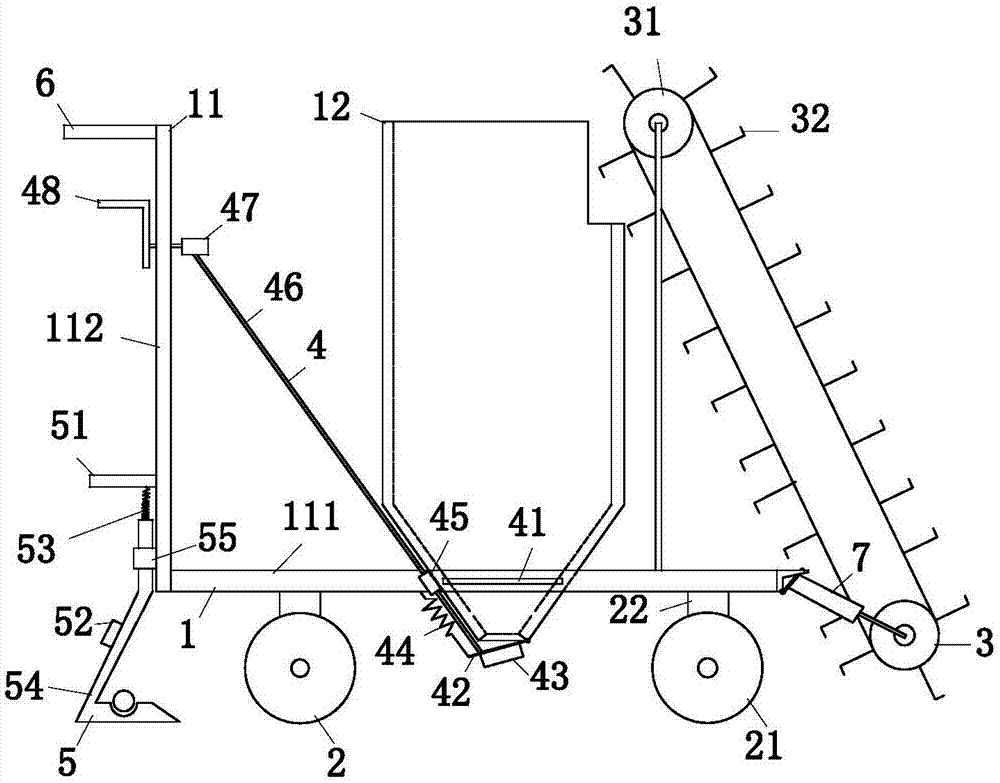

Gravel spreading machine for road construction

A crushed stone spreader, road technology, applied in the direction of roads, roads, road repairs, etc., to achieve the effects of easy promotion and use, simple structure, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

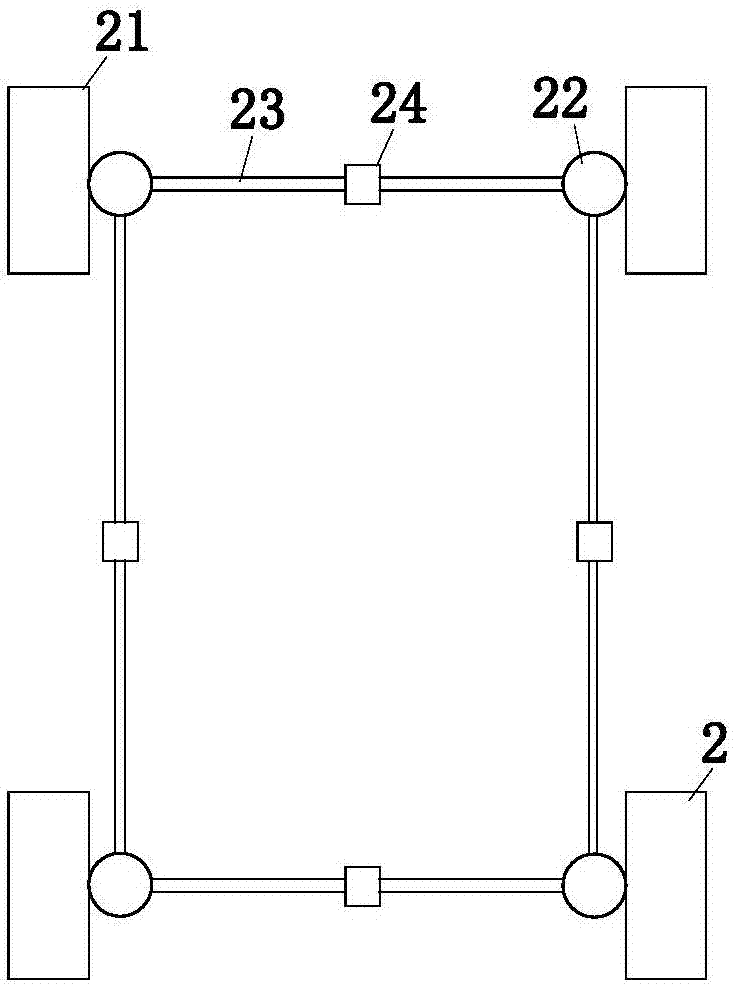

Method used

Image

Examples

Embodiment approach

[0031] As an embodiment of the present invention, the rake tooth unit 32 includes a rake tooth seat 321 and a rake tooth 322. The rake tooth seat 321 is installed on the conveyor belt. The rake tooth seat 321 is provided with a through groove, and one end of the rake tooth 322 passes through a screw. Installed in the through groove of the rake tooth base 321, the distance between the connected rake teeth 322 can be manually adjusted, and the other end of the rake tooth 322 is set in an arc shape. When the distance between the rake teeth 322 does not match the size of the required crushed stone, adjust the distance between the rake teeth 322 by loosening the screws, and tighten the screws after the adjustment is completed to achieve the purpose of adjustment.

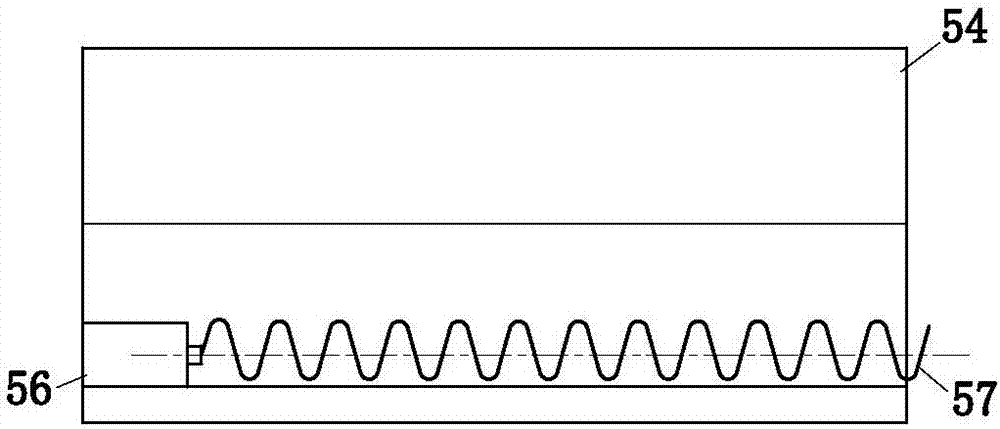

[0032] As an embodiment of the present invention, the trimming module 5 includes a top plate 51, a vibration motor 52, a spring 53, a scraper 54, a guide groove 55, a rotating motor 56 and a shaftless stranding cage 57. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com