Single-engine sanitation vehicle power system and power control method thereof

A power system, single-engine technology, applied in control devices, vehicle components, auxiliary drive devices, etc., can solve problems such as complex structure and control, and achieve the effects of simple structure and control, reduced self-weight, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

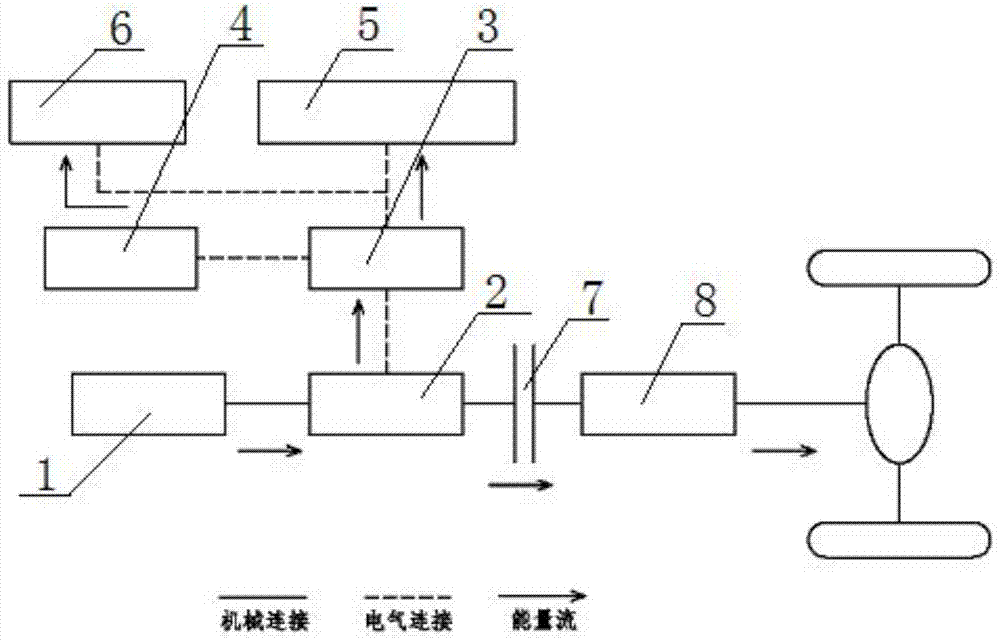

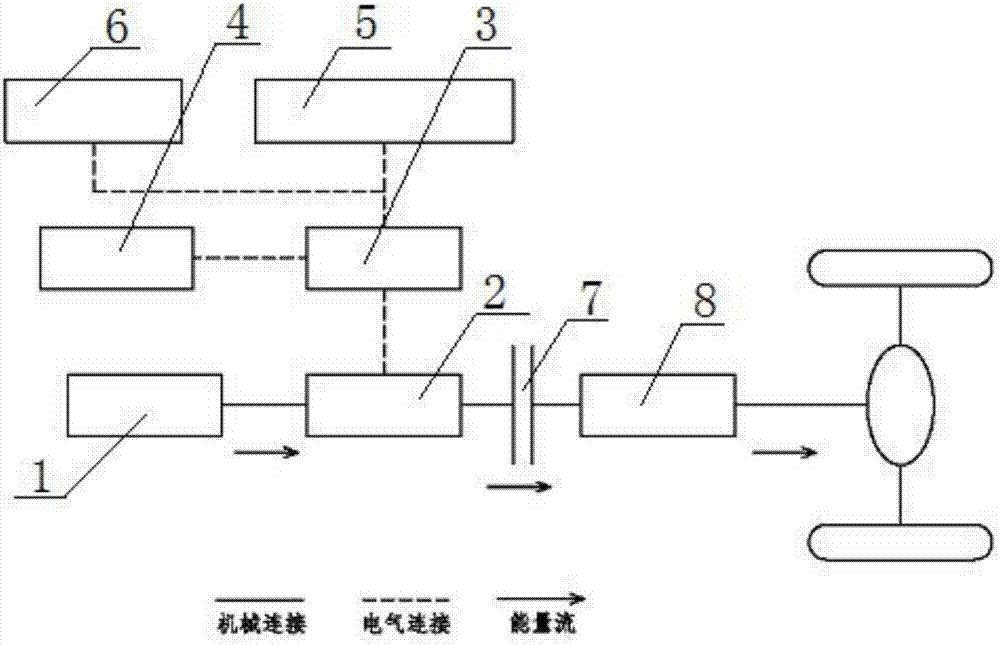

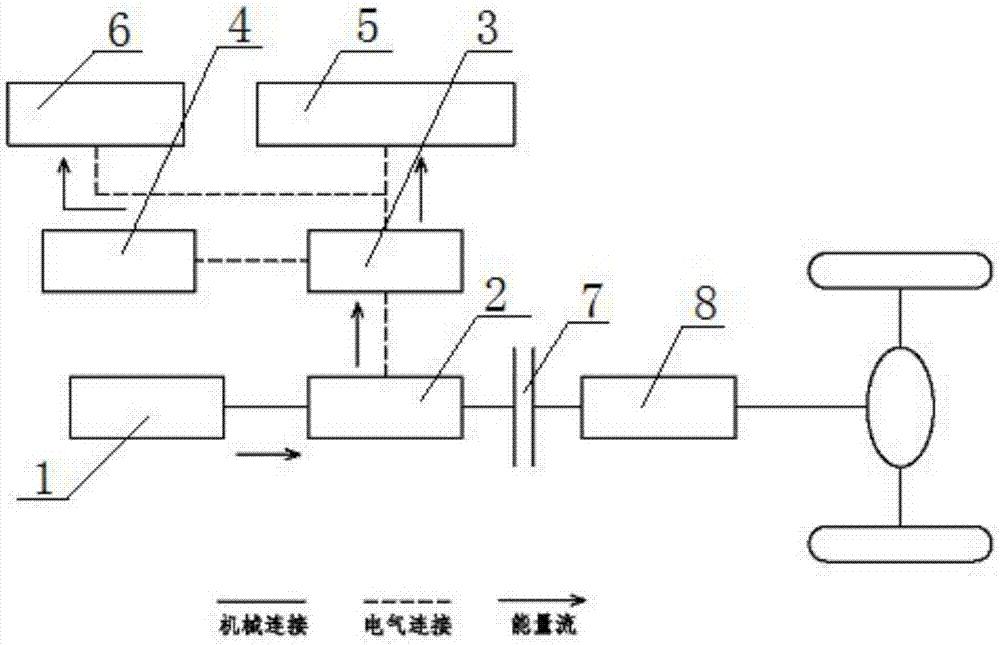

[0044] see Figure 1 to Figure 4 , a power system for a single-engine sanitation vehicle, comprising an engine 1, an ISG motor 2, and a PE controller 3, the engine 1 is sequentially connected to a gearbox 8 through an ISG motor 2, a clutch 7, and the ISG motor 2 is connected to the engine A high-power ISG motor fixedly connected to the crankshaft of 1, the PE controller 3 is equipped with a bodywork command receiving module 31, a motor drive module 32, a current access processing module 33, a vehicle-mounted operation drive module 34, and a bodywork accessory drive module 35 , the input end of the uploading instruction receiving module 31 is connected with the output end of the uploading controller 4, the output end of the uploading instruction receiving module 31 is connected with the input end of the ISG motor 2 through the motor drive module 32, and the ISG motor 2 The output end of the on-board operation device 5 is connected to the input end of the vehicle-mounted operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com