Air channel control system suitable for counter-pressure casting

A technology of differential pressure casting and gas path control, applied in the field of differential pressure casting, can solve problems such as poor gas pressure control, unreasonable gas channel design, unsatisfactory casting molding effect, etc., and achieve good practicability, popularization, and structure Simple, small gas pressure fluctuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

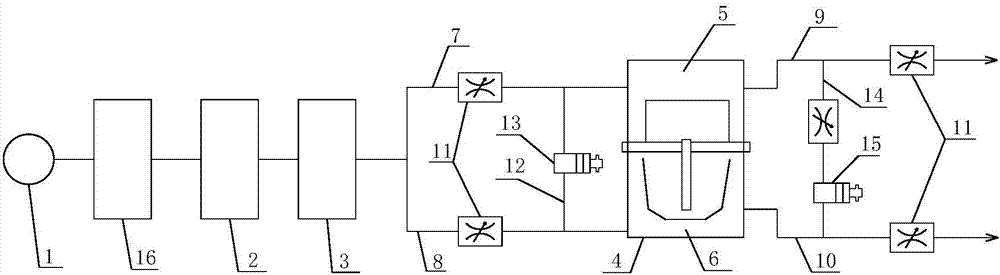

[0014] Such as figure 1 As shown, the present invention provides a differential pressure casting air circuit control system, which is suitable for differential pressure casting. The system includes an air compressor 1, a compressed air oil-water separator 2, a dryer 3, an air intake system, a differential pressure casting mold 4 and an exhaust system connected in sequence. The air compressor 1 provides an air source for the entire system, and the compressed air oil-water separator 2 is used to separate the oil in the compressed air, so that the compressed air entering the differential pressure casting mold 4 is clean and pure, ensuring that the differential pressure casting mold 4 While extending the service life, the molding quality of castings is guaranteed. The dryer 3 is used to filter the compressed air provided by the air compressor to remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com