Preparation method for preparing nylon porous material on large scale

A porous material, nylon technology, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of poor heat resistance, difficult industrialization, high production cost, etc., and achieve the production method Simple and easy to operate, large specific surface area, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

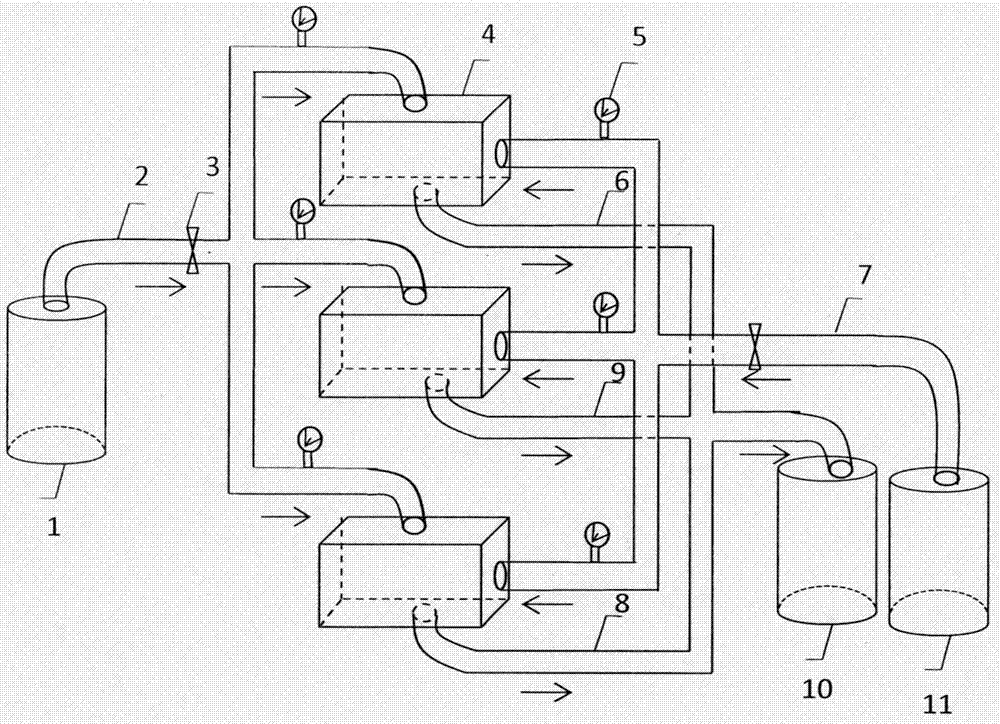

Method used

Image

Examples

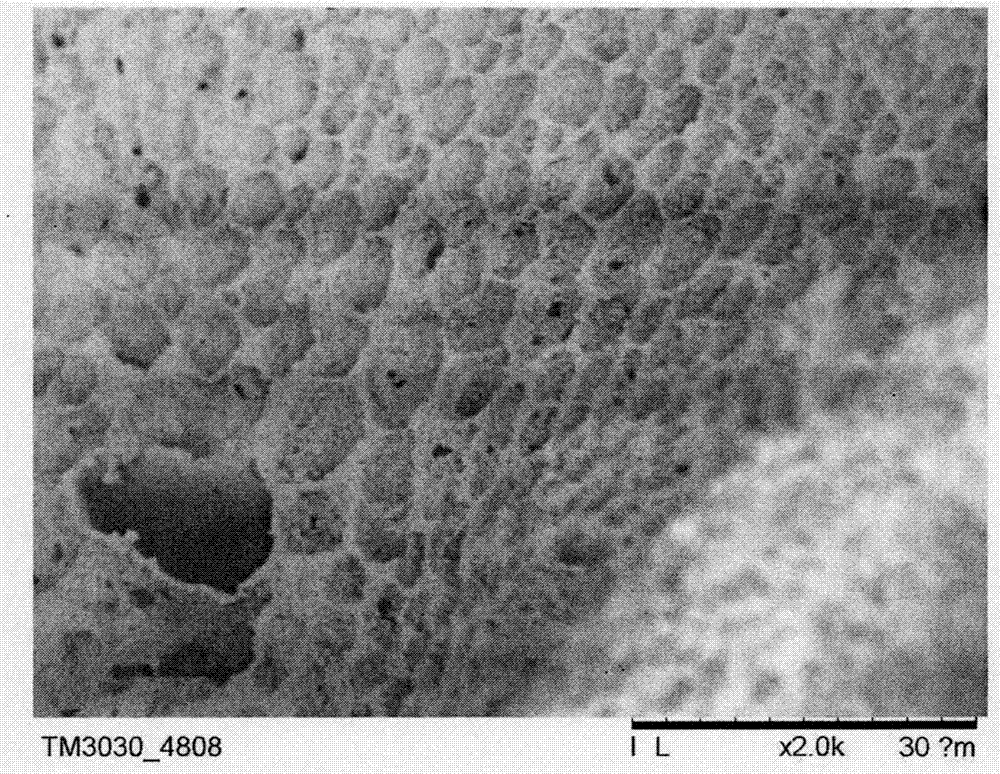

Embodiment 1

[0030] A kind of nylon porous material is characterized in that it is made of the raw material of following parts by weight (g): nylon 6 (PA6) 16, anhydrous formic acid 84, sodium bicarbonate 3, distilled water 97

[0031] A kind of preparation method of nylon porous material as claimed in claim 2, is characterized in that comprising the following steps:

[0032] (1) Nylon 6 and anhydrous formic acid were weighed and mixed according to a certain mass ratio, and stirred with a magnetic stirrer at room temperature for 3 hours until completely dissolved.

[0033] (3) A certain quality of sodium bicarbonate is mixed with water to form a solution with a mass concentration of 3%.

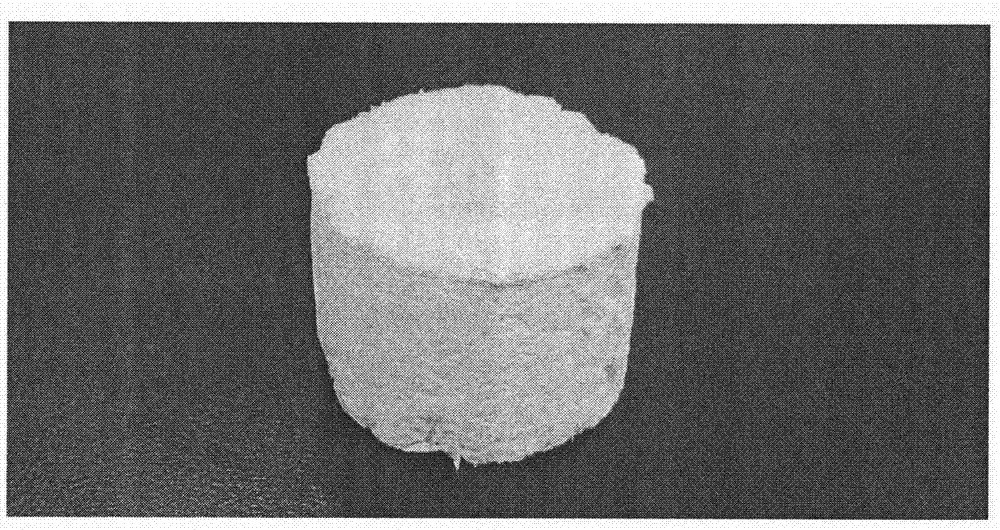

[0034] (4) Take 6ml of nylon / formic acid solution and put it into a mold with a capacity of 14ml, inject NaHCO 3 aqueous solution, producing a large amount of CO 2 A porous material is formed, and the porous material is taken out after the reaction is complete.

[0035] (5) After washing with water, pu...

Embodiment 2

[0038] A kind of nylon porous material is characterized in that it is made of the raw material of following parts by weight (g): nylon 6 (PA6) 16, anhydrous formic acid 84, sodium bicarbonate 4, distilled water 96

[0039] A kind of preparation method of nylon porous material as claimed in claim 2, is characterized in that comprising the following steps:

[0040] (1) Nylon 6 and anhydrous formic acid were weighed and mixed according to a certain mass ratio, and stirred with a magnetic stirrer at room temperature for 3.5 hours until completely dissolved.

[0041] (2) A certain quality of sodium bicarbonate is mixed with water to form a solution with a mass concentration of 4%.

[0042] (3) Take 7ml of nylon / formic acid solution and put it into a mold with a capacity of 14ml, inject NaHCO 3 aqueous solution, producing a large amount of CO 2 A porous material is formed, and the porous material is taken out after the reaction is complete.

[0043] (5) After washing with water, ...

Embodiment 3

[0046] A kind of nylon porous material is characterized in that it is made of the raw material of following parts by weight (g): nylon 66 (PA66) 16, anhydrous formic acid 84, sodium bicarbonate 4, distilled water 96

[0047] A kind of preparation method of nylon porous material as claimed in claim 1, is characterized in that comprising the following steps:

[0048] (1) Nylon 66 and anhydrous formic acid were weighed and mixed according to a certain mass ratio, and stirred with a magnetic stirrer at room temperature for 3 hours until completely dissolved.

[0049] (3) A certain quality of sodium bicarbonate is mixed with water to form a solution with a mass of sodium bicarbonate of 4%.

[0050] (4) Take 6ml of nylon / formic acid solution and put it into a mold with a capacity of 14ml, inject NaHCO 3 aqueous solution, producing a large amount of CO 2 A porous material is formed, and the porous material is taken out after the reaction is complete.

[0051] (5) After washing wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Absorption rate | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com