Forced-circulation axial flow pump

A forced-circulation, axial-flow pump technology, applied to pumps, pump components, components of pumping devices for elastic fluids, etc., can solve the problems of troublesome assembly and disassembly, poor operation stability, large pump shaft cantilever, etc. Quick and easy installation, increased rigidity, and the effect of shortening the cantilever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

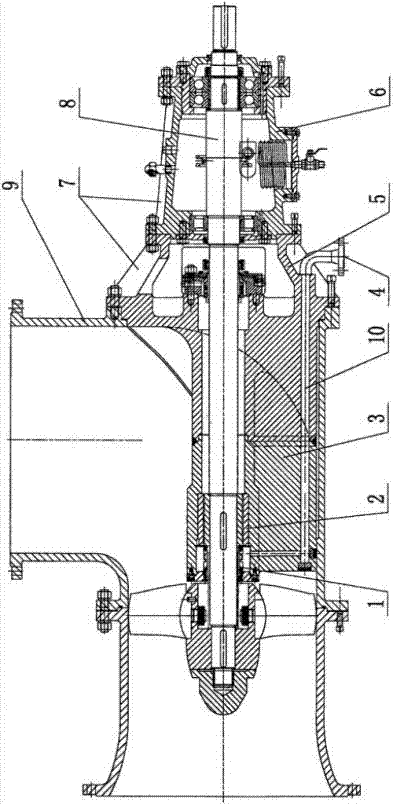

[0012] In the accompanying drawings, the forced circulation axial flow pump of the present invention is mainly composed of a pump body, a pump shaft, an impeller, a pump cover and a bearing body, the pump shaft 8 is supported by the bearing body 6, and the tail end of the pump shaft 8 is equipped with an impeller; the pump A mechanical seal device 1 and a guide bearing 2 are sequentially installed on the shaft 8 close to the end of the impeller; the guide bearing 2 is located in the support tube 3 and supported by the support tube 3, and the right end of the support tube 3 is welded with the pump cover 5; The support shortens the cantilever of the pump shaft at the impeller end, increases the rigidity of the pump shaft, enhances the stability of the rotor parts, and prolongs the service life of the equipment; the mechanical seal device completely isolates the shaft from the conveying medium, effectively preventing the shaft from wearing and tearing Corrosion reduces equipment m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com