Construction method of water-borne non-curing coating and coiled material composite waterproof system

A construction method and non-curing technology, applied in asphalt coatings, coatings, roof insulation materials, etc., can solve the problems of hollow waterproof layer, large solvent volatilization, high fire protection requirements, etc., to increase rigidity and impact resistance, The effect of the degree of dryness and humidity is not required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

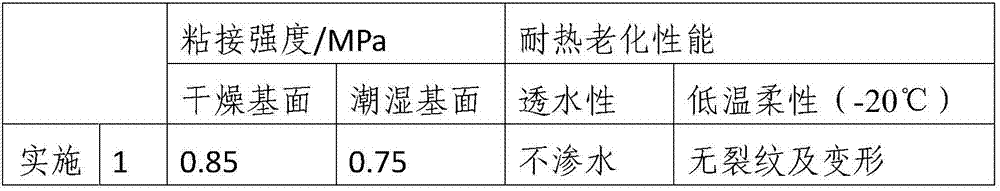

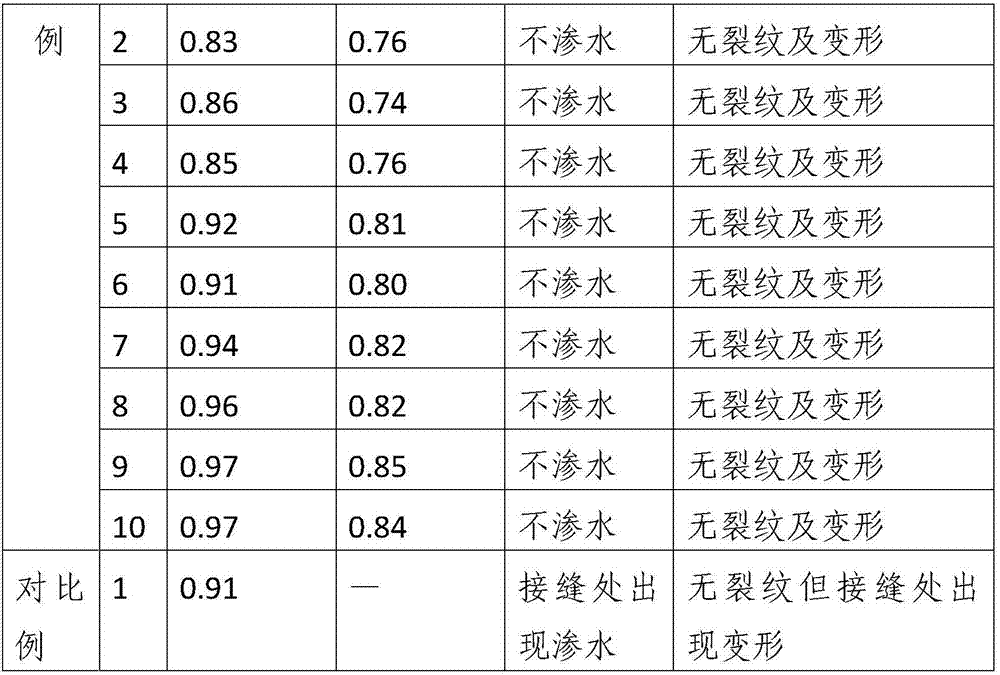

Examples

Embodiment 1

[0023] The construction method of the water-based non-curing paint of embodiment 1 and coiled material composite waterproofing system comprises the steps:

[0024] S1: Spraying water-based non-curing paint on the substrate layer;

[0025] S2: Paste the waterproof membrane layer on the surface of S1 paint.

[0026] In embodiment 1, the water-based non-curing rubber asphalt coating containing cationic emulsified asphalt is used, which is composed of component A and component B in proportion, wherein component A is composed of 75 parts of cationic rubber modified emulsified asphalt, 10 parts of tackifying resin emulsion, Composed of 5 parts of octyl ester, 2 parts of interface agent, 2 parts of antifreeze and 2 parts of anti-aging agent; component B is composed of 10 parts of inorganic salt, 15 parts of buffer and 60 parts of water; the mass ratio of component A to component B is 30:1. The above-mentioned tackifying resin is C5 petroleum resin, the tackifying resin emulsion is ...

Embodiment 2

[0030] The difference between Example 2 and Example 1 is that the waterproof membrane is type I of self-adhesive polymer modified asphalt waterproof membrane;

Embodiment 3

[0032] The difference between embodiment 3 and embodiment 1 is that the waterproof membrane is SBS / APP modified asphalt waterproof membrane;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com