A built-in vibrating magnetic separator

A technology of magnetic separator and vibrating motor, which is applied in the direction of magnetic separation, solid separation, cleaning method using liquid, etc. It can solve the problems such as the inability to adjust the position and amplitude of the media box, the high blocking rate of the media box, and the high power of the motor, etc., to achieve Effects of avoiding clogging, reducing weight, and enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

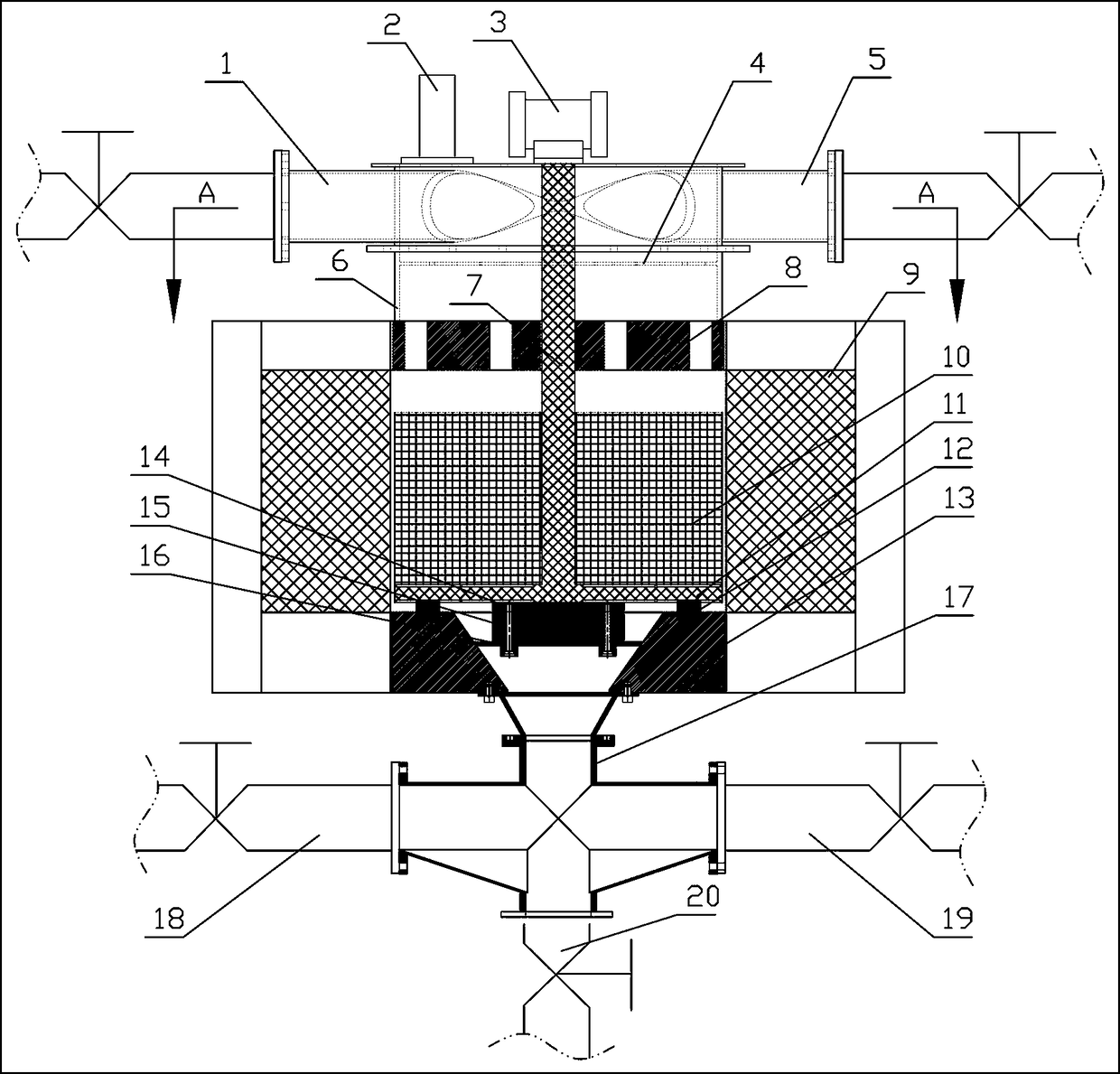

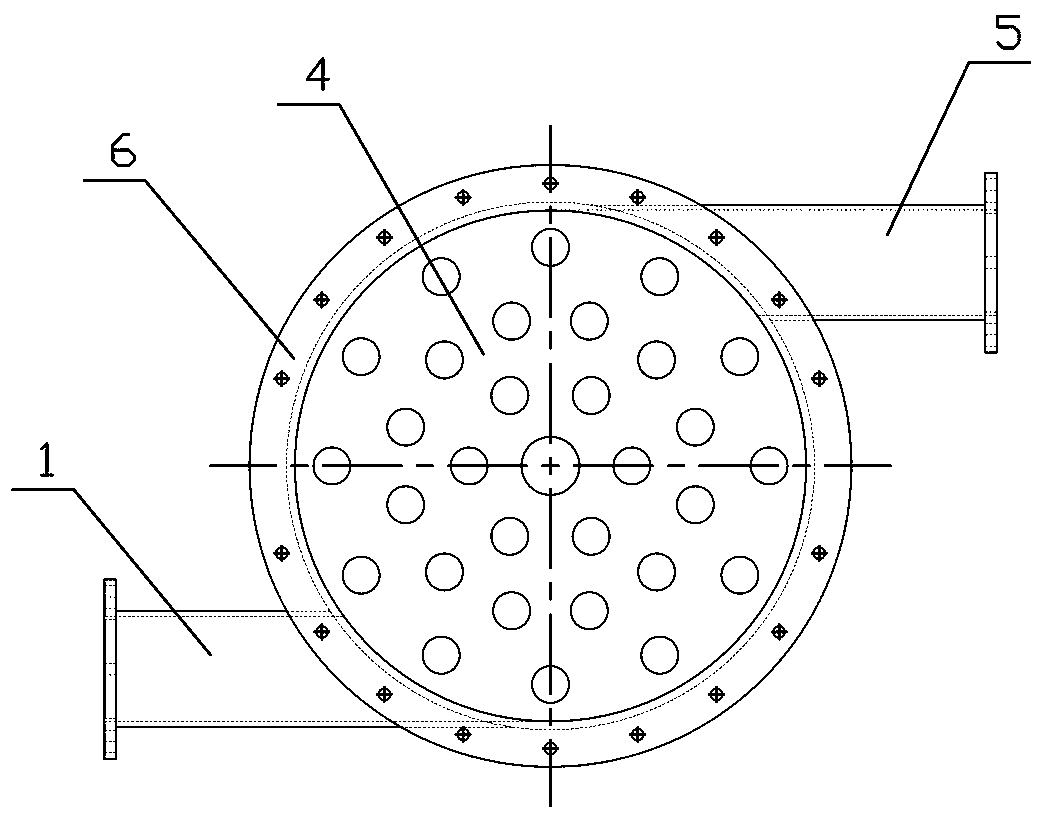

[0012] see Figure 1-2 , the present embodiment has a hollow casing 6, the top of the casing 6 is equipped with an exhaust pipe 2, the top of the casing 6 is provided with a feed pipe 1 and a water inlet pipe 5 communicating with the casing 6, and the inside of the casing 6 is from Screening net 4, upper magnetic pole 8 with several through holes, medium box 10, medium box base 11 and lower magnetic pole 13 are installed in order from top to bottom, and excitation coil 9 is installed in the upper and lower magnetic pole areas outside the housing 6. The middle part of the magnetic pole 13 is provided with a slag discharge hole, and a vibrating motor 3 is also installed above the housing 6, and the vibrating motor 3 is connected with the vibrating transmission shaft 7, and the vibrating transmission shaft 7 passes through the screen 4 and the upper magnetic pole in turn. 8. The medium box 10, the end of the vibration transmission shaft 7 is fixed on the medium box base 11, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com