Technological method for treating heat insulation layer surface of engine

A technology of surface treatment and heat insulation layer, applied in manufacturing tools, metal processing equipment, mechanical roughness/irregularity measurement, etc., can solve problems such as large dust, polluted environment, low efficiency, etc., achieve physical and mental health assurance, and improve automation Level, the effect of ensuring the quality of surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

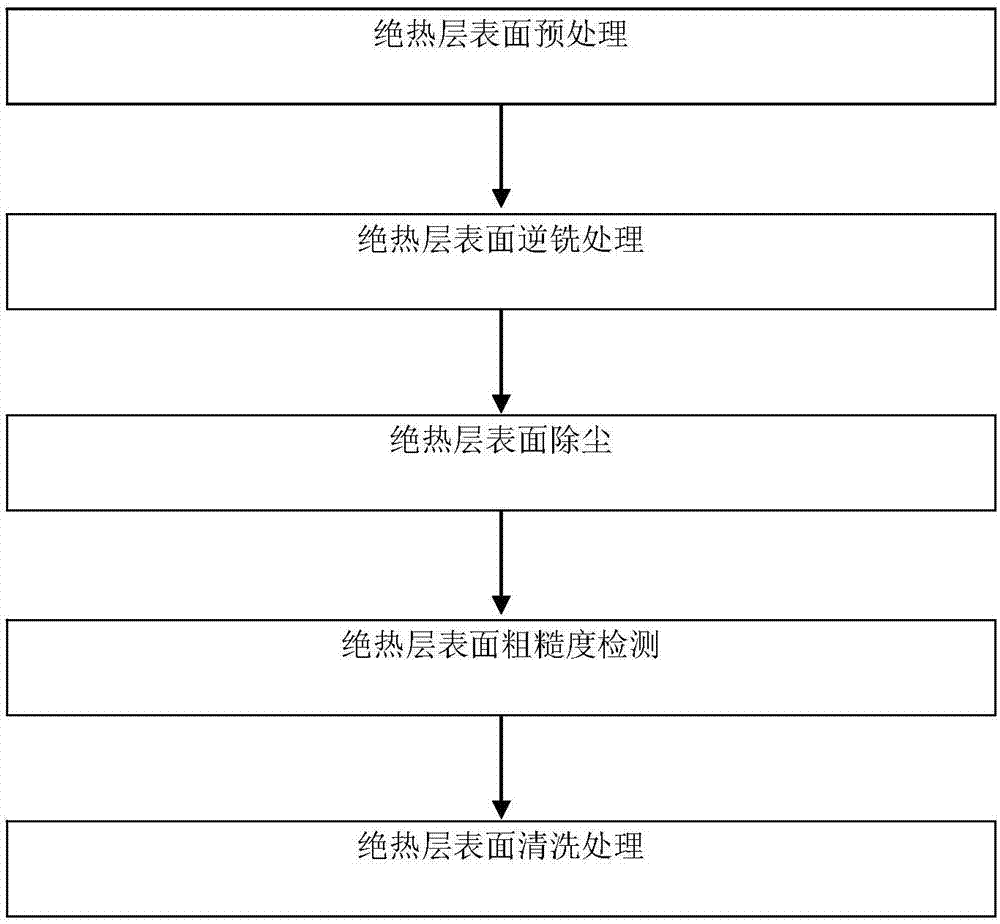

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in combination with specific embodiments.

[0017] (1) Surface pretreatment of the heat insulation layer: Clean the surface of the engine heat insulation layer with solvents such as ethyl acetate or acetone to remove small molecular substances attached to the surface of the heat insulation layer, so that the surface is moderately swollen and the heat insulation layer is softened.

[0018] (2) Up-cut milling treatment on the surface of the heat insulation layer: according to the surface treatment requirements, select a milling cutter with a suitable specification. Under the speed of 2200r / min-2800r / min, the milling cutter plans the walking path according to the surface shape, and performs up-cut milling treatment on the surface of the heat insulation layer. . There is a height difference of 0.1mm between the profiler and the milling cutter installed coaxially with the milling cutter, and the height difference is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com