Nonstandard concrete fracture performance test device

A technology of fracture performance and test device, which is applied in the direction of measuring device, strength characteristics, and testing material strength by applying stable tension/pressure, which can solve the problem of not reflecting the crack resistance performance of large-structure concrete, and achieve a simple, effective and convenient structure. The effect of assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

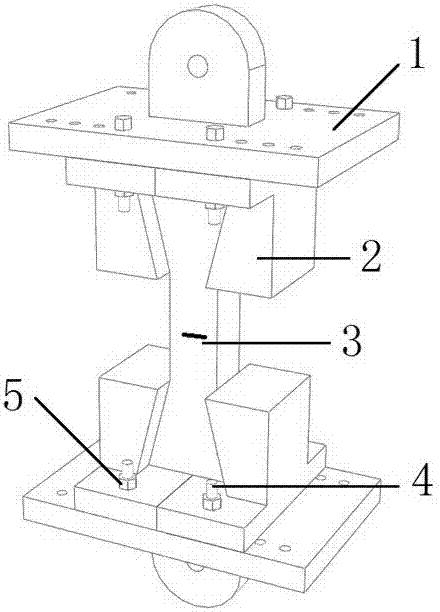

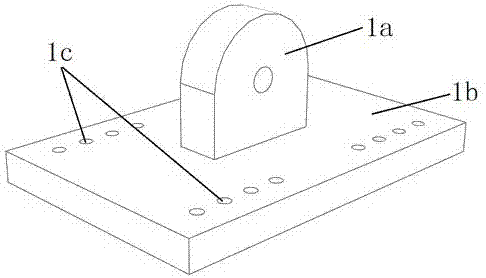

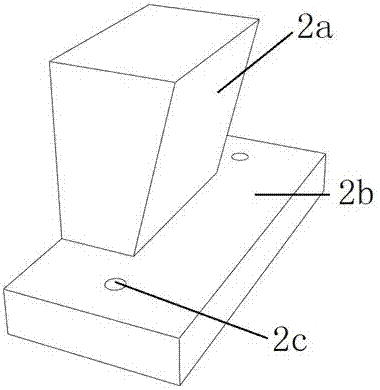

[0014] The non-standard concrete fracture performance test device provided in this embodiment, such as figure 1 , including: a force transmission plate 1 arranged at both ends of the concrete specimen 3 and a clamping block set installed on the force transmission plate 1 for clamping the concrete specimen 3; the clamping block set includes two clamping blocks 2 arranged oppositely. Such as image 3 , The clamp block 3 includes a clamping portion 2a and a mounting plate 2b fixed to each other, and the mounting plate 2b has a mounting hole 2c. Such as figure 2 The force transmission plate 1 includes a force transmission base plate 1b and hinged ears 1a fixed on the outside of the force transmission base plate 1b. There are several fixing holes 1c on the force transmission base plate 1b, and the clamp block 2 and the force transmission plate 1 pass through the installation holes. 2c is fixedly connected with the bolt 4 of the fixing hole 1c, and the bolt 4 is tightened with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com