Simple assembled house

A simple and simple technology for assembling houses, applied in building materials, building components, wine cellars, etc., can solve the problems of low stability of the house frame, occupying indoor area, collapse, etc., to save indoor use area, good thermal insulation effect, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

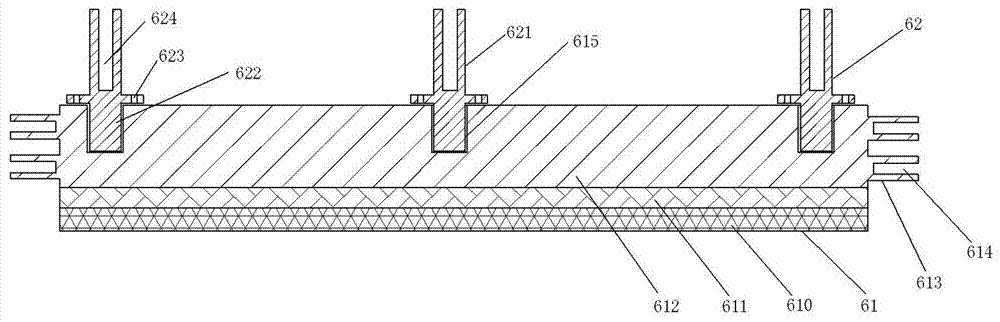

[0033] Such as Figure 1-2 , Figure 4-9 as well as Figure 12-13 As shown, a simple assembled room in Embodiment 1 includes a prefabricated foundation 61, a wall panel, a prefabricated part 62 for fixing the wall panel to the prefabricated foundation 61, and a wall-mounted balcony; the wall The panel includes a wall panel structure 60, a steel frame set inside the wall panel structure 60, a foamed cement layer 55 cast in the gap between the steel frame and the wall panel frame 60, and a reinforcing panel 59 encapsulated on the periphery of the foamed cement layer 55 The wall panel structure 60 is a frame structure; the left side frame of the wall panel structure 60 is provided with an insertion block 57, and the right side frame is provided with an insertion slot 56 that matches the insertion block 57; Sealing strip installation grooves 58 are preset on the periphery of the upper and lower frames of the wall panel structure 60 and the plug-in block 57; the side of the prefa...

Embodiment 2

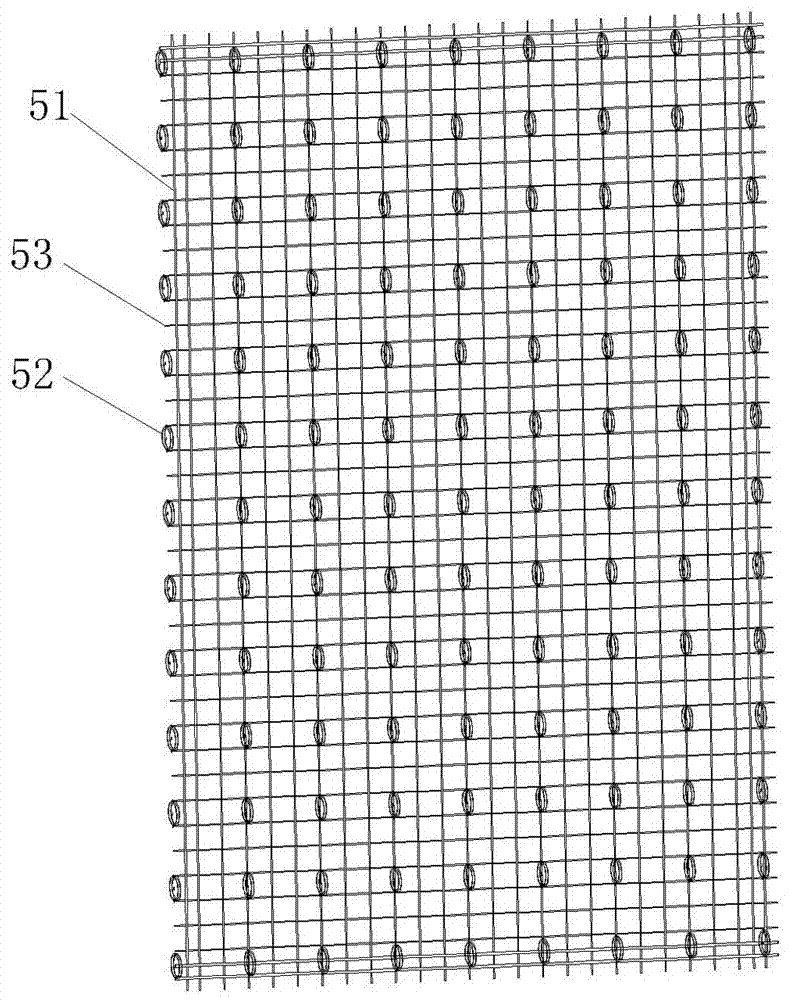

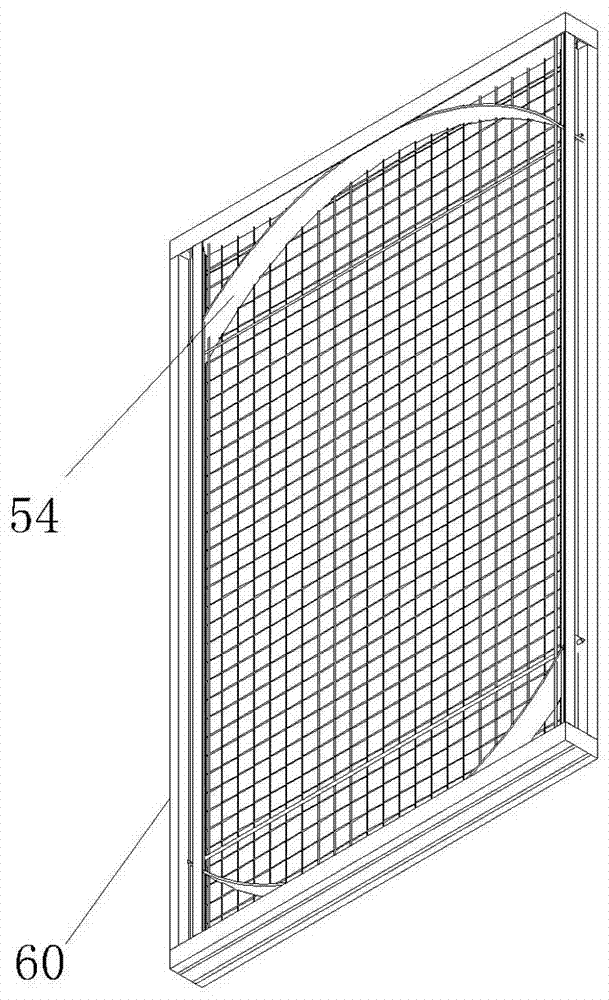

[0041] Such as image 3 , Figure 10-11 as well as Figure 14 As shown, a simple assembled room in embodiment 2, the basic structure of the wall panel is the same as that in embodiment 1, and the steel frame and the wall-mounted balcony are different.

[0042] The steel frame includes vertical reinforcing ribs 51, transverse reinforcing ribs 53 and arched supports 54; the arched supports 54 are two, supporting and connecting the vertical reinforcing ribs 51 and transverse reinforcing ribs 53; the design of the arched supports makes The load-bearing effect of the wall is improved.

[0043] The wall-mounted balcony includes a balcony front panel 1 that is rotatably connected to the wall through a second connecting shaft 6, a side wing panel 2 that is rotatably connected to both sides of the balcony front panel 1 through a first connecting shaft 3, and is rotatably connected to the balcony front panel 1 through a third connecting shaft 13. The movable platen 8 on the top side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com