Acid airflow assistant electrostatic spinning device

A technology of electrospinning and airflow, which is applied in the direction of electrospinning, textile and papermaking, filament/thread forming, etc. It can solve the problems of insufficient jet stretching and insufficient volatilization of solvents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

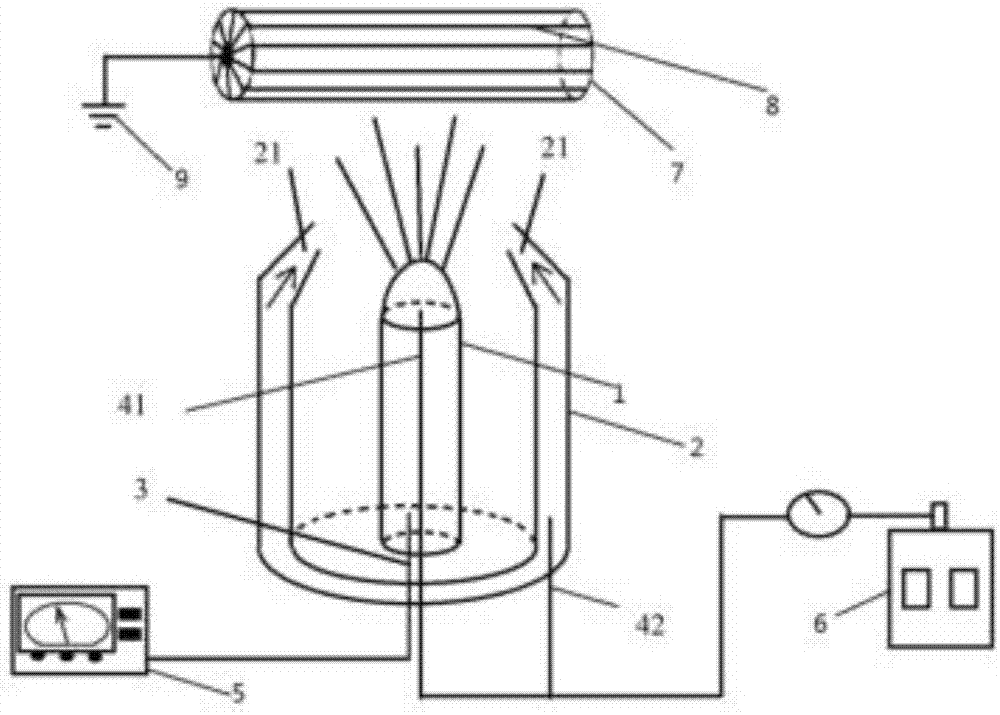

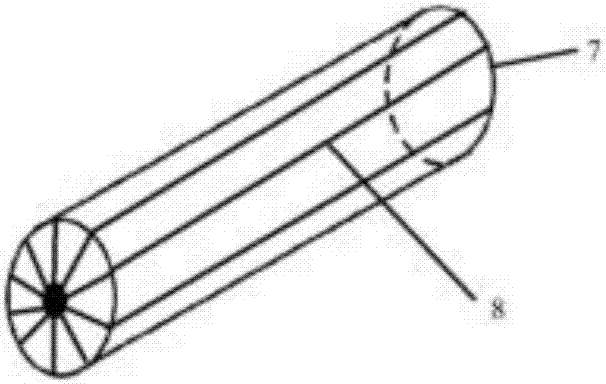

[0016] The invention discloses an acid airflow electrospinning device. The material cylinder can rotate clockwise and counterclockwise intermittently around its rotation axis. The rotation of the material cylinder increases the initial velocity of the jet. In the process of stretching by electric field force, the airflow is assisted at the same time to form a jet around the bottom of the jet. Under the action of mechanical external force, the jet converges. The acidic surrounding blower creates a weakly acidic volatile environment for the volatilization of the solvent in the jet, promotes the volatilization of the solvent, enables the jet to achieve a relatively ideal solvent volatilization effect within a short receiving distance, and helps to improve the porosity of the fiber sex.

[0017] Such as figure 1 As shown, the present invention discloses that it includes a barrel 1, a first air blowing conduit 41 extending into the barrel 1 at one end, an electrode 3 extending int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com