High-performance regulating valve with floating valve base

A floating valve seat, high-performance technology, used in valve devices, engine components, cocks including cut-off devices, etc. Rod flexibility and other issues, to achieve the effect of simple structure, good self-sealing performance and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

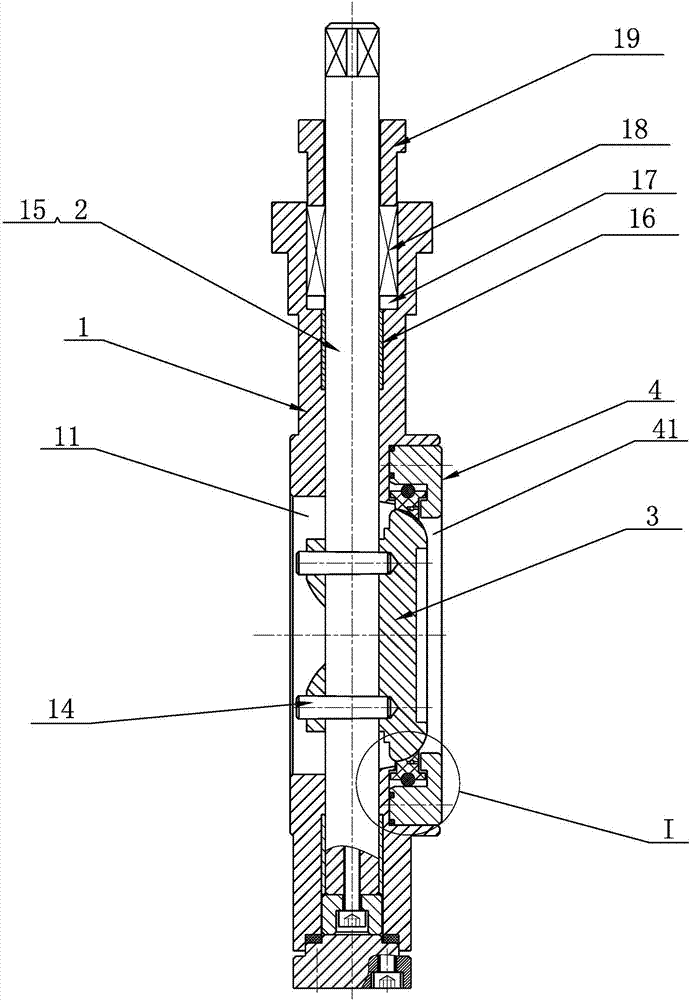

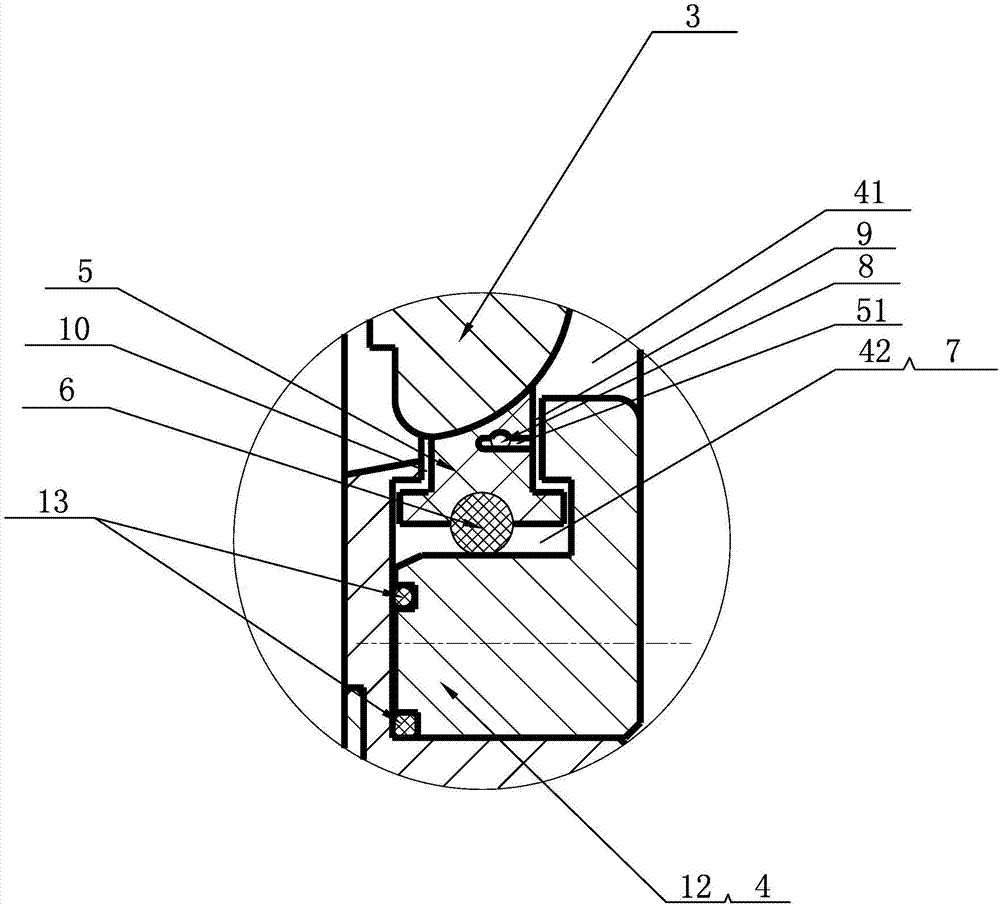

[0015] see figure 1 and figure 2 , a floating seat high-performance regulating valve disclosed in the present invention, comprising a valve body 1, a valve stem 2 and a valve plate 3, the valve body 1 is provided with a valve cavity 11, and the valve plate 3 is installed in the valve cavity 11 , the lower end of the valve stem 2 is inserted into the valve chamber 11, and the lower end of the valve stem 2 is detachably connected to the valve plate 3; one end of the valve body 1 is provided with a pressure plate installation groove 12, and a positioning plate is arranged in the pressure plate installation groove 12 Pressing plate 4, a medium through hole 41 is provided in the middle of the positioning pressing plate 4, a sealing seat installation groove 42 is provided on the inner wall surface of the medium through hole 41, and a sealing seat installation groove 42 is installed in the sealing seat installation groove 42 for connecting with the valve plate 3 A sealed floating s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap