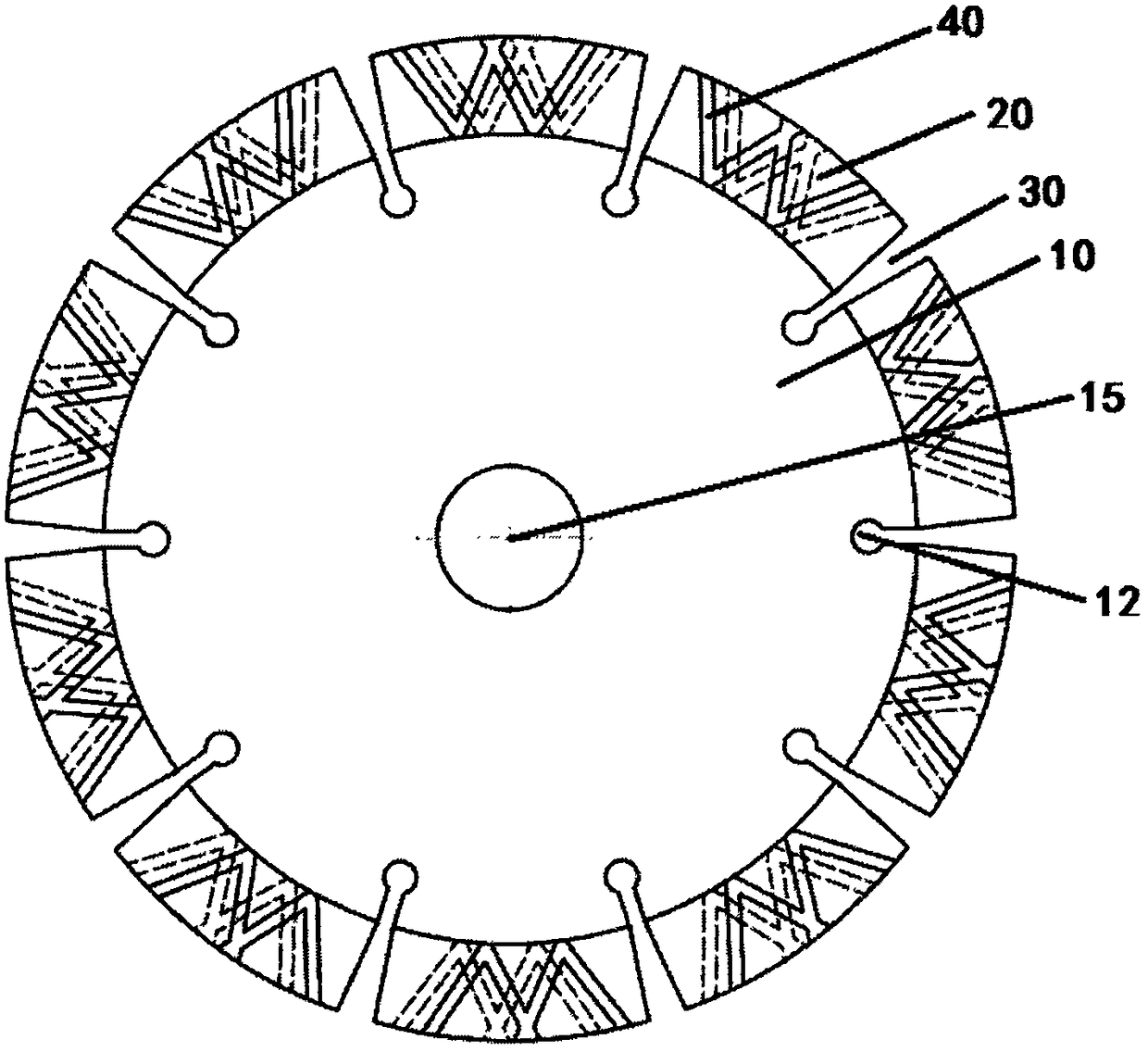

Double-sided sintered w-shaped groove diamond tool and preparation method thereof

A diamond tool and diamond technology, applied in the field of diamond tools, can solve problems such as the weakening of the carcass surface and the reduction of wear resistance, and achieve the effects of preventing surface cracks and cracking, improving cutting efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepared by the following method Double-sided sintered W-groove diamond tools. The manufacturing method of the W-groove diamond tool includes the following sequence: batching-simplification-secondary powder filling cold pressing-pressureless sintering-wiping sheet punching-painting-sharpening-inspection, packaging and storage.

[0030] 1) Ingredients of diamond and metal bond: expressed in weight percent, EXD606 alloy 30%, LFP alloy powder 10%, tin powder 8%, nickel powder 10%, cerium-copper alloy powder 1%, copper powder 41%. The diamond concentration added in the metal bond is 0.8ct / cm 3 , diamond particle size 35 / 40 accounts for 20%, 40 / 50 accounts for 50%, 50 / 60% accounts for 30%, mixed into molding materials, using a three-dimensional mixer, and the mixing time is 120 minutes.

[0031] 2) Simplified manufacturing: add the granulating agent to the mixed molding material for mixing and simple granulation.

[0032] 3) Cold pressing: Adjust the tooling mold, first ...

Embodiment 2

[0036] Prepared by the following method Double-sided sintered W-groove diamond tools. The manufacturing method of the W-groove diamond tool includes the following sequence: batching-simplification-secondary powder filling cold pressing-pressureless sintering-wiping sheet punching-painting-sharpening-inspection, packaging and storage.

[0037] 1) Ingredients of diamond and metal bond: expressed in weight percent, EXD606 alloy 28%, LFP alloy powder 12%, tin powder 8%, nickel powder 10%, cerium-copper alloy powder 1%, copper powder 41%. The diamond concentration added in the metal bond is 0.8ct / cm 3 , diamond particle size 35 / 40 accounts for 20%, 40 / 50 accounts for 50%, 50 / 60% accounts for 30%, mixed into molding materials, using a three-dimensional mixer, and the mixing time is 120 minutes.

[0038] 2) Simplified manufacturing: add the granulating agent to the mixed molding material for mixing and simple granulation.

[0039] 3) Cold pressing: Adjust the tooling mold, first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com