Vehicle body fixture flexible switching platform

A flexible and platform technology, applied in the field of flexible switching platform for body fixtures, can solve the problems of long tooling switching cycle, complex platform design, and long processing cycle for new and old models, and achieve short tooling preparation cycle, small trial batches, and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

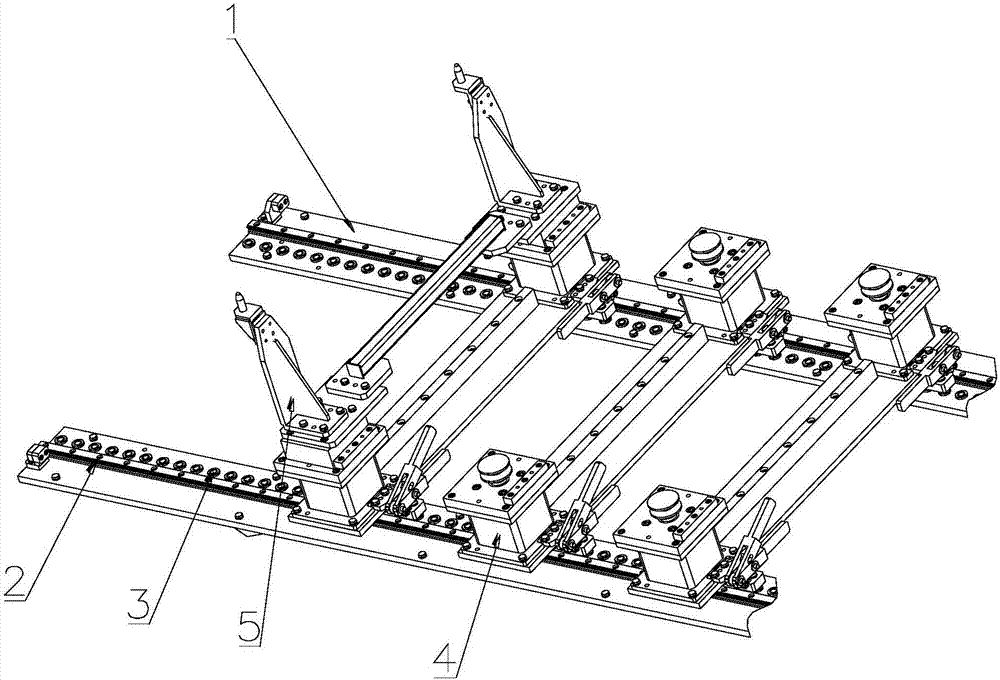

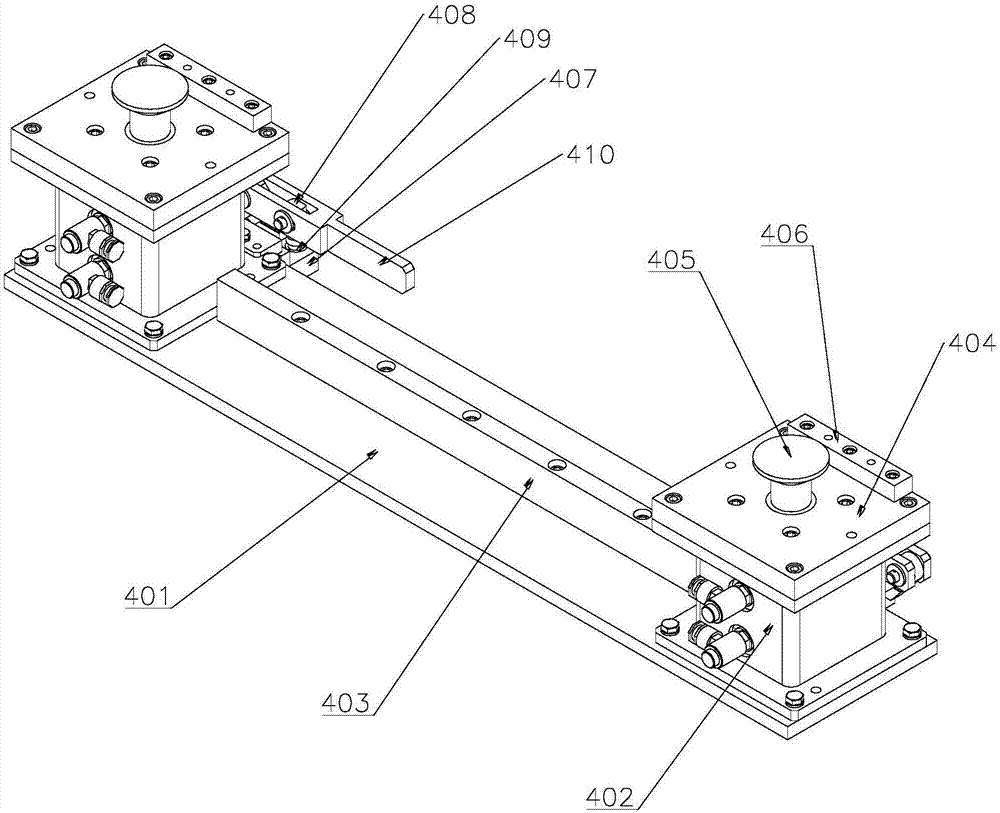

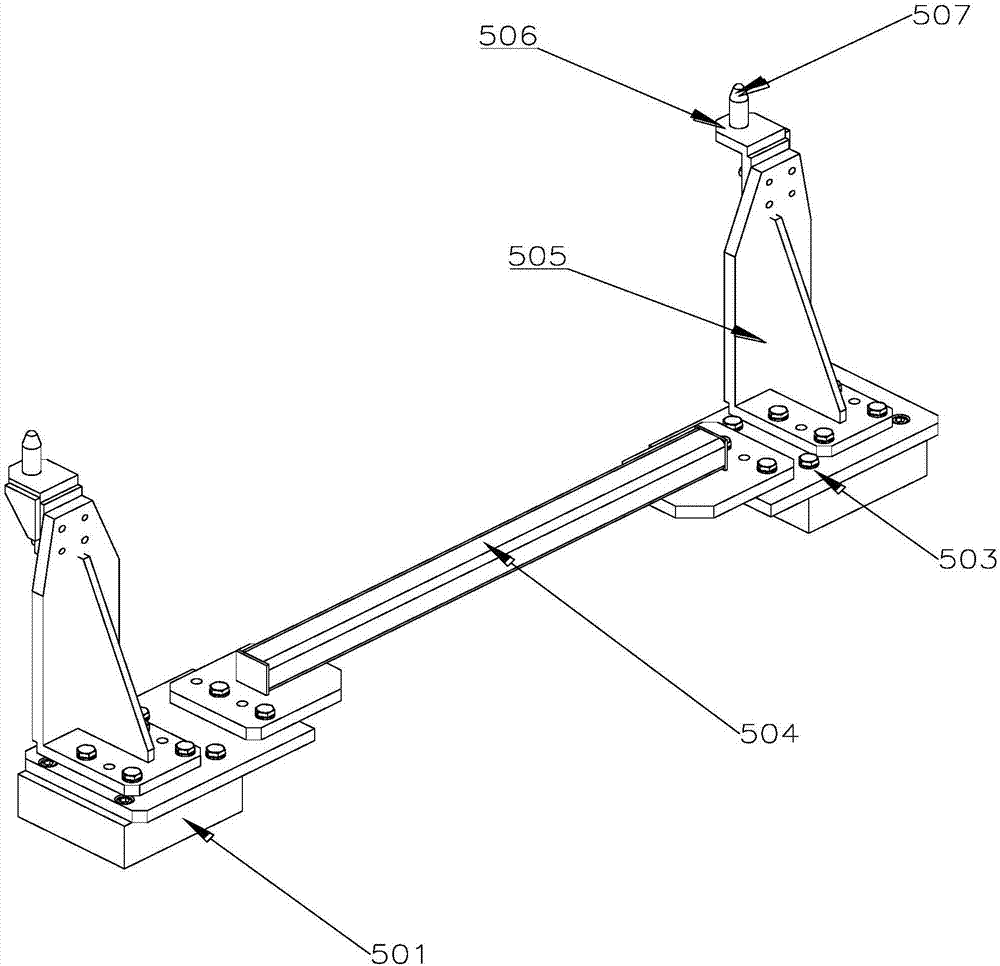

[0016] Such as figure 1 As shown, a flexible switching platform for body fixtures is used for the assembly and clamping of automobile floor plates in the trial production line based on a two-story steel structure platform. The first floor of the two-story steel structure platform is equipped with body assembly stations and main work stations , an additional station, a repair station, and an output station. The flexible switching platform for the vehicle body fixture is set at the vehicle body assembly station, including two flexible mounting plates 1, which are arranged in parallel in the horizontal direction, and on the two flexible mounting plates 1 Parallel rails 2 and symmetrical positioning holes 3 arranged along the direction of the rails 2 are respectively provided. A plurality of flexible switching me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com