Composite pipe and manufacturing and mounting method thereof

A technology of composite pipes and pipes, which is applied in the field of pipes, can solve problems such as installation difficulties, and achieve the effects of increased ring rigidity, easy coiling, and fewer joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

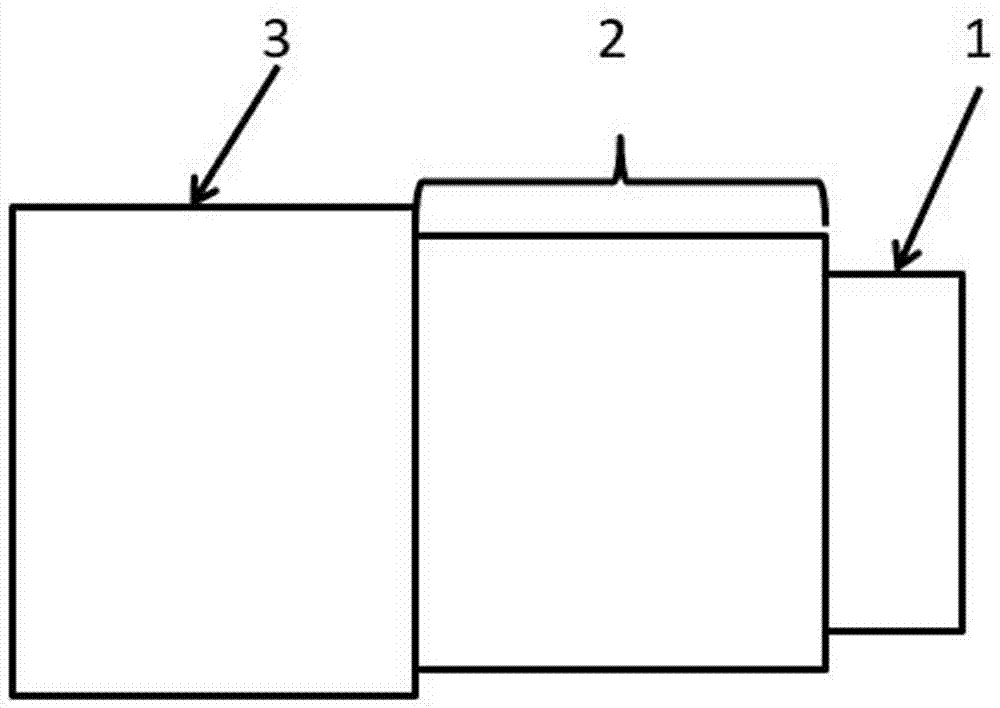

Image

Examples

Embodiment 1

[0035] A kind of composite pipe, this composite pipe comprises reinforcing material layer, inner liner and outer protection layer, and pipe inner diameter is 150mm, the thickness of inner liner is 11.5mm, the thickness of reinforcement material layer is 6.4mm, and the thickness of outer protection layer is 7.5mm. The reinforcement layer contains fiber-reinforced prepreg, inside the reinforcement layer there is an inner liner made of polyethylene, and outside the reinforcement layer there is an outer protective layer made of nylon. The fiber reinforced prepreg contains 4 parts by weight of epoxy resin and 6 parts by weight of carbon fiber.

[0036] The method for manufacturing the above-mentioned composite pipe includes the following steps: use a winding machine to hoop-wind the fiber fabric thermoplastic prepreg on the inner liner polyethylene, and wrap the outer protective layer nylon on the fiber fabric thermoplastic prepreg tape.

[0037] Coil the composite pipe and lay it...

Embodiment 2

[0039] A kind of composite pipe, this composite pipe comprises reinforcing material layer, inner liner and outer protection layer, and pipe internal diameter is 100mm, the thickness of inner liner is 7.5mm, the thickness of reinforcing material layer is 3.2mm, and the thickness of outer protection layer is 5.5mm. The reinforcement layer contains fiber-reinforced prepreg, inside the reinforcement layer there is an inner liner made of polyether ether ketone, and outside the reinforcement layer there is an outer protective layer made of polyvinylidene fluoride, fiber-reinforced prepreg The material contains 3 parts by weight of phenolic resin and 7 parts by weight of glass fiber.

[0040] The method for manufacturing above-mentioned composite pipe comprises the steps:

[0041] A winding machine is used to hoop-wind the fiber fabric thermoplastic prepreg on the inner lining layer polyether ether ketone, and wrap the outer protective layer polyvinylidene fluoride on the fiber fabr...

Embodiment 3

[0044] A kind of composite pipe, this composite pipe comprises reinforcing material layer, inner liner and outer protective layer, composite pipe internal diameter is 150mm, the thickness of inner liner is 0.5mm, the thickness of reinforcing material layer is 6.4mm, the thickness of outer protective layer 0.5mm. The reinforcement layer contains fiber-reinforced prepreg, inside the reinforcement layer there is an inner liner made of nylon, and outside the reinforcement layer there is an outer protective layer made of polyethylene. The fiber-reinforced prepreg contains 5 parts by weight of unsaturated polyester and 5 parts by weight of aramid fiber.

[0045] The method for manufacturing above-mentioned composite pipe comprises the steps:

[0046] Using a winding machine, the fiber fabric thermoplastic prepreg is hoop-winded on the inner liner nylon, and the outer protective layer polyethylene is wrapped on the fiber fabric thermoplastic prepreg tape.

[0047] Coil the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com