Virtual modeling method for particle reinforced composite material

A composite material, particle-enhanced technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of time-consuming, cumbersome geometric modeling, affecting the process of building 3D models of complex materials, and reduce geometric construction. Mode time, the effect of reducing dependence and necessity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

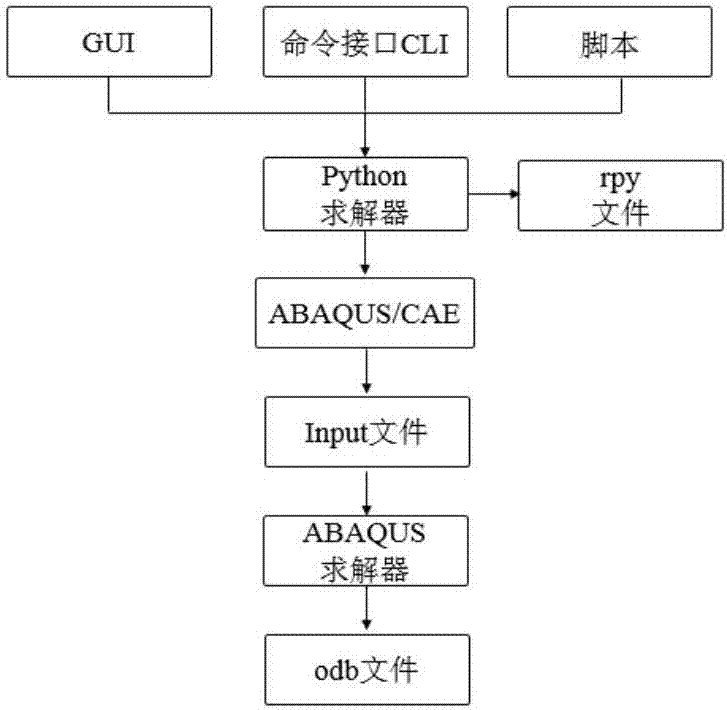

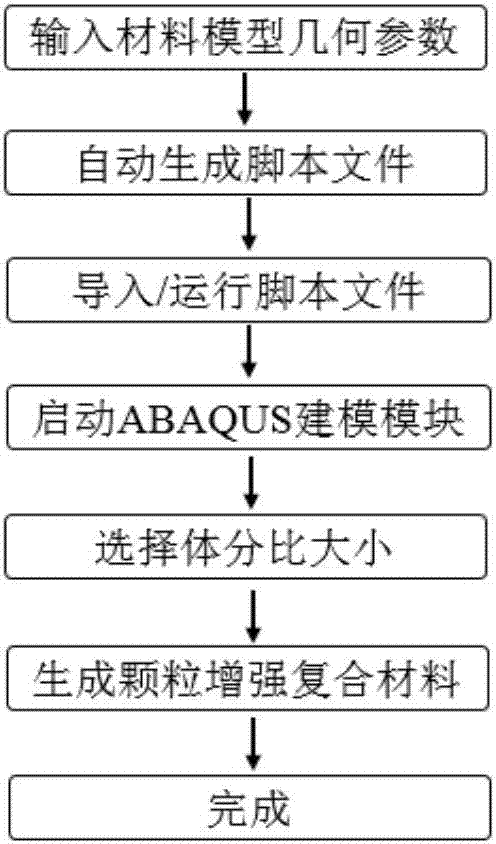

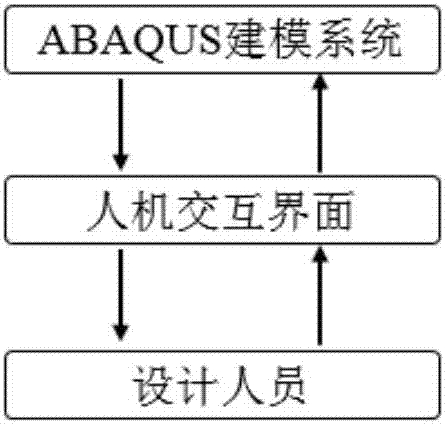

[0024] Such as figure 2 Shown, the virtual modeling method of particle reinforced composite material of the present invention, based on ABAQUS platform and python language, comprises the following steps:

[0025] Step (1), the determination of the three-dimensional geometric size of the material: assuming that a number of spherical particles are uniformly distributed in a cube with a side length of 9i, the side length of 9i is divided into 9 equal parts, and each division point is a center of gravity of a spherical particle, then a There are 10 spherical particles evenly distributed on the side. The percentage of the volume of spherical particles to the volume of the whole cube is the volume ratio of the material. Let the volume ratio of the material be ρ. Calculate the volume ratio of the material by controlling the diameter of the spherical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com