Integration and joint debugging method of secondary equipment based on virtual machine

A technology of secondary equipment and virtual machine, applied in the direction of electrical components, circuit devices, information technology support systems, etc., can solve the problems of frequent changes of debugging personnel, lack of standardized procedures for joint debugging organizations, and ununiform testing and evaluation, etc., to achieve improvement Test the configuration and operation convenience, improve the intelligent level of joint debugging, and shorten the effect of equipment debugging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below in conjunction with the accompanying drawings.

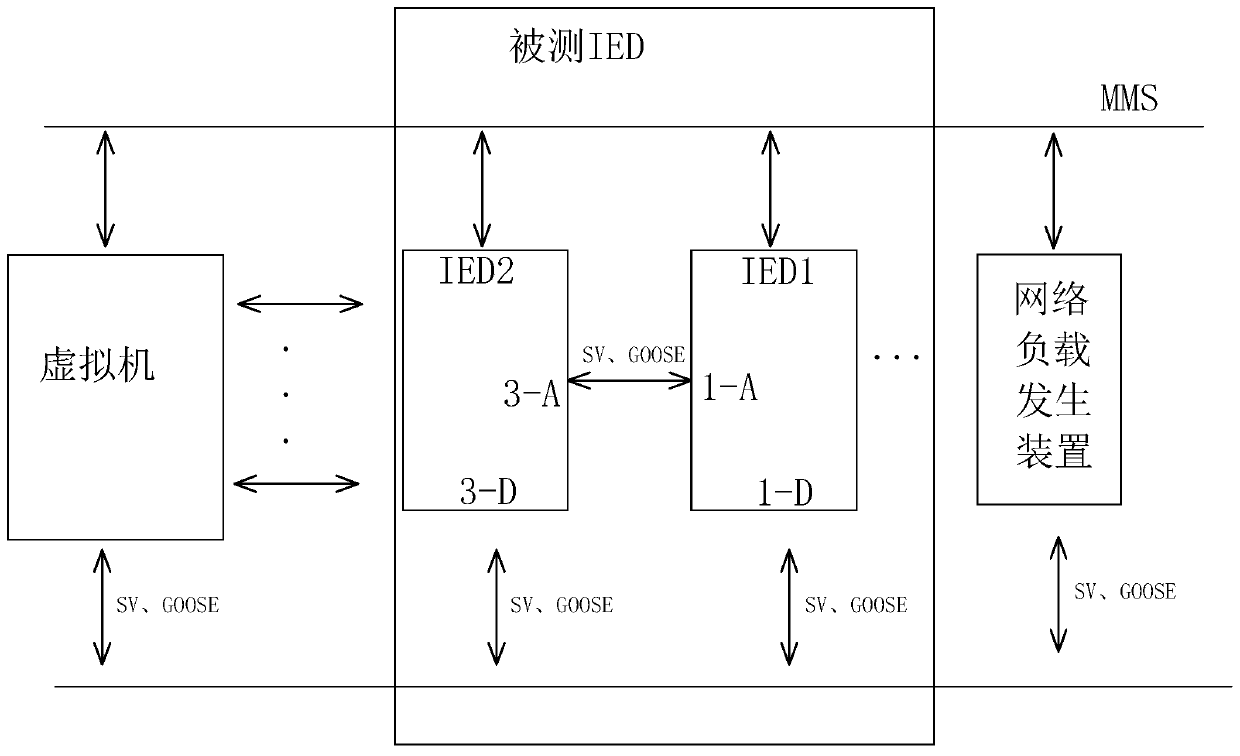

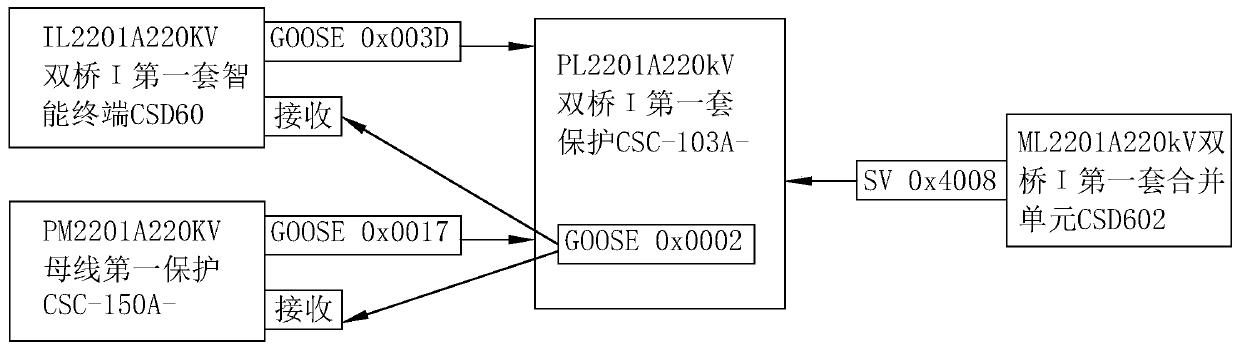

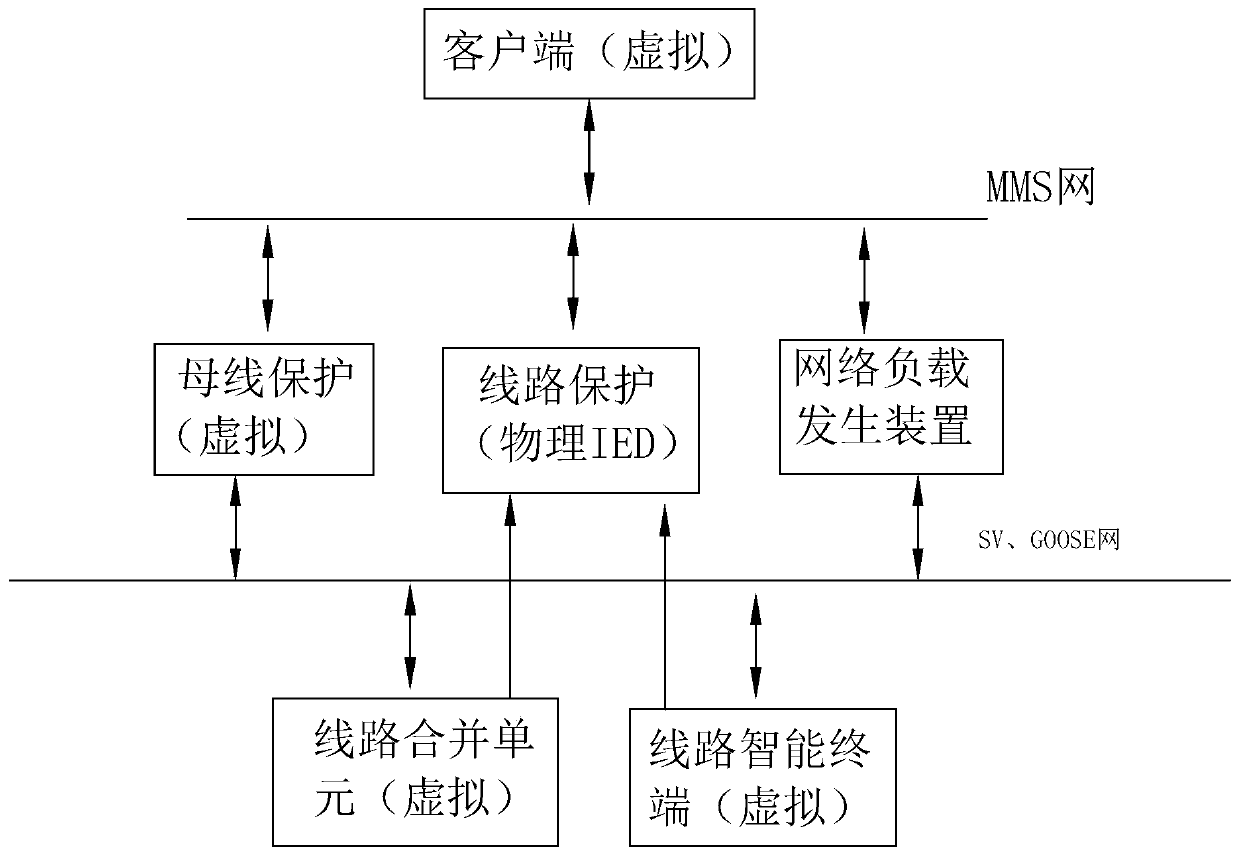

[0058] A 220kV substation usually has more than 100 protection-related IEDs (protection devices, merging units, and intelligent terminals). With the addition of other IEDs such as measurement and control, the total number of IEDs in the substation will be even greater. In the laboratory environment, simulating the real environment of the site to carry out the factory joint commissioning test requires a large number of actual IEDs of various models to conduct auxiliary tests. Smart substations use optical fiber to transmit SV and GOOSE signals, so it is necessary to use digital simulation to test IED equipment. Digital simulation is divided into full simulation and partial simulation. If digital simulation is used for all IEDs in a substation, large hardware overhead is required, and the system formed will be very complicated, and the test configuration and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com