Thrust bearing for silicone oil damper

A technology of thrust bearings and shock absorbers, which is applied in the direction of bearings, bearing components, shafts and bearings, can solve problems such as uneven wear and poor wear resistance, achieve low production costs, long service life, and solve uneven wear sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

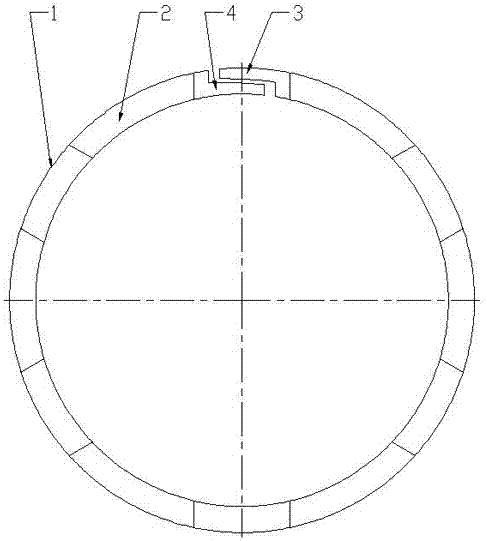

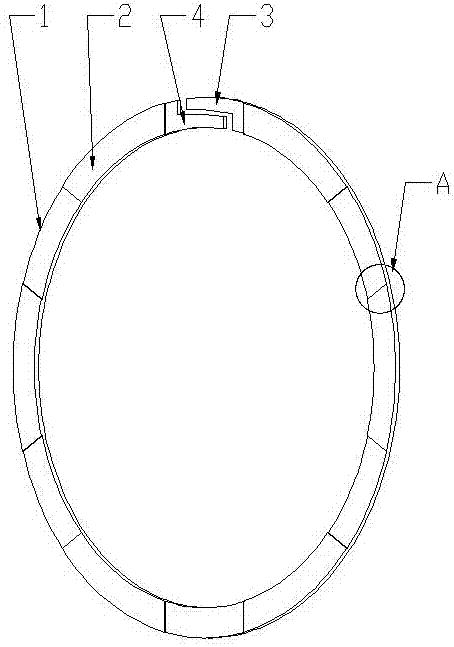

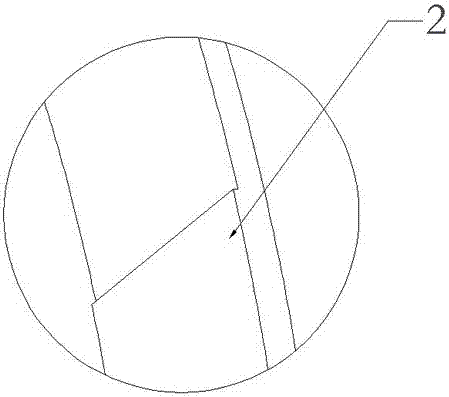

[0014] like figure 1 , figure 2 and image 3 As shown, the thrust bearing for the silicone oil shock absorber includes a bearing body 1, the bearing body 1 is in the shape of an open ring, and one end surface of the bearing body 1 is provided with a plurality of arc-shaped bosses 2, and the arc-shaped bosses 2 are evenly distributed around the circumference set, thereby forming a convex-concave stepped structure; the opening structure of the bearing body 1 is: an upper boss 3 and a lower boss 4 extend between the left and right ends of the bearing body 1, and the shape of the upper boss 3 is The shape of the arc is the same as the radius of curvature of the outer ring surface of the bearing body, and the shape of the lower boss 4 is the same arc shape as the radius of curvature of the inner ring surface of the bearing body.

[0015] The diameter of the outer ring of the bearing body is 150-800 mm, the diameter of the inner ring is 100-600 mm, and the thickness is 3-5 mm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com