Protective gas device for laser processing

A laser processing and shielding gas technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable air flow, uneven gas volume on the processing surface, and protection of dead angles, so as to inhibit diffusion and avoid weld bead oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

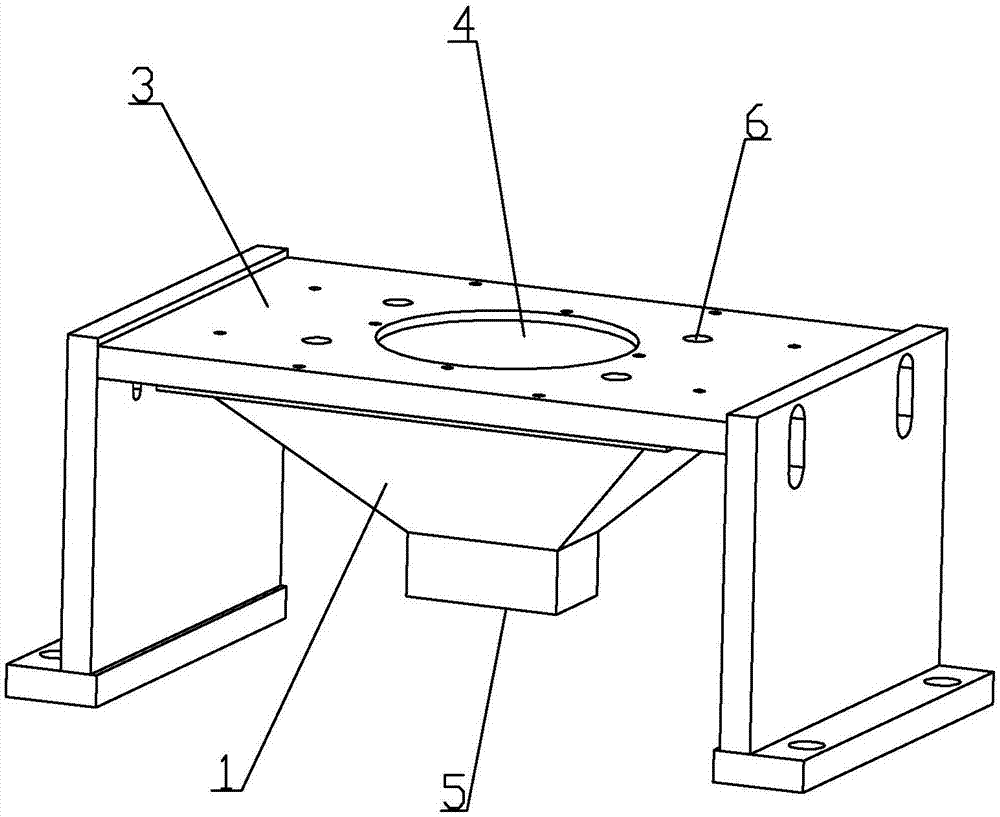

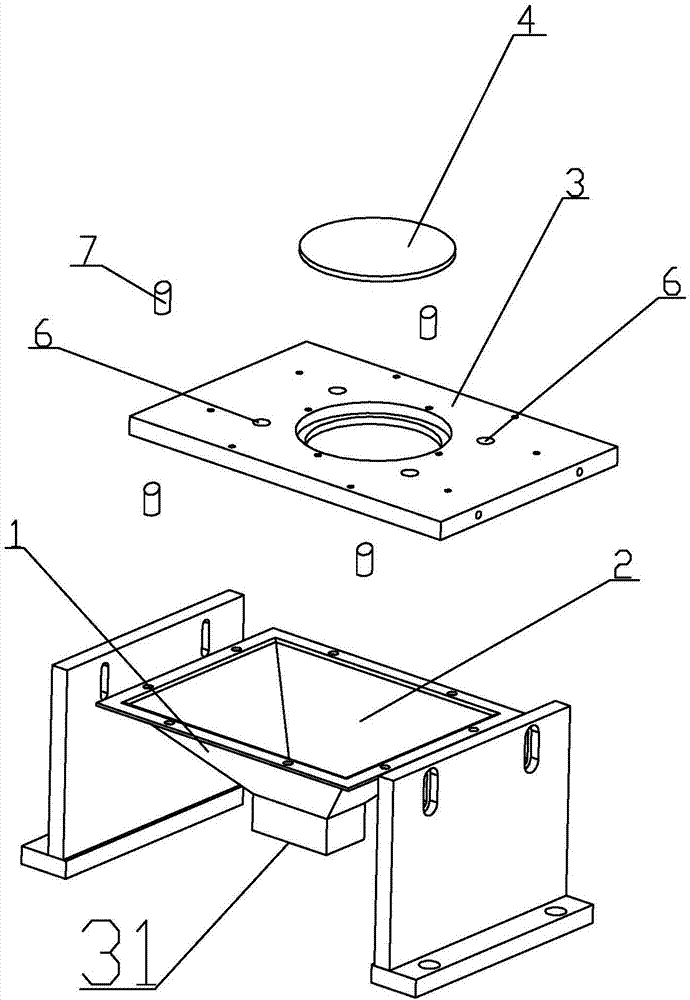

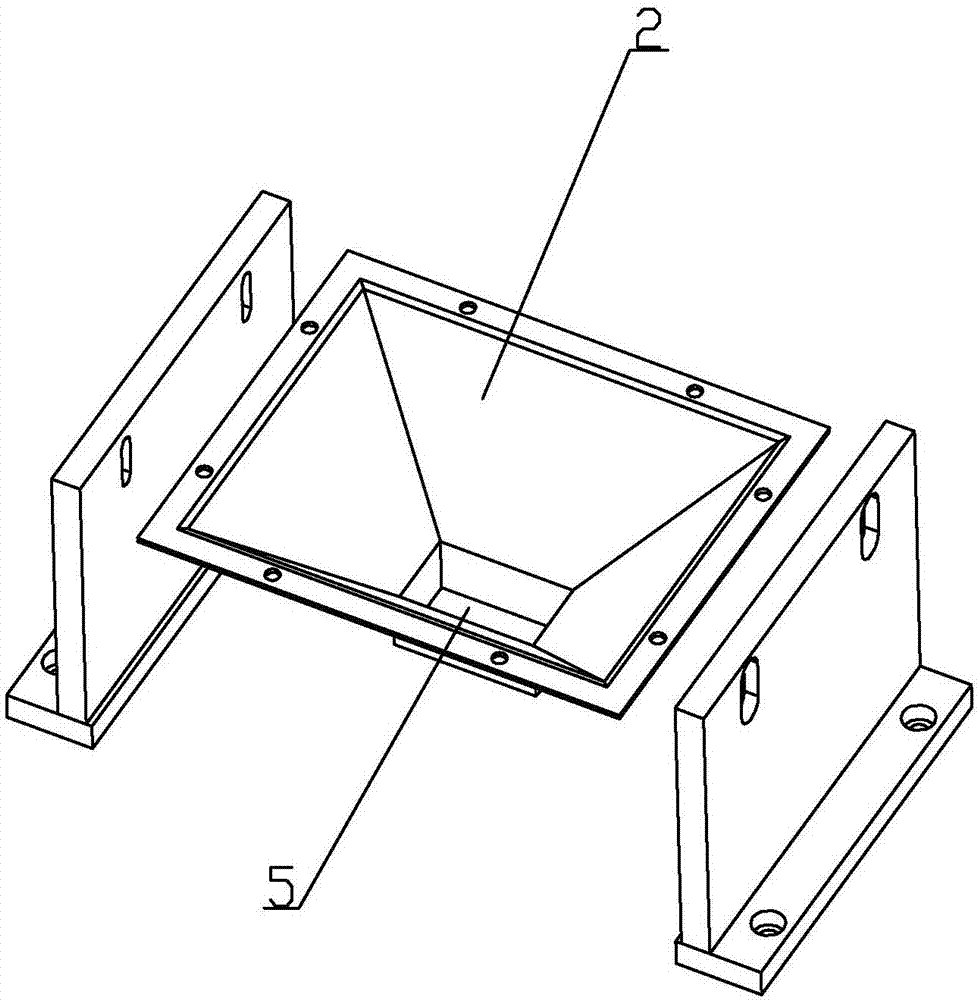

[0013] like Figure 1 to Figure 3 As shown, a shielding gas device for laser processing includes a housing 1. A shielding gas chamber 2 and a cover plate 3 for covering the shielding gas chamber 2 are arranged in the housing 1. The upper and lower ends of the shielding gas chamber 2 are opened, and the cover The plate 3 covers the upper opening of the protective gas cavity 2, the protective gas cavity 2 is an inverted conical cavity, and the cover plate 3 is provided with a lens 4 for the laser to penetrate into the protective gas cavity 2. By setting the lens 4, the Laser focus to reduce energy loss. The bottom of the protective gas chamber 2 is provided with an air outlet 5 aligned with the workpiece to ensure that the protective gas can effectively protect the workpiece, and the protective gas can evenly isolate the external air in the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com