Steel beam and steel column unilateral connecting joint capable of being repaired after earthquake and steel structure building

A technology for connecting nodes and steel beams and columns, which is applied in the direction of construction and building construction, can solve the problems of high assembly cost, easy cracking of welds, secondary damage, etc., to reduce repair costs, avoid fracture damage, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

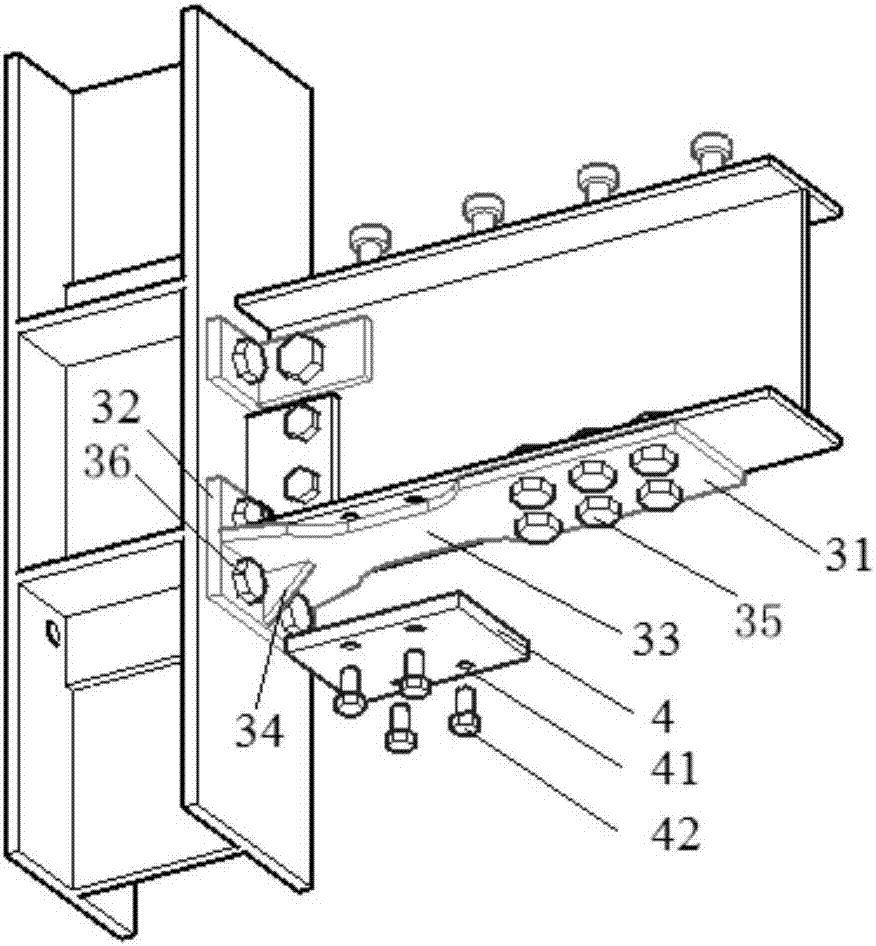

[0051] like figure 2 and Figure 4 As shown, the end of the first connecting plate 31 adopts an enlarged section form, the weakened area 33 in the middle of the first connecting plate 31 adopts a mixed cutting method of circular arc and straight line, and the third bolt holes 311 are arranged side by side, wherein Figure 4 (a) is a T-shaped core plate, Figure 4 (b) is an L-shaped core plate.

example 2

[0053] like Figure 5 As shown, the end of the first connecting plate 31 adopts a non-enlarged cross-sectional form, the weakened area 33 in the middle of the first connecting plate 31 is cut in a mixed manner of circular arc and straight line, and the third bolt holes 311 are arranged side by side.

example 3

[0055] like Image 6 As shown, the end of the first connecting plate 31 adopts a non-enlarged section form, the weakened area 33 in the middle of the first connecting plate 31 adopts a straight line cutting method, and the third bolt holes 311 are arranged side by side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap