Surface organic modification clay ore reinforcing filler and application thereof

A technology of clay minerals and reinforcing fillers, applied in the field of reinforcing fillers, can solve problems such as time-consuming, lack of economic feasibility, complex process, etc., and achieve the effects of reducing energy consumption, saving costs, and reducing intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

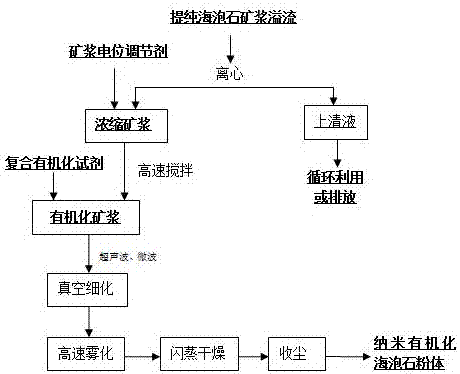

Method used

Image

Examples

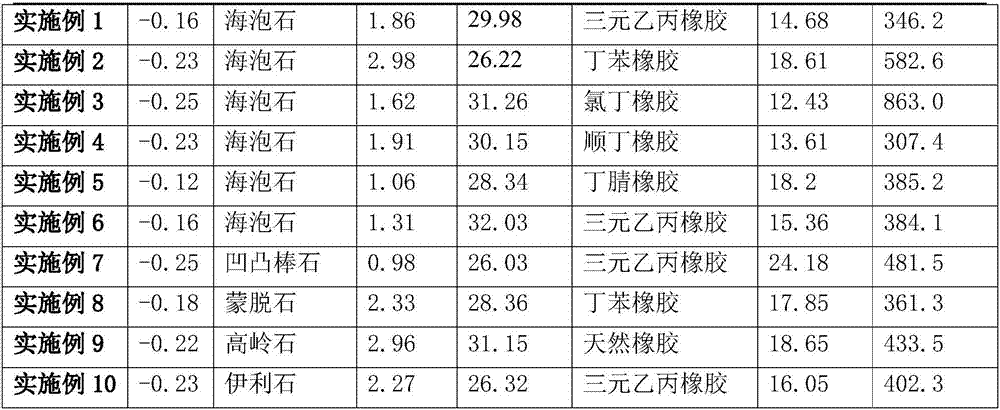

Embodiment 1

[0039] 1 kg of sepiolite ore powder with D50 less than 10 μm (D50 less than 10 μm is: the diameter of 50% of the particles in the powder sample is less than 10 μm, and D50 is also called the median particle size.) was added to 15 L of water at a stirring speed of 500 rpm. Stir for 30 minutes, stop stirring to form a uniform dispersed slurry. After 12 hours of natural settlement, the siphon method was used to suck out the suspended slurry in the upper layer. Put it into a centrifuge tank, centrifuge for 5 minutes at a centrifuge speed of 1500 rpm, pour out and combine the suspended pulp in the upper layer, and obtain purified pulp. Then clean the centrifuge tank after removing the sediment, pour the purified ore slurry into the centrifuge again, set the centrifuge speed to 4500rpm, centrifuge for 5min, pour out the supernatant, scrape out the thick mud at the bottom and stir evenly to obtain Get the concentrated pulp of sepiolite after purification, the density of this pulp is...

Embodiment 2

[0045] Add 1 kg of sepiolite ore powder with D50 less than 10 μm into 15 L of water at a stirring speed of 500 rpm, stir for 30 minutes, stop stirring to form a uniformly dispersed slurry. After 12 hours of natural settlement, the siphon method was used to suck out the suspended slurry in the upper layer. Put it into a centrifuge tank, centrifuge for 5 minutes at a centrifuge speed of 1500 rpm, pour out and combine the suspended pulp in the upper layer, and obtain purified pulp. Then clean the centrifuge tank after removing the sediment, pour the purified ore slurry into the centrifuge again, set the centrifuge speed to 4500rpm, centrifuge for 7min, pour out the supernatant, scrape out the thick mud at the bottom and stir evenly to obtain Get the concentrated pulp of sepiolite after purification, the solid content of this concentrated pulp is 26.1% after measuring, and its density is 1.15g / ml;

[0046] Take 500mL of concentrated concentrate slurry with a sepiolite solid conte...

Embodiment 3

[0050] Add 1 kg of sepiolite ore powder with D50 less than 10 μm into 15 L of water at a stirring speed of 500 rpm, stir for 30 minutes, stop stirring to form a uniformly dispersed slurry. After 12 hours of natural settlement, the siphon method was used to suck out the suspended slurry in the upper layer. Put it into a centrifuge tank, centrifuge for 5 minutes at a centrifuge speed of 1500 rpm, pour out and combine the suspended pulp in the upper layer, and obtain purified pulp. Then clean the centrifuge tank after removing the sediment, pour the purified ore pulp into the centrifuge again, set the centrifuge speed to 4500rpm, centrifuge for 8min, pour out the supernatant, scrape out the thick mud at the bottom and stir evenly to obtain Get the concentrated pulp of sepiolite after purification, the solid content of concentrated pulp is 30%, and its density is 1.18g / ml;

[0051] Take 500mL of concentrated concentrate slurry with a sepiolite solid content of about 30% after pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com