Device and method for reinforcing formwork on single-side of retaining wall of basement

A single-side formwork support and reinforcement device technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problem that the floor wall and beam slab cannot be formed at one time and reinforce the frame body Unable to connect, low turnover utilization rate and other problems, to achieve the effect of high turnover material utilization rate, low cost and high turnover rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following non-limiting examples illustrate the invention.

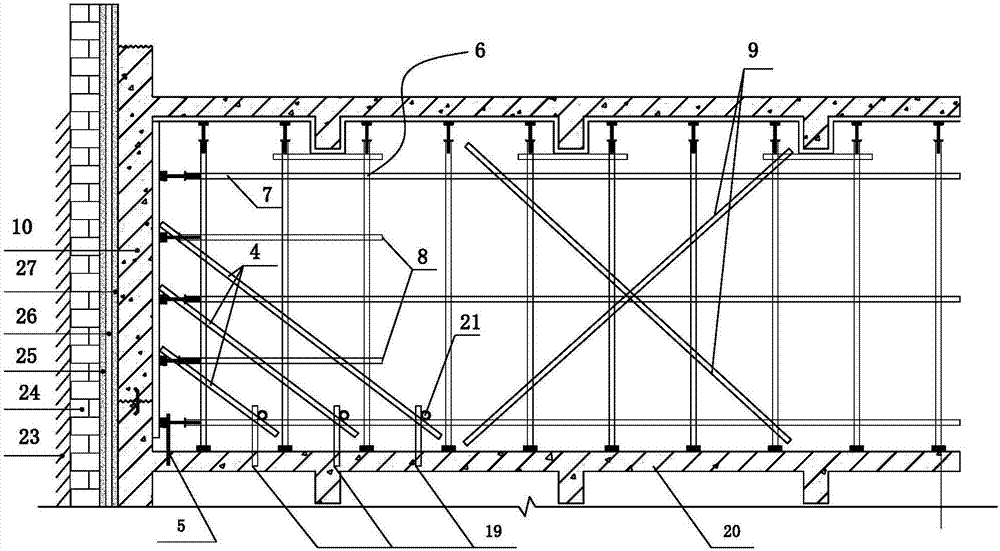

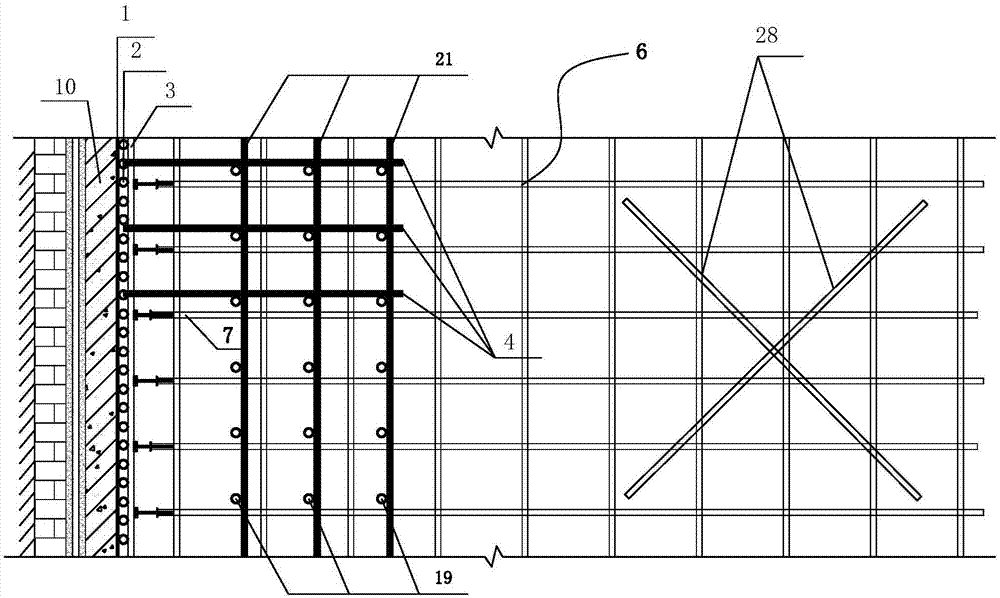

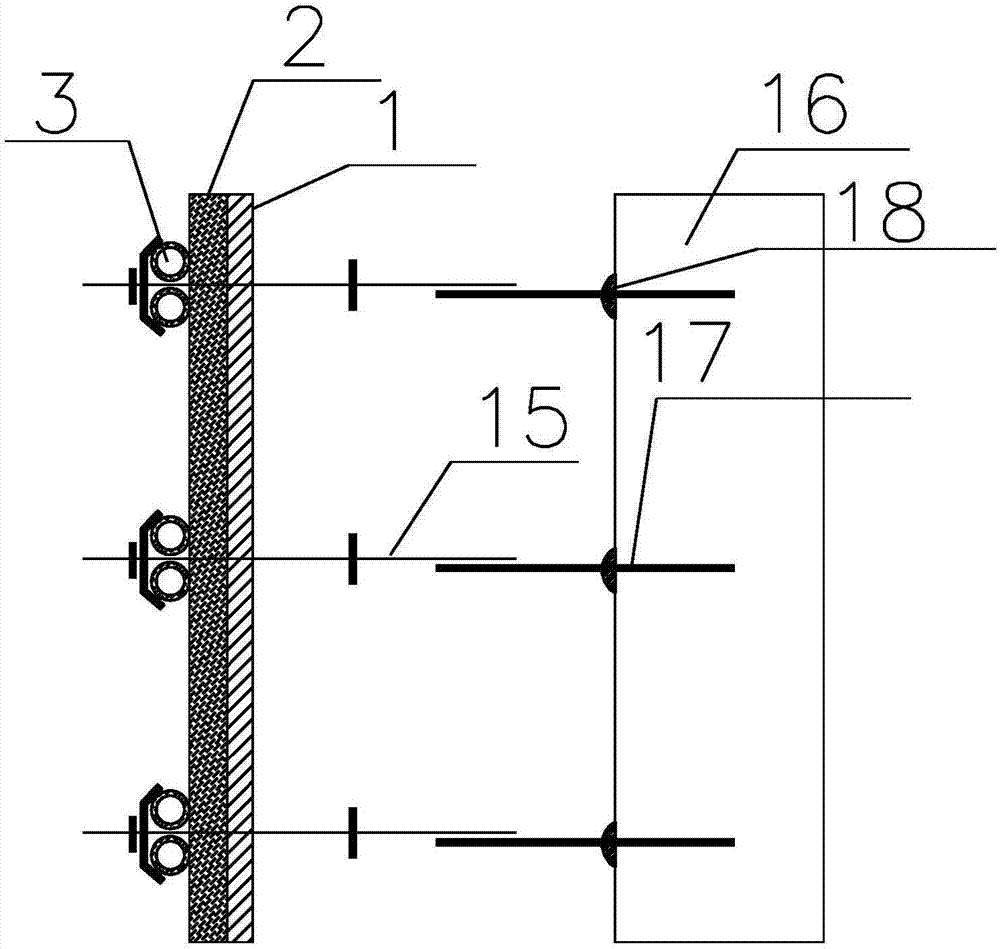

[0046] refer to figure 1 , 2 As shown, a single-side formwork reinforcement device for a basement retaining wall includes a formwork 1, a secondary beam 2, a main beam 3, a horizontal support, an oblique support 4, an anti-floating tie rod 5, a row anchor structure and a full hall frame 6, and the full hall frame 6 is located in the floor and its horizontal rod 7 is used as a horizontal support, and the horizontal support also includes several horizontal support rods 8 arranged between the horizontal rods 7 of the hall frame 6, refer to figure 1 Shown are two rows of horizontal support rods 8; the mansion frame 6 is provided with a vertical scissors brace 9 and a horizontal scissors brace 28, and the vertical scissors brace 9 is vertically arranged in the direction of the retaining wall 10. The retaining wall 10 is provided with formwork 1, secondary beams 2 and main beams 3 in turn on the indoor side, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com