Electric self-heating die and forming method of glassfiber reinforced plastics

A glass fiber, self-heating technology, used in the field of electrothermal self-heating molds and glass fiber reinforced plastics, can solve the problems of uneven temperature, full of tiny cracks, inconsistent cooling speed, etc., to achieve uniform cooling rate and increase surface thickness. Consistency, the effect of improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

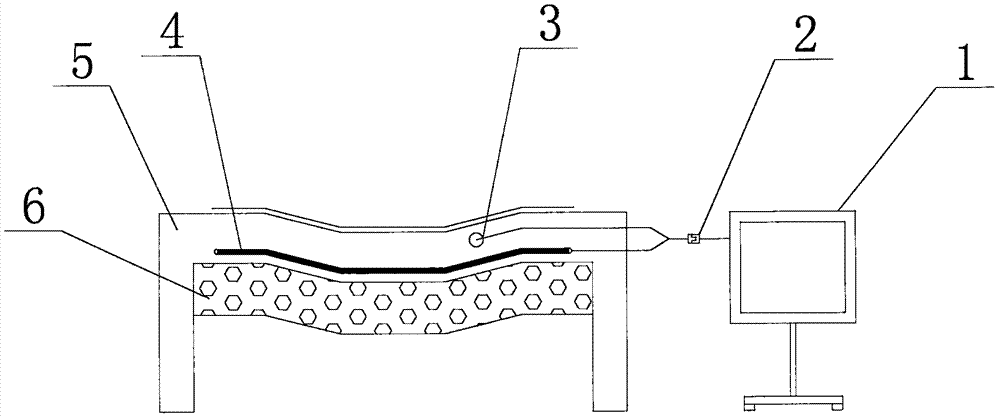

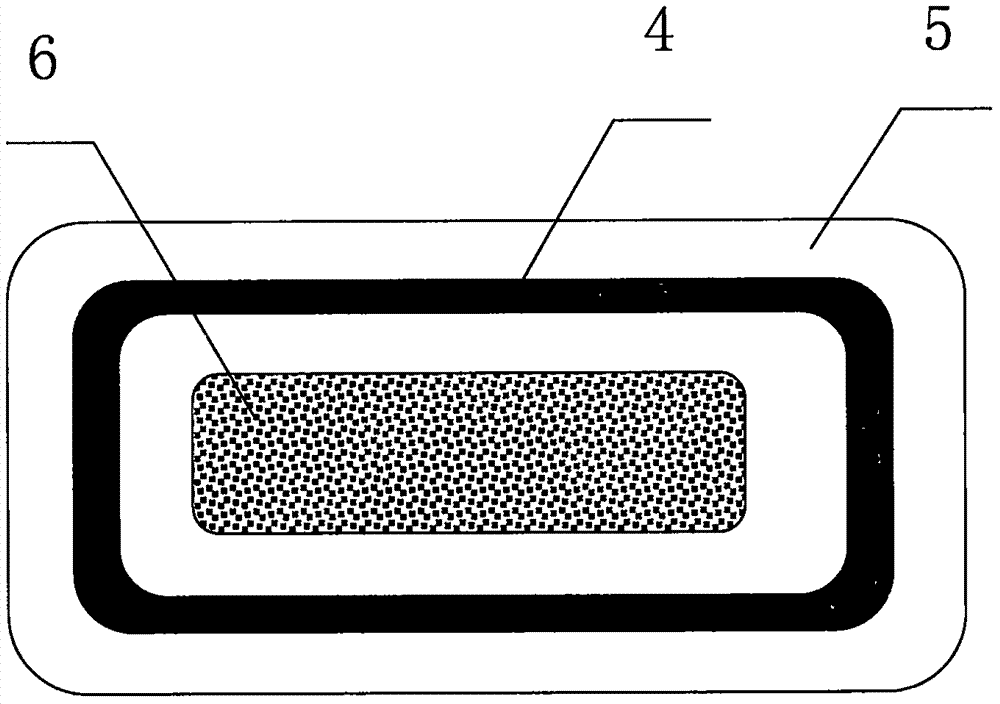

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, as Figure 1 ~ Figure 2 As shown, an embodiment of the present invention is an electric heating self-heating mold, including a mold base 5 and a controller 1, a soft electric heating pipeline 4 is arranged in the mold base 5, and the mold under the soft electric heating pipeline 4 A semiconductor cooling chip 6 is arranged in the base 5 , and a temperature sensor 3 is also arranged in the mold base 5 , and the soft electric heating pipeline 4 , the semiconductor cooling chip 6 and the temperature sensor 3 are all connected to the controller 1 . The soft electric heating pipeline 4 and the semiconductor cooling chip 6 are arranged in a ring in the horizontal direction, wherein the soft electric heating pipeline 4 is arranged on the outer ring, and the semiconductor cooling chip 6 is arranged on the inner ring.

[0018] The controller 1 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com