Double-inclined hole machining device for numerical control machining center

A processing device and processing center technology, applied in the direction of positioning devices, clamping devices, metal processing equipment, etc., can solve the problems of unguaranteed drilling angle and processing accuracy, and required distance, etc., to achieve convenient operation, labor saving, drilling The effect of reducing the time for hole processing and ensuring distance accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

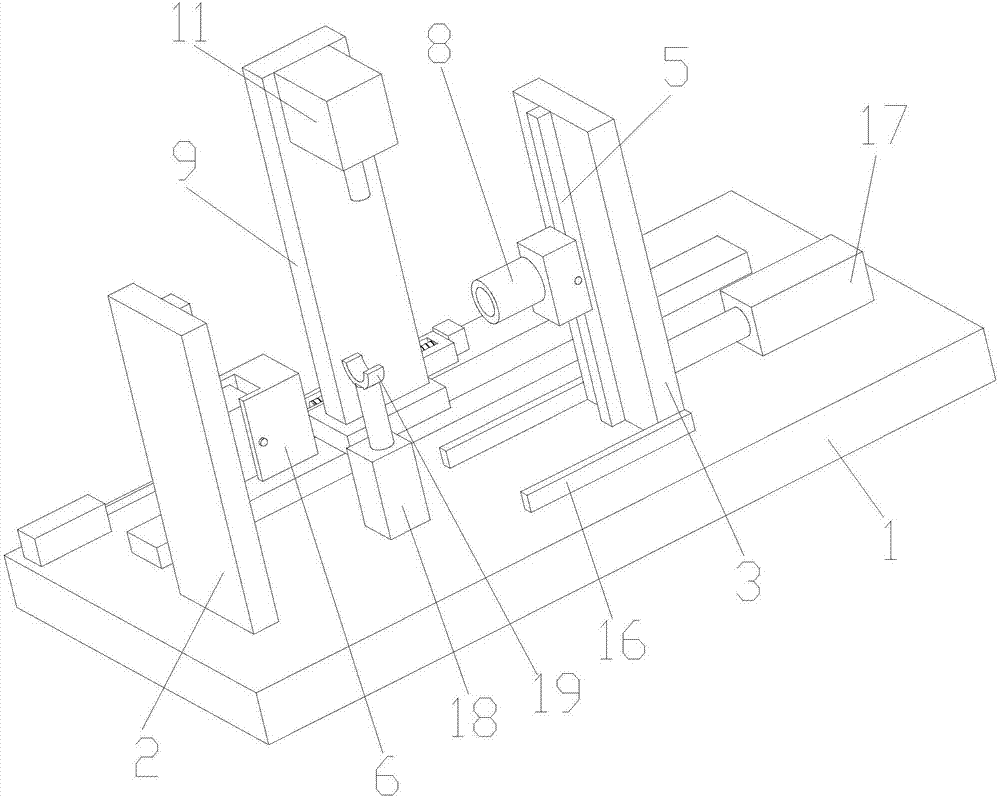

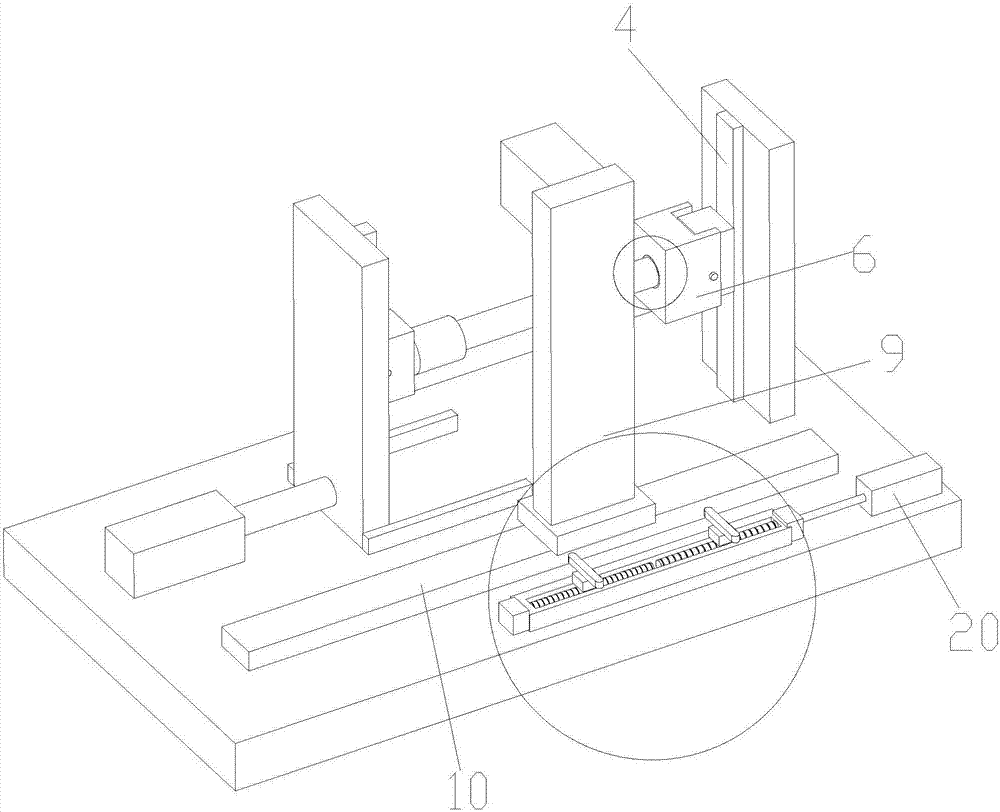

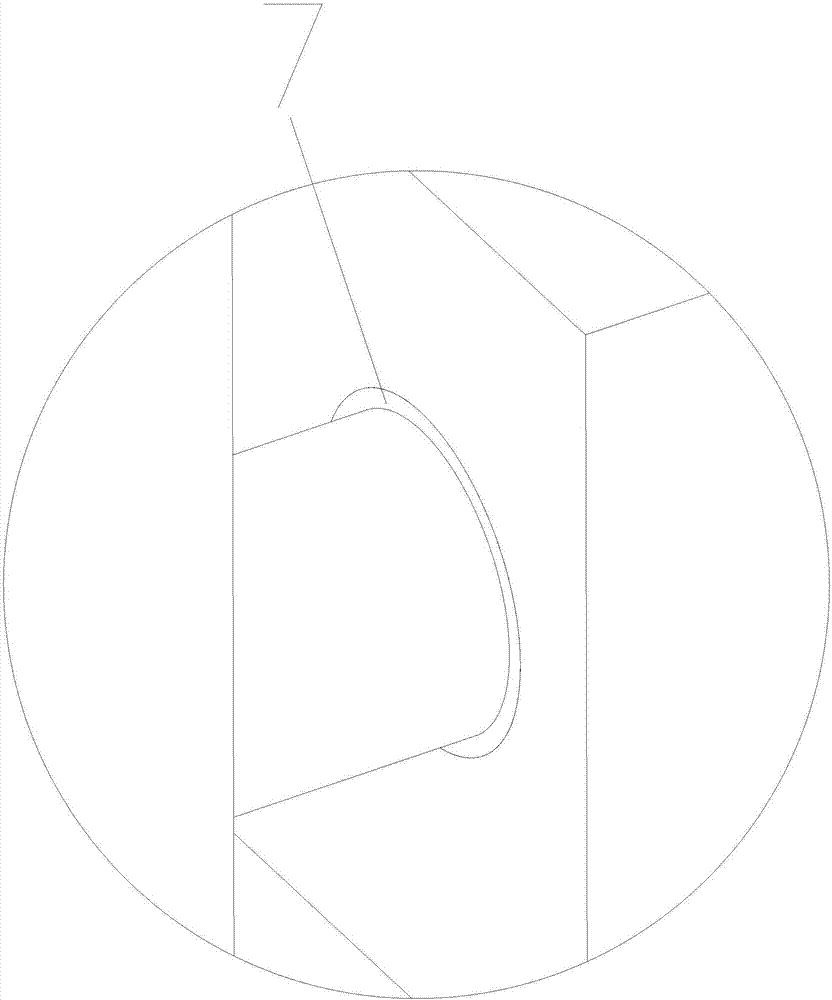

[0018] as attached Figure 1-4 The shown double slant hole processing device for a CNC machining center of the present invention includes a base 1, a first support plate 2, a second support plate 3, a first slide rail 4, a second slide rail 5, a rotating Block 6, electromagnet ring 7, positioning pipe 8, support assembly, drilling base 9, moving guide rail 10, drilling mechanism 11, measuring seat 12, screw mandrel 13, proximity switch 14 and motor 15; The first support plate 2 and the second support plate 3 are arranged oppositely, and the second support plate 3 is slidably arranged on the base 1; the first support plate 2 and the second support plate 3 are respectively provided with There are a first slide rail 4 and a second slide rail 5; the slider of the first slide rail 4 is provided with a rotatable rotating block 5; the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com