and preparation method thereof

A water-based alkyd resin, acid value technology, applied in the field of water-based alkyd resin and its preparation, can solve the problem that the wet adhesion of the alkyd resin needs to be further improved, and achieve the effects of improving water resistance and reducing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

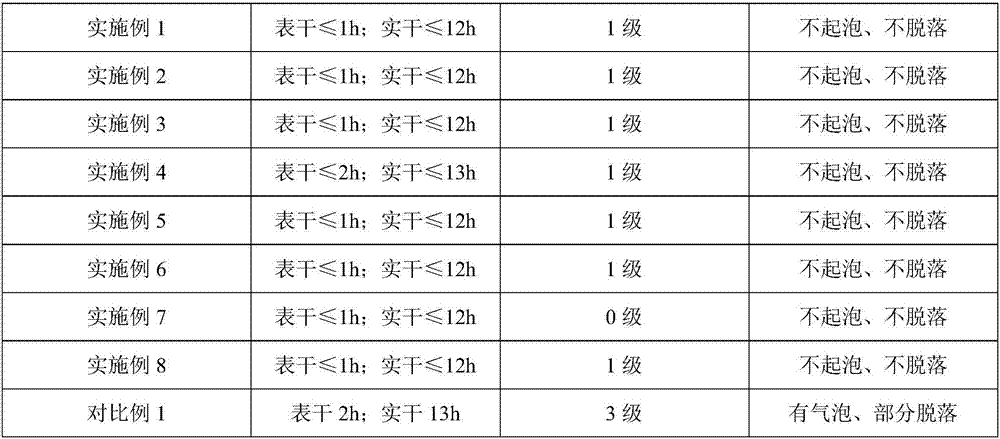

Examples

Embodiment 1

[0029] A preparation method of water-based alkyd resin, comprising the following steps:

[0030] S1. Add 40 parts by mass of linoleic acid, 5 parts by mass of benzoic acid, 11 parts by mass of dibasic acid, 9 parts by mass of polyhydric alcohol, and 1 part by mass of xylene into the reaction kettle, stir and heat up to 160-180°C , react for 3-4 hours, then heat up to 200-210°C, react for 5-6 hours, when the acid value of the reactant reaches 7mgKOH / g, enter step S2;

[0031] S2. First cool down to 160-170°C, then add 3 parts by mass of trimellitic anhydride and 1 part by mass of xylene, then raise the temperature to 175-185°C, react for 1-2 hours, when the acid value of the reactant reaches 35mgKOH / g , enter step S3;

[0032] S3. First cool down to 140°C, then add 5 parts by mass of sodium diisooctyl succinate, keep warm for 20min to 50min, and then enter step S4;

[0033] S4. Add 25 parts by mass of co-solvent, then lower the temperature to 100-120° C., stir evenly, and obt...

Embodiment 2

[0037] Its preparation method refers to Example 1, and the difference between Example 2 and Example 1 is that: 50 parts by mass of linolenic acid, 6 parts by mass of benzoic acid, 13 parts by mass of dibasic acid, 12 parts by mass of The xylene of polyhydric alcohol, 2 mass parts; Add the xylene of 4 mass parts of trimellitic anhydride and 2 mass parts in step S2; In step S3, add the diisooctyl sodium succinate sulfonate of 8 mass parts; Add 30 in step S4 Parts by mass of co-solvent.

Embodiment 3

[0039] Its preparation method refers to Example 1, and the difference between Example 5 and Example 1 is that: 50 parts by mass of linolenic acid, 6 parts by mass of benzoic acid, 13 parts by mass of dibasic acid, 12 parts by mass of The xylene of 2 mass parts of polyhydric alcohol; Add 4 mass parts of trimellitic anhydride and the xylene of 3 mass parts in step S2; In step S3, add the diisooctyl sodium succinate sulfonate of 8 mass parts; Add 30 mass parts in step S4 parts of co-solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com