Detection device and method for multi-electrode array corrosion sensor micro current

A technology of corrosion sensors and multi-electrode arrays, applied in the field of circuits, can solve the problems of being unsuitable for array corrosion current measurement and difficult to meet uA level current measurement requirements, and achieve the effect of eliminating the offset voltage of operational amplifiers and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

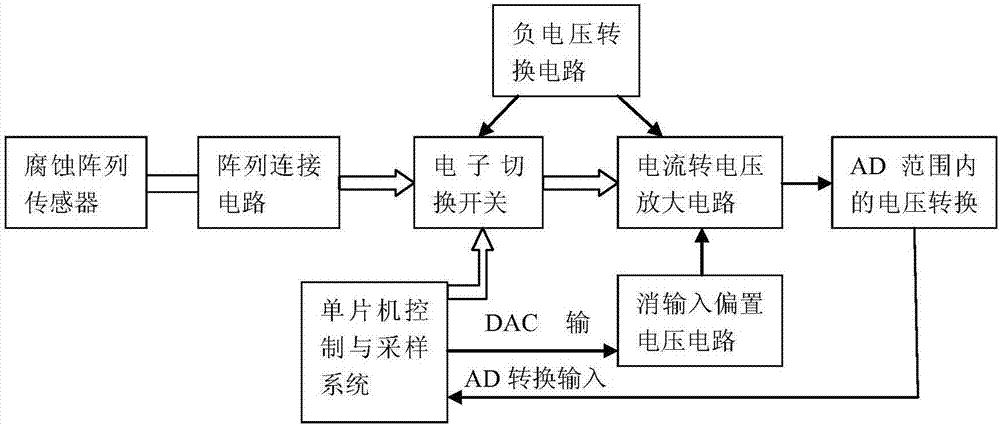

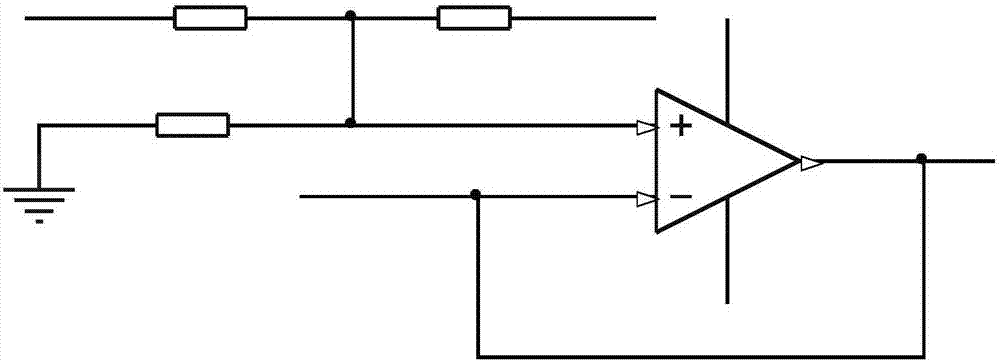

[0051] 1. The present invention provides a detection device for the tiny current of a multi-electrode array corrosion sensor, including a sequentially connected corrosion array connection circuit, an electronic switch circuit, a current-to-voltage amplification circuit, a voltage conversion circuit in the AD range, and a single-chip microcomputer control and Sampling system; the single-chip control and sampling system is connected with the current-to-voltage amplifying circuit through the input bias voltage elimination circuit of the operational amplifier, and the single-chip control and sampling system is also connected with the electronic switch circuit, and the electronic switch circuit and the current-to-voltage amplification The circuit is connected with the negative voltage conversion circuit at the same time.

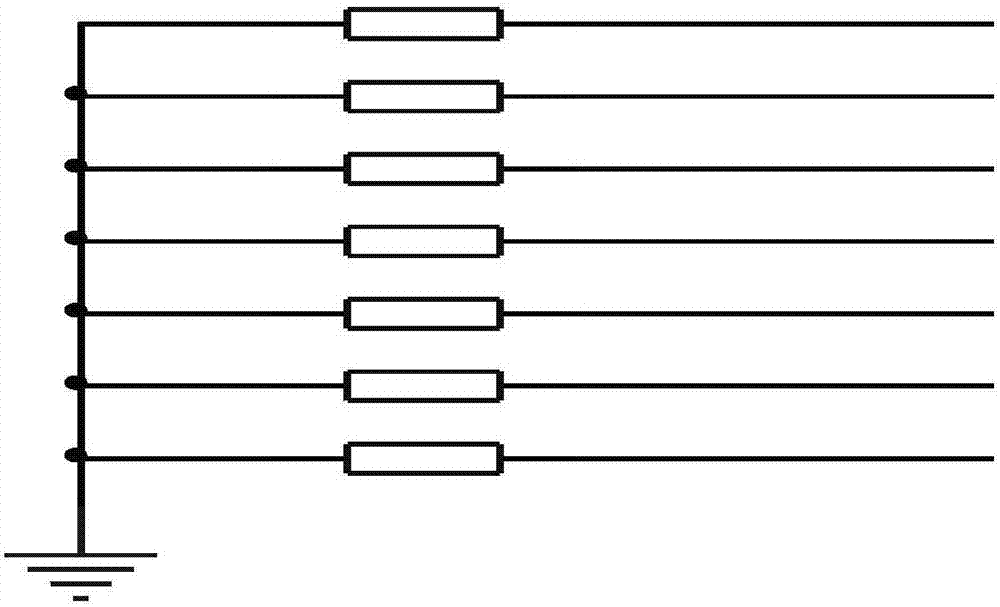

[0052] The corrosion array connection circuit includes several corrosion array sensors and an array connection circuit, and the corrosion array sensor includes at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com